|

ABSTRACT

A

significant number of new manufactured houses

built to HUD code and located in the hot, humid

Southeast are experiencing moisture problems.

Soft wallboards, buckled floors, damaged wood

molding and extensive mold growth are the most

common symptoms. These problems do not respond

to the standard service and repair strategies

for water intrusion

At

the request of four manufacturers, over twenty-five

such moisture damaged homes were investigated

in 1999 and 2000 to determine likely causes.

One time blower door, duct tightness and pressure

differential measurements were performed on all

homes. Field data on ambient, crawlspace, belly

and house temperatures and RH were collected on

a few of the homes. Recommendations and reports

were prepared for the manufacturers service, production

and design staff. Field repairs were performed

in most of these homes.

A

generalized theme existed in the houses investigated.

Lowered air conditioner thermostat

setting (typically 68-73oF),

below the ambient dew point.

Negative pressures across

the envelope from high supply duct leakage

(cfm @25Pa > 10 per 100 square feet of conditioned

floor area), inadequate return air paths, interior

door closures, exhaust fans or a combination

thereof.

Inadequate moisture removal

from disconnected return ducts, fans always

on (air handler or ventilation), inadequate

drainage of condensate, oversized air conditioner

or a combination thereof.

Moisture diffusion from

the ground into the house because of poor site

drainage, inadequate crawl space ventilation,

tears in the belly board, or a combination thereof.

Vapor retarder in the wrong

location i.e. vinyl or other impermeable

wall or floor coverings located on the colder

surfaces.

Recommended

solutions provided to the manufacturers to eliminate

moisture problems include:

Maintain air conditioner thermostat

above the ambient dew point (at least 75oF

)

Eliminate long term negative

pressures created by air handler fans or ventilation

equipment.

Tightly seal all ductwork and

provide adequate return air pathways.

Enhance moisture removal from

the conditioned space by correct sizing and

maintainence of equipment

Eliminate ground source water

and provide adequate moisture barrier for the

floor assembly

If possible, remove vapor barriers

located on the wrong surfaces.

Work

is continuing to determine if these steps will

be sufficient to prevent problems even in the

presence of vapor barriers in the wrong locations

for the hot, humid climates that are preferred

by manufacturers and customers.

INTRODUCTION

Of

the two million homes built in the U.S. in 1999,

over 18.5% were built in factories to the code

of the U.S. Housing and Urban Development (HUD).

In 2000, one out of six new single-family housing

starts were manufactured homes. Last year, the

industry shipped 250,550 homes from 280 manufacturing

facilities. Over 19 million people, about 8 percent

of the U.S. population, live full-time in over

8 million manufactured homes (Manufactured Housing

Institute 2000a). These manufactured homes are

one of the most affordable single family detached

housing available any where in the world, generally

costing less than $35/ ft2 plus land

costs for centrally air conditioned and heated

homes with built in kitchens. Available in all

parts of the country, manufactured homes are more

popular in the southern and western U.S. where

land is still plentiful and in rural areas elsewhere.

In

1999, the U.S. Department of Energy (DOE) competitively

selected the Florida Solar Energy Center (FSEC)

as the Building America Industrialized Housing

Partnership (BAIHP) team leader. This group’s

primary function is to serve the manufactured

housing industry by fostering technology-based

innovations that will increase energy efficiency

through a systems engineering of the whole house.

The systems engineering approach considers the

interaction between the building site, envelope,

and mechanical systems, as well as other factors.

It recognizes that features of one component in

the house can greatly affect others and it enables

the teams, including the manufacturers and suppliers,

to incorporate energy-saving strategies at no

extra cost. System trade-offs, like the tightened

shell that enables an engineer to recommend a

smaller HVAC system, can improve the quality and

performance of a home without affecting its first

cost to the builders or to the consumers. The

BAIHP team has three specific objectives in mind

while serving the industry:

1.

Cost effectively reduce the heating,

cooling and hot water energy usage of industrialized

housing and portable classrooms by up to 50%

while enhancing indoor air quality, durability

and manufacturing productivity.

2.

Assist in the construction of thousands

of energy efficient industrialized houses annually.

This goal is acomplished by touring production

facilties to try and pin-point problem areas

and work with the manufacturers to resolve the

problems, and provide design assistance.

3.

Make our team members pleased and proud

to be working with us.

