- Reflective Roofing Research

|

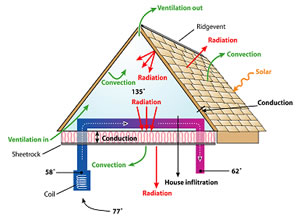

Figure 72 Vented attic thermal processes. |

Improving

attic thermal performance is fundamental to controlling residential

cooling loads in hot climates. Research shows that the influence

of attics on space cooling is not only due to the change

in ceiling heat flux, but often due to the conditions within

the attic, and their influence on duct system heat gain and

building air infiltration. (Figure 72)

The importance of ceiling heat flux has long been recognized,

with insulation a proven means of controlling excessive gains.

However when ducts are present in the attic, the magnitude

of heat gain to the thermal distribution system can be much

greater than the ceiling heat flux. This influence may be

exacerbated by the location of the air handler within the

attic space - a common practice in much of the southern US.

Typically an air handler is poorly insulated and has the

greatest temperature difference at the evaporator of any

location in the cooling system. It also has the greatest

negative pressure just before the fan so that some leakage

into the unit is inevitable.

The Flexible Roof Facility (FRF) is an FSEC test facility

designed to evaluate five roofing systems at a time against

a control roof with black shingles and vented attic (Figure

73).

5th

Budget Period Experiments

The testing evaluates how roofing systems impact summer

residential cooling energy use and peak demand. In the summer

of 2003, the roofing systems tested are listed in Table

45. Cell numbering is from left to right beginning with

the second cell in from the left.

Table

45 Roofing systems tested at the FSEC

Flexible Roofing

Facility, Summer of 2003 |

Cell # |

Description |

1 |

Galvalume®*

unfinished 5-vee metal with vented attic (2 nd year

of exposure) |

2 |

Sealed attic with proprietary

configuration |

3 |

High reflectance brown

metal shingle with vented attic |

4 |

Galvanized unfinished

5-vee metal with vented attic (2 nd year of exposure) |

5 |

Black shingles with standard

attic ventilation (Control Test Cell) |

6 |

standing seam metal with

vented attic (2 nd year of exposure after cleaning) |

* Galvalume

is a quality cold-rolled sheet to which is applied

a highly corrosion-resistant hot-dip metallic coating

consisting of 55% aluminum 43.4% zinc, and 1.6% silicon,

nominal percentages by weight. This results in a

sheet that offers the best protective features characteristic

of aluminum and zinc: the barrier protection and

long life of aluminum and the sacrