| |

|

| |

| Reference

Publication:

Chandra, Subrato, Neil Moyer, Danny Parker, David Beal,

David Chasar, Eric Martin, Janet McIlvaine, Ross McCluney,

Andrew Gordon, Mike Lubliner, Mike McSorley, Ken Fonorow,

Mike Mullens, Mark McGinley, Stephanie Hutchinson, David

Hoak, and Linda Tozer. Building America Industrialized

Housing Partnership, Annual Report - Fourth Budget Period.

04/01/03-03/31/04. |

|

|

| Building

America Industrialized Housing Partnership, Annual

Report - Fourth Budget Period |

|

|

Subrato

Chandra, Neil

Moyer, Danny

Parker, David

Beal, David

Chasar, Eric

Martin, Janet

McIlvaine, Ross

McCluney, Andrew

Gordon, Mike

Lubliner, Mike McSorley, Ken

Fonorow, Mike

Mullens, Mark

McGinley, Stephanie

Hutchinson, David

Hoak, and Linda Tozer |

|

| Florida

Solar Energy Center |

|

| |

|

Building

America Industrialized Housing Partnership (BAIHP)

TRIP

REPORT

Southern

Mississippi

Problem

Home Inspection, Testing and Possible Solutions

DATE

August

9, 2001

PURPOSE

- Assist

service and engineering staff in determining the

source or probable cause of moisture-related problems

and aid in repairs.

- Provide

confirmation, if possible, that moisture related

problems would not reappear.

INTRODUCTION

- Moisture

problems included some discoloring of wallboard and

staining of ceiling trim at various transitions. Also, a

section of wallboard near the front door had deteriorated

from water intrusion.

- Previously

damaged wallboard had been replaced once already

by service personnel. Repairs included replacing

with damage drywall with a similar product, repairing

supply duct system leakage and sealing wall-ceiling

penetrations.

DESCRIPTION

- 3

bedroom-2 bath 1330 ft2 singlewide with

fireplace.

- Open

crawlspace without skirting

- 3 ½ ton

split system AC and electric strip heat furnace

with an in-line metal floor duct system with metal

risers.

OBSERVATIONS

- Thermostat

was set at 75F

- Repairs

previously made included wallboard replacement, duct

sealing (with mastic), and sealing of various ceiling

transitions.

- Blend-Air

II ventilation system installed. The attic ventilation

fan had been disconnected.

- Homeowner

reported that the electric bill for the summer decreased

by $40 after the repairs were made.

- All

bedroom doors usually closed at night and open during

the day.

- Occupants

include 2 adults, 2 teenagers and 4 pets (2-cats and

2 dogs).

TESTING

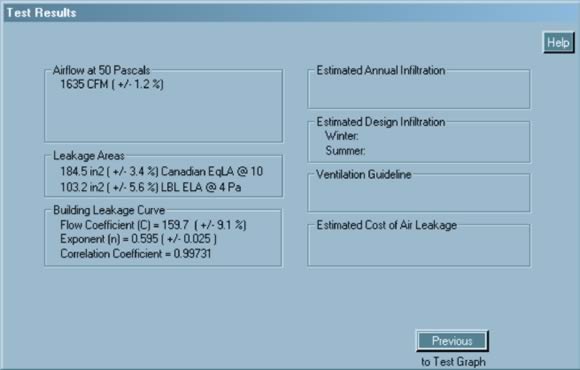

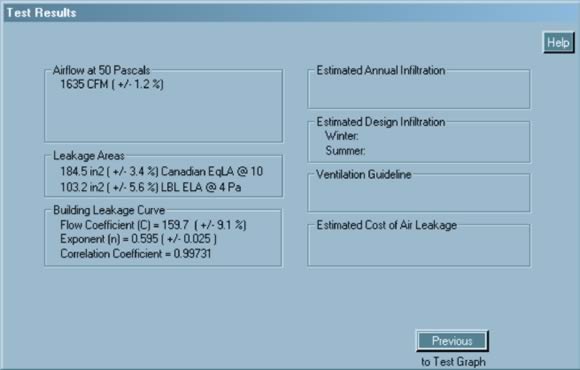

Blower

door test

A

blower door test was done to determine the airtightness

of the building envelope. A series of building

pressures and associated airflows was recorded. This

provides the necessary inputs to determine the CFM50

of the house. As a general rule of thumb, typical

values of building airtightness range between 0.75 and

1 CFM50 per square foot of conditioned floor area. This

house has a floor area of 1216 ft2 and a CFM50

of 1855 or 0.7 CFM50 per square foot – a tighter

home.

Blower

Door Test –As Found

CFM50

= 1855

[C=163.1,

n=0.62, r=0.99] |

The

values of C and n can be used as inputs for the house

airflow equation, Q=C* pn. Thus, for

any given pressure difference, P, the airflow crossing

the building’s envelope can be determined.