Industrialized

housing includes manufactured housing (built to

the HUD code), modular housing (factory built

housing modules assembled on site) and production

housing (site built housing produced in a systematic

manner). Currently, there are five HUD-code manufacturers

that are BAIHP team members. These include:

Cavalier Homes

Clayton Homes

Fleetwood Homes

Palm Harbor Homes

Southern Energy Homes

The

driving force that has encouraged these builders

to become team members varies from builder to

builder, however there is a general underlying

theme. A number of their homes built for the

hot and humid climate (built according to HUD-code

specifications) have experienced various degrees

of building failure due to moisture. A

subtask of the effort with the DOE Building America

Program is entitled “Moisture Research”.

In this endeavor, FSEC will attempt to help team

members to eliminate moisture problems plaguing

HUD Code homes in the Southeast by “…conducting

diagnostic tests in problem homes, fixing problem

homes, evaluating the effectiveness by conducting

pre/post fix short term tests, and related activities…”

The

HUD-Code Home

What

is the difference between a manufactured home,

a modular home and a panelized home? Many types

of structures are built in a factory and designed

for long-term residential use. Manufactured and

modular home units are built in a factory, transported

to the site location and installed. Panelized

and pre-cut homes, essentially flat units (factory-built

panels or factory-cut building materials) are

transported to the site location and assembled.

The major difference is that manufactured homes

are federally regulated by the HUD Code under

Title 24 CFR 3280. The HUD Code provides the

design and construction requirements for the complete

production of the entire home in the factory,

with some modifications permitted for on-site

completion. Modular, panelized and pre-cut homes

fall under the auspice of the model building code

enforced in the jurisdiction where the home will

be located. These codes can include the BOCA

National Building Code, the ICBO Uniform Building

Code, the Southern Standard Building Code or the

ICC One- and Two-Family Dwelling Code.

The

Construction Process and Setup

The

process of constructing a manufactured home is

very different from the conventional site built

home – the home is built from the inside

out as it travels down an assembly line. A steel

chassis is constructed and the floor assembly

(containing plumbing, wiring, and duct work) is

attached. Floor coverings, interior walls, plumbing

fixtures, and furnace are installed. The exterior

walls with the interior finish and insulation

are hoisted into place and attached to the floor.

The finished ceiling assembly is then lifted from

the construction jig and lowered onto the home

(figure 1).

As exterior sheathings and coverings are attached,

a flurry of interior activities continues within

to provide finishing touches. The newly constructed

assembly is then moved to the operational test

site where the various plumbing and electrical

systems are checked.

Figure

2 shows a typical HUD-code home just produced leaving

the factory. These homes have a permanent steel

chassis with axles attached below the floor.

After production the homes could travel a few

hundred miles, hauled by a truck, before set up

in its final location. The homes are set upon

blocks or piers and the steel frame chassis is

firmly anchored to the ground. A vented skirting

conceals the underside of the home.

The

Duct System

Manufactured

homes are typically heated or cooled by a forced

air system employing ductwork, which delivers

hot or cold air from the air handler unit (AHU).

The ductwork may be located in the attic or in

the belly cavity of the home. Figure

3 shows the ducts in the belly, supplying

conditioned air to all rooms through floor vents.

This is a very common and inexpensive system that

is used in manufactured homes. The ducts are

typically made out of aluminum or fiberglass trunk

lines which supply air to the floor registers

through in-line boots or through flex ducts, which

terminate to perimeter registers on the floor.

The most common method of sealing the various

joints and connections is with a foil tape.

Multi-section

homes will also have a section of the ductwork

that is connected during the setup operation.

A flexible duct is used to connect the supply

sections together in the attic or in the crawlspace.

These connections are usually made with duct tape

and/or a tie strap. (Note: the authors have seen

three out of twenty-five instances during the

course of this project where there has been complete

or nearly complete separation of this connector

duct.)

The

Ventilation System

All

HUD-code homes are required to have a ventilation

system installed. Title 24 CFR Part 3280.103b

‘Light and ventilation’ states that…

“Each

manufactured home shall be capable of providing

a minimum of 0.35 air changes per hour continuously

or at an equivalent hourly average rate. The

following criteria shall be adhered to.

Natural

infiltration and exfiltration shall be considered

as providing 0.25 air changes per hour.

The

remaining ventilation capacity of 0.10-air

change per hour or its hourly average equivalent

shall be calculated using 0.035 cubic feet

per minute per square foot of interior floor

space. This ventilation capacity shall be

in addition to any openable window area.

The

remaining ventilation capacity may be provided

by: a mechanical system, or a passive system,

or a combination passive and mechanical system….”

Currently,

there are two main types of ventilation systems

that are employed by the manufacturing housing

industry to meet the 0.10 air change per hour

requirement. Both types are used in the hot and

humid climate; an exhaust only system that is

located in a hallway or utility room and an outside

air supply system that is ducted from the roof

to the return airside of the air handler fan.

The exhaust ventilation system is manually controlled

with a simple on-off switch. The outside air

supply system is linked to the operation of the

air handler and controlled with an automatic damper

(if applicable).

MOISTURE

PROBLEMS IN MANUFACTURED HOMES

Moisture

problems are being experienced by a significant

number of manufactured homes in the hot, humid

climate of the Southeast United States. According

to the Manufactured Housing Research Allaince

(MHRA), solving moisture problems is the highest

research priority of the HUD code industry. Moisture

problems (Figure 4)

include extensive mold, soft wallboards, buckled

floors, damaged wood molding and trim, and high

relative humidities in the home. Frequently,

these homes have a high air-conditioning bill

as homeowners attempt to increase comfort by lowering

the thermostat temperature. (Note: each degree

F drop in temperature causes an approximate 10%

increase in cooling costs. The BAIHP team has

investigated over 25 problem homes and has found

that the problems are caused by the following

factors acting individually or in combination

Lowered air conditioner thermostat

setting (typically 68-73oF), well

below the ambient dew point.

Negative pressures across

the envelope from high supply duct leakage

(cfm @25Pa > 10 per 100 square feet of conditioned

floor area), inadequate return air paths, interior

door closures, exhaust fans or a combination

thereof.

Inadequate moisture removal

from disconnected return ducts, continuous operation

of air handler or exhaust fans, inadequate removal

of condensate, oversized air conditioner, poorly

maintained equipment or a combination thereof.

Moisture diffusion from

the ground into the house because of poor site

drainage, inadequate crawl space ventilation,

tears in the belly board, or a combination thereof.

Vapor retarder in the wrong

location i.e. vinyl or other impermeable

wall or floor coverings.

Building

Science Basics For Moisture Plagued Homes

In

the hot and humid Southeastern U.S., the outside

air is consistently above a dewpoint of 75oF

during the summer months. If the homeowner decides

to keep the interior temperature of the home below

75oF, in an effort to maintain comfort,

or if an interior surface is cooled below the

exterior dewpoint temperature, then when moisture-laden

outside air comes into contact with cold inside

surfaces, condensation occurs. If it condenses

behind an impermeable surface such as vinyl flooring

or vinyl wallpaper, wall board damage, floor buckling

problems and mold problems can result. There

are six main sources that we have seen in our

investigations of ~25 problem homes with moisture

damage of “unknown” causes.

Interior

Temperature Below Outside Dewpoint (100% of the homes investigated)

Homeowners

want to be comfortable in their homes. Thermal

comfort is, in a simplified form, a function of

the temperature, humidity and the physical activity

of an individual (Fanger 1972). In most homes,

the only “control” feature is that of

the thermostat. The common perception is that

lowering the temperature will provide the cooling

comfort desired. The HVAC supplier/installer

wants to ensure that the homeowner has a unit

that is oversized to prevent callbacks of high

interior temperatures or home owner precieved

excessive run-times of the air conditioning system.

Oversizing can cause several problems that are

detrimental to the house and occupant comfort

(Karg, R. and Krigger J. 2000).

The unit is not operating long

enough to provide dehumidification. Dehumidification

is acomplished by passing return air over the

cooling coil.

The interior house temperatures

can be lowered to a point far below the ambient

air temperature dewpoint. This can lead to

condensation on interior surfaces, with it’s

attendant material degradation and mold growth.

Typical summer dewpoint temperatures range between

70 and 80 degrees F for most of the hot, humid

South, especially near coastal regions.

The oversized unit has a larger

blower fan, which exacerbates duct leakage and

pressure differential problems associated with

the forced air system.

Negative

pressures across the envelope (100% of the homes investigated)

Negative

pressure is the driver that brings warm moist

exterior air into the building through every crack,

crevice, hole or opening that exists. The negative

pressure field may encompass the entire building

or there may be zones within the building that

experience negative pressures created by inadequate

return air paths, or interior door closures. For

example, supply duct leakage and/or exhaust fans

may create negative pressures in the entire house,

while door closure may create negative pressure

in a single room or zone of the house. It is

important to note that we are talking about miniscule

amounts of negative pressures – on the order

of 1 to 3 Pascals. However, over time, even these

tiny air pressures can lead to serious damage

(Odom, 1996).