Duct

test

A

duct system airtightness test was also completed. A

duct tester was attached to the air handler unit. The

supply registers were temporarily sealed off and the

system was then depressurized to 25 pascals. The

total and outside leakage flow components were measured. An

airtight duct system would have zero leakage or both

the CFM25total and CFM25out would

be 0.

Duct

System Airtightness |

CFM25total =

47

CFM25out =

32 |

Pressure

diagnostic testing

Pressure

differential measurements were completed to determine

a magnitude and direction of flow across the envelope

when the air handler fan operates. Interior door

closure effect was also measured when the air handler

fan operated.

Pressure

Diagnostics w/ AHU

(Note:

the winds were calm) |

Condition |

Pressure

differential (main wrt outside) |

All

fans off |

0

pa |

AHU

on |

-1.6

pa |

AHU

on & master suite door closed |

-10.7

pa |

AHU

on & all interior doors closed |

-13.0

pa |

The

pressure difference was also measured across each closed

door when the air handler fan was operating (all supply

registers were open and exhaust was off).

Pressure

across closed doors |

Pressure

differential (room wrt main) |

Master

bedroom |

24.5

pa |

Center

Bedroom |

3.9

pa |

End

Bedroom |

6.6

pa |

EFFECTS

- Return

air path to AHU is hindered when bedroom doors are

closed – especially

the master suite door.

- Flow

imbalances cause the master bedroom to be overcooled

before the other bedrooms are cooled. This overcooling

causes the exterior vinyl covered walls to drop to the

ambient air dewpoint temperature or below.

- Duct

leakage, on the supply side, causes the entire building

to operate at a negative pressure. Any pathway

from the exterior to the interior – such as electrical

penetrations- provides a pathway for ambient air to reach

interior surfaces. One such area is at the light

fixture mounted on the wall of the master bath.

RECOMMENDATIONS

- Keep

thermostat set at 78 F or above.

- The

flow imbalances (especially the excessive air in

the master suite) should be corrected.

- All

duct leaks should be repaired with mastic. The

supply plenum and all risers should be checked and repaired

as needed. The refrigerant line penetration through

the air handler cabinet should also be sealed. The

duct leakage should not exceed 3% of floor area or CFM25

less than 40.

- The

3-inch reducer in the supply plenum should be removed.

- A

separate return direct to the AHU is needed (through

the wall or jump duct) from the master suite.

- Sufficient

return air pathways should be installed in the rest

of the bedrooms.

- All

belly penetrations should be sealed with a permanent,

long-lasting seal. No duct tape.

- In

general, vinyl covered exterior drywall should not

be used in hot and humid climates.

PICTURES

|

|

Front

elevation |

Rear

elevation |

|

|

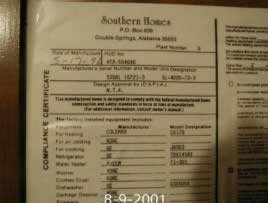

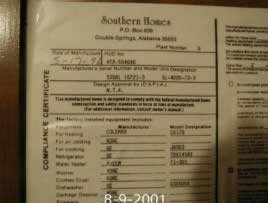

Compliance

sticker |

Blower

door assembly |

|

|

Duct

tester attached to furnace |

Thermostat |

|

|

Outside

air duct to furnace top |

Furnace

fan removed to inspect plenum |

|

|

Electric

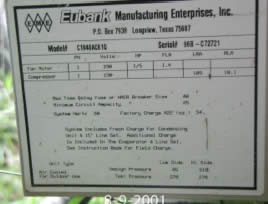

furnace with 3-row AC coil |

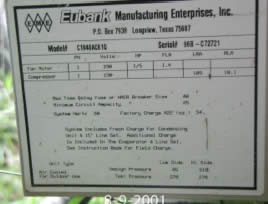

AC

nameplate |

|

|

Ceiling

transition repair being made |

Inspecting

wall moisture content |

|

|

AC

condensate draining on pier and ponding |

Eroded

pier support under hall bath |

|

Close-up eroded

pier support |

|

Disclaimer:

This report was prepared as an account of work sponsored by an agency

of the United States government. Neither the United States government

nor any agency thereof, nor any of their employees, makes any

warranty, express or implied, or assumes any legal liability

or responsibility for the accuracy, completeness, or usefulness

of any information, apparatus, product, or process disclosed,

or represents that its use would not infringe privately owned

rights. Reference herein to any specific commercial product,

process, or service by trade name, trademark, manufacturer,

or otherwise does not necessarily constitute or imply its endorsement,

recommendation, or favoring by the United States government

or any agency thereof. The views and opinions of authors expressed

herein do not necessarily state or reflect those of the United

States government or any agency thereof.

|