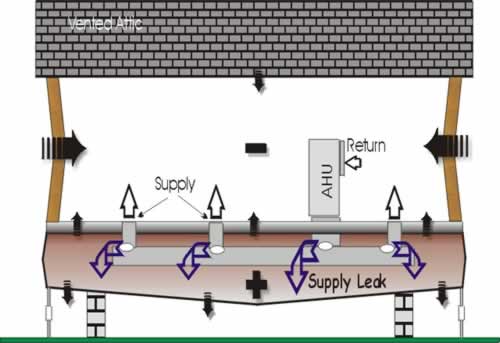

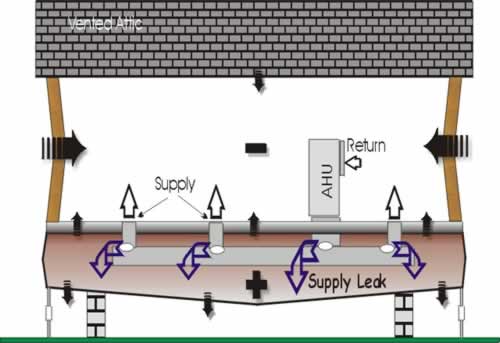

Duct

leaks and return air pathways (100% of the homes investigated)

One

of the biggest causes of moisture problems in

manufactured homes, in hot and humid climates,

is leakage from the supply ducts. In manufactured

housing, the leakage is often caused by poor design

and construction practices which leaves holes

at the connection points of the AHU to the main

trunk, the boots (or risers) to the trunk, the

boots to the supply registers, end caps, cross-over

duct connections and other connection points in

the duct work. When the AHU moves air, some of

it leaks into the belly and eventually to the

outside through tears in the belly board. This

loss of air creates a negative pressure inside

the house and a positive pressure in the belly

as schematically shown in figure

5. The negative pressure draws outside

or attic air into the house through the numerous

cracks and crevices connecting the inside of the

house to the outside or the attic. If this outside

air is cold and dry, like it is in the wintertime

in the Northern U.S. it will increase the heating

energy use and occupant discomfort. This situation

would not rot the home in this climate but it

will in the hot, and humid Southern U.S..

Another

aggravating factor is the lack of return air transfers

when interior doors are closed. In many manufactured

and site built homes there is a single return

located in the main body, e.g. living room, dining

room, central hallway, of the house. Air returning

from individual rooms can be restricted by door

closure. There is often very little area provided

for return air from closable rooms; typically

this pathway is the undercut at the bottom of

the doors. When interior doors are closed, the

bedrooms become pressurized and the main body

of the house depressurizes. Figure

6 shows the pressure differential effect

of duct leakage and inadequate return air pathways.

House #10 shows a postive pressure because of

a disconnected main return air duct; that house

operates nearly 9 Pascals positive when the air

handler fan cycles on. The typical manufactured

home experiences supply only type leakage as the

return grill is normally located on the air handler

unit.

Exhaust

fans (8% of the

homes investigated)

Negative

pressures can also be created by the use of exhaust

fans. Whole house ventilation fans installed

in HUD code housing are designed to be able to

continuously exhaust air from the house at a rate

of at least 0.035 cubic feet per minute per square

foot of interior floor space. These fans are

operated by manually switching them on or off

(24 CFR Part 3280.103). In our inspections, we

noted only one home where the factory installed

ventilation fan ran continuously – and it

suffered moisture problems (house #4). Typically,

this fan is not operated because of the noise

that it creates. Another case (house #16) we

investigated involved the installation of a dual

fan window unit. The owners converted a bedroom

into a pet care room and operated the window fans

to control odor. Unfortunately, this not only

removed the pet odor, but also depressurized the

entire house by 1 Pascal. High dewpoint crawlspace

air was pulled into the floor assembly through

numerous penetrations in the belly board and entered

the home via the plumbing, electrical and other

penetrations that existed in the floor. The result

was mold growth in the bathroom cabinets and the

deterioration of the subfloor under the kitchen

vinyl.

Inadequate

moisture removal (~80% of the homes investigated)

Proper

sizing, operation and maintenance of the air conditioning

system is necessary to maintain interior temperatures

and provide humidity control. It appears that

there may be a fair degree of oversizing of equipment,

though not specifically analyzed. Houses #19

and #20 are the same size, model, manufactured

in the same plant and are located a short distance

apart, yet one has a 4-ton air conditioning system

and the other only a 2.5 ton. Both experienced

problems, however the one with the larger unit

had a more severe moisture problem. Based on

the comments of the homeowners, some of the units

have the ability to lower interior temperatures

as much as 30 degrees below the ambient exterior

temperature. Anecdotally, we may say that if

the unit is capable of such a temperature difference,

then the unit is probably oversized. An oversized

unit will tend to short cycle, lowering the interior

temperatures, but not able to adequately remove

moisture from the air. In an effort to be comfortable,

the thermostat setting is lowered.

Excessive

duct system leakage also prevented adequate moisture

removal from the house. The air conditioning

systems were overwhelmed with ambient humidity

conditions. Three houses that were investigated,

had a portion of the duct system that was completely

disconnected. One (house #9) had a return duct

that had failed and was pulling the majority of

it’s air from the crawlspace. A second one

(house #3) experienced a disconnected crossover

supply duct. The majority of the conditioned

air was lost to the attic space. The third home

(house #16) had had the supply duct connecting

the package air condition system to the house

fall off at least three times within the first

few months after being installed.

Maintenance

and operation of the equipment also impacted the

moisture levels within the home. The thermostat

of house #4 was not operating correctly and the

air handler fan was always on. Operation of the

blower with supply leakage and door closure continuously

placed the home in a negative pressure of -1.0

Pascal. The home had had the interior wallboard

of all exterior walls replaced within the first

year of occupancy due to moisture damage. The

repair crew could not find the cause of the problem,

so the damaged wall was replaced, only to fail

again.

Blockage

in condensate drain line appears to have been

the final element needed to cause catastrophic

floor and wall damage to house #11. The homeowner

reported that the house had operated adequately

for the first year. They reportedly kept the

thermostat between 78-80oF and were

fairly comfortable. All at once the home felt

uncomfortable and the thermostat setting was lowered

to compensate, failure of materials and mold growth

soon followed. During our investigation, a pie

tin and plastic wrapper was found in the drain

pan of the evaporator coil of the unitary system.

The plastic wrapper was effectively blocking the

condensate drain line causing flooding of the

cabinet and recycling of the water back to the

house.

Moisture

diffusion through floor assembly (100% of the homes investigated)

It

appears in these homes inspected that one of the

moisture diffusion pathways existed between the

earth and floor coverings. The typical barrier

between the earth and floor coverings on a manufactured

home is a “belly board”. When these

belly boards have numerous penetrations or holes,

free passage of both air and water vapor into

the floor cavity now become an issue of concern.

In many cases, standing water, or evidence thereof,

existed in the crawlspaces below the belly boards.

A skirting that is designed to hide the crawlspaces

and provide attractive appearances then surrounds

these high moisture sources. [Note: a standard

for skirting ventilation of the area under the

home is to provide openings that have a net area

of at least one square foot for each 150 square

feet (Fleetwood Homes (1999) & Palm Harbor

Homes (2000)) [1] ]. Leaving warm, moist air no

choice but to rise up through the tears and other

openings of the belly boards into the subfloorings.

(This may be the result of air transported moisture

or moisture vapor diffusion or both.) The subfloorings,

composed of either plywood or wood composite materials,

allow moisture vapor to pass through to the floor

coverings. Carpeted surfaces offered little resistance

and moisture passes into the home; vinyl floor

coverings, on the other hand, are impermeable

surfaces and prevent moisture intrusion. If that

surface is at or below the dewpoint temperature

of the crawlspace air, then condensation occurs

on the underside of the impermeable flooring creating

favorable environments for mold growth.

There

appears to be a pattern of floor moisture/staining

problems when the duct system is located overhead

in the attic. Staining and warping of vinyl-covered

floors has occurred in areas under the register.

The areas of the vinyl covered flooring showing

the worst staining were being washed by cold air

from the supply registers (figure 7

& 8). Though measurements

were not made of floor temperatures, it stands

to reason that areas being washed by the supply

air will tend to be cooler than those areas not

washed. This cooling of the surfaces creates

temperatures below the crawlspace dewpoint temperature

and condensation occurs.

Vapor

retarder in the wrong location (100% of the homes investigated)

The

homes inspected followed the HUD code ruling on

moisture vapor control as defined by section 504,

which states…

3280.504 Condensation control

and installation of vapor retarders.

(a)

Ceiling vapor retarders. (1) In Uo

Value Zones 2 and 3, ceilings shall have a vapor

retarder with a permanence of not greater than

1 perm (as measured by ASTM E-96-93 Standard

Test Methods for Water Vapor Transmission of

Materials) installed on the living space side

of the roof cavity. (2) For manufactured homes

designed for Uo Value Zone 1, the vapor retarder

may be omitted.

(b)

Exterior walls. (1) Exterior walls shall

have a vapor barrier not greater than 1 perm

(dry cup method) installed on the living space

side of the wall, or (2) Unventilated wall cavities

shall have an external covering and/or sheathing

which forms the pressure envelope. The covering

and/or sheathing shall have a combined permeance

of not less than 5.0 perms….

(Note:

Uo Zone 1 includes Texas, Louisiana, Mississippi,

Alabama, Georgia, South Carolina, and Florida.)

It

is common practice for the manufacturers to use

a vinyl covered wallboard as the interior finished

surface. This is one of the most economical finishes

that can be applied and meets the vapor barrier

requirement. Testing of the wallboard with the

vinyl finish has been completed by others according

to the ASTM E-96 standard . The results of the

test showed that a 3/8” gypsum wall board

laminated with 4-mil vinyl has a perm rating of

0.42 (gr./hr.-ft3-in. Hg) (Manufactured

Housing Research Alliance 2000).

All

of the homes inspected that experienced wall board

failure were vinyl coated. Typical symptoms included

staining of the vinyl wallcoverings and bowing

of the wallboards. Additionally, negative air

pressures within the buildings were created by

duct leakages, door closures or a combination

of both.

The

vinyl floor coverings also fall into this category.

The vapor retarder is located on the interior

surface. The difference is that the problem has

only been seen in houses with overhead duct systems.

It is believed (testing to verify is still ongoing)

that the cool air from the supply registers is

being blown down to the floor and is cooling the

surfaces below outside air dewpoints. At this

point, the solution has been to replace the current

uni-directional registers with a multi-directional

one. Additionally, the belly board is also sealed

to prevent crawlspace vapor intrusion.

FIELD

TESTING

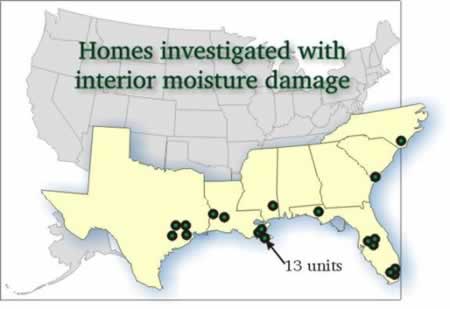

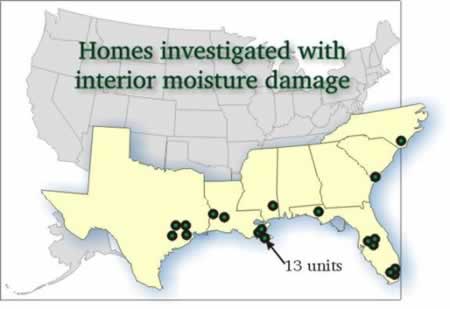

Currently,

more than 25 homes with moisture problems have

been field tested by BAIHP researchers and were

accompanied by the various manufacturer’s

service managers and other interested parties.

Table 1 provides observed and measured data from

several homes. The homes investigated are generally

located within 25 miles of the Atlantic Ocean

or Gulf of Mexico, ranging from North Carolina

to Texas (figure 9).

All of the homes have had at least one extensive

changeout of moisture damaged building materials,

many have had two or three.

Testing

Equipment and Procedures

FSEC’s

testing protocol employs a battery of tests to

establish the integrity of the building envelope

and the duct system. These tests assist in the

determination of the potential for air transported

moisture problems that can cause severe damage

to building components, increase energy consumption

and decrease occupant comfort. Ideally, the protocol

begins with three tests using a calibrated blower

door and a calibrated duct tester.

The

first test employs the calibrated blower door

and establishes a leakage rate for the house at

a specific pressure differential. This is usually

expressed in cubic feet per minute at 50 Pascals

(CFM50) or air changes per hour at 50 Pascals

(ACH50). The next two tests establish duct system

airtightness. These tests use the duct tester

and yield the leakage rate of the duct system

in a similar manner to the building air-tightness

test and are expressed in cubic feet per minute

at 25 Pascals (CFM25). One test measures the

total leakage from the duct system to the interior

and exterior of the building (CFM25total)

by pressurizing the duct system to 25 Pascals.

The second test measures leakage to the exterior

of the building only (CFM25out) by

pressurizing the building and the duct system

to the same pressure, removing any driving force

for leakage between the building and the duct

system. This results in the remaining leakage

being to the outside of the building envelope.

The results are airflow at 25 Pascals (cfm @ 25

Pa) and air leakage at 25 Pa normalized by the

conditioned house square footage (cfm/ft2 @ 25

Pa). A duct system to be considered to be “essentially

leak free” in the BIAHP project when the

normalized duct leakage to the outside is less

than 0.03 cfm/ft2 and the normalized total duct

leakage is less than 0.06 cfm/ft2.

[2]

The

testing protocol continued with a series of pressure

differential measurements across the building

envelope and across various zones within the building

as defined by interior doors. A digital micromanometer

with a resolution of 0.1 Pascal was used in all

of the pressure differential measurements. Pressure

differences may be created by either normal operation

of the building’s heating and cooling equipment,

ventilation system or exhaust fan (including clothes

dryers). Measurements were completed to determine

a magnitude and direction of flow across the envelope

when the various fans operate. Interior door

closure effect was also measured when the air

handler fan operated. Ideally, the pressure differentials

created across the building envelope and bedroom

doors should be fairly close to neutral.

Results

of Field Investigation

Since

the beginning of the moisture investigations in

the BAIHP project, it was the desire of this team

to try and determine the commonality that may

have existed. It appears that there is a common

thread that links moisture related failures and

the HUD code house of today.

There

are a number of similarities that existed in the

buildings that we inspected for the four manufacturer

team members:

All located in Southeast and

generally located within thirty miles of a large

body of water, either the Atlantic Ocean or

the Gulf of Mexico.

All had a forced air distribution

system that would generally considered to be

oversized. Most had duct leakage that was significant

and caused the building to operate in a negative

pressure.

Most of the homeowners kept the

thermostat setting between 68 and 75 degrees

F in an effort to maintain comfort.

Either a vinyl wallcovering or

a vinyl floor product was associated with the

moisture problem.

All of the homes have had at

least one major retrofit to repair the damaged

areas. Since a cause of the problem was not

located, the replaced materials were the same

as those that were removed.

Ventilation systems were usually

not used or disabled.

Typically, the master bedroom

door was closed for extended periods of time.

Usually, other bedroom doors were also closed

– especially at night if children were

present.

The belly board (vapor retarder)

contained numerous holes, penetrations and tears.

The typical repair or seal was with the use

of an adhesive backed cloth tape (duct tape)

which had failed.

Table

1 identifies some of the characteristics

of the homes and symptoms observed. In general,

the investigation team was dealing with a homeowner

that has a problem, sometimes severe, and data

was gathered to identify the cause or source of

the problem. This limited time at the house caused

the focus to be on solutions and not necessarily

research, though an effort was exerted to have

a common data collection protocol.

SUMMARY

AND DISCUSSION

The

BAIHP investigation team was usually called out

to homes that were not able to be solved by the

normal channels that existed through the manufacturers’

service departments. All of the problems that

were encountered related to moisture flow in a

vapor state. The causes of failure varied slightly

from house to house, but in general could be catorigized

as a result of any or all of the following:

manufacturing design and/or techniques

set-up and installation of non-factory

items such as air conditioning and

homeowner operation and maintainence

It

appears that moisture damage to the building materials

was a result of poor design criteria and workmanship

of a building that is located in a hot and humid

climate. There were some symptoms that were common

in cases:

Lowered air conditioner thermostat

setting (typically 68-73oF), well

below the ambient dew point.

Negative pressures across the

envelope from high supply duct leakage (cfm

@25Pa > 10 per 100 square feet of conditioned

floor area), inadequate return air paths, interior

door closures, exhaust fans or a combination

thereof.

Inadequate moisture removal from

disconnected return ducts, continuous operation

of air handler or exhaust fans, inadequate removal

of condensate, oversized air conditioner, poorly

maintained equipment or a combination thereof.

Moisture diffusion from the ground

into the house because of poor site drainage,

inadequate crawl space ventilation, tears in

the belly board, or a combination thereof.

Vapor retarder in the wrong location

i.e. vinyl or other impermeable wall or floor

coverings.

Recommended

solutions provided to the manufacturers to eliminate

moisture problems include:

Maintain air conditioner thermostat

above the ambient dew point (at least 75oF

)

Eliminate long term negative

pressures created by air handler fans or ventilation

equipment.

Tightly seal all ductwork and

provide adequate return air pathways.

Enhance moisture removal from

the conditioned space by correct sizing and

maintainence of equipment

Eliminate ground source water

and provide adequate moisture barrier for the

floor assembly

If possible, remove vapor barriers

located on the wrong surfaces.

One

of our manufacturing team members has been working

for the last five years in incorporting the best

practice designs and techniques into their product.

The result is that last year they reported no

moisture vapor related failures for the first

time in several years.

Work

is continuing to determine if these steps will

be sufficient to prevent problems even in the

presence of vapor barriers in the wrong locations

for the hot, humid climates that are preferred

by manufacturers and customers. There is still

much to done in the area of moisture research

as it relates to the interactions of buildings

and its mechanical systems. Negative pressures

created by mechanical systems within buildings

is sometimes difficult at best to correct. Obviously,

tight, well constructed duct systems with adequate

return air pathways is a giant step in the right

direction. There are still issues with ventilation,

especially exhaust only ventilation in the hot

and humid climates. Currently the HUD code does

not address the type of ventilation, only that

it must exist. Clothes dryers are another mechanical

exhaust device that exists in a great number of

homes. What is the effect of long term operation

in a home where it may operate three to six hours

per day? The industry, especially the HUD code

manufacturing industry is slow to change –

change costs money. They are looking for ways

to lower manufacturing costs and still provide

affordable housing.

Education.

HUD code manufacturers, suppliers, retailers,

setup crews, and various code officials struggle

with moisture related problems, especially those

problems caused by moisture in the vapor form.

Good, simple and to the point training materials

and courses are needed to assist in the design,

construction, operation and diagnostics as it

relates to moisture and moisture movement mechanisms.

The

Building America Industrialized Housing Partnership

will continue working with manufacturers, suppliers

and building officials in an effort to provide

research, training and support.

TABLES

Table

1 Collected Data From 25 HUD Code Homes With Moisture

Related Problems

FIGURES

Figure

1 - Finished ceiling assembly being transferred

to the house. This assembly will be fastened to

the exterior walls with screws. At this point,

the floors, plumbing, duct system and electrical

wiring rough-ins are complete

Figure

2

- A finished house in the function test area.

The plumbing and electrical systems are tested,

final touch-ups are completed and the home is

readied for transport.

Figure

3 -

A finished metal inline duct

system. Insulation on the ductwork may or may

not be installed, depending on final destination

of the home. This floor is currently being lowered

onto the chassis

Figure

4

This home is experiencing

a buckled floor problem. The subfloor is a HUD

code approved composite wood product that has

taken on moisture from the crawlspace.

Figure

5 A typical manufactured house with an inline

floor supply system loses 10-30% of the air to

the "belly" of the home. There are usually

numerous holes, penetrations and tears in the

"belly" board, which allows free air

movement between the crawlspace and the "belly".

The loss of the supply air tends to depressurize

the living space above.

Figure

6

Pressure differential measured across the front

door when the air handler fan is operating and

all of the interior bedroom doors are open and

then closed. The main body or area containing

the central return experiences a negative pressure

with reference to outside.

Figure

7 Breakfast nook with a vinyl floor covering and

overhead supply register. Visible discoloration

of the floor (pink spots) existed primarily in

the area between the table and the cabinets on

the right side of the picture. The supply register

was oriented as to blow air to the outside wall.

Figure

8 The floor covering has been partial removed.

The plywood flooring was wet to the touch and

staining exists on much of the under side of the

vinyl. The floor decking was removed to inspect

the underside – it appeared dry.

Figure

9 The southeastern portion of the United States

is considered to be a hot and humid climate.

The investigations that the BAIHP team has completed

are indicated. Note that most are near coastal

areas.

REFERENCES

Manufactured

Housing Institute (2000a), “Quick Facts,

The latest Trends in Manufactured Housing 2000-2001”,

2101 Wilson Blvd. Suite 610 • Arlington,

VA 22201–3062

Odom,

J.D. and DuBose, G., (1996) Preventing Indoor

Air Quality Problems in Hot, Humid Climates: Problem

Avoidance Guidelines, CH2M Hill, Orlando

24

CFR Part 3280, DEPARTMENT OF HOUSING AND URBAN

DEVELOPMENT [Docket No. FR-4376-P-01] Manufactured

Home Construction and Safety Standards

Fanger,

P.O. (1972), Thermal Comfort, McGraw-Hill, New

York, USA

Karg,

R. and Krigger J. (2000), Specification of Energy-Efficient

Installation and Maintenance Practices for Residential

HVAC Systems, Consortium for Energy Efficiency,One

State Street, Suite 1400, Boston, MA 02109-3507

Fleetwood

Homes (1999), “Installation Manual, Multi

Section, Wind Zone II & III”, Fleetwood

Enterprises Inc., PO Box 76387638, Riverside,

CA 92513-9953

Palm

Harbor Homes (2000), “Installation Manual”,

Palm Harbor Homes Inc., 15303

Dallas Parkway, Suite 800, Addison, TX 75001

Manufactured

Housing Research Alliance (2000), “Manufactured

Housing Technologies”, Volume 2 Issue 2,

2109 Broadway, Suite 200, New York, NY 10023

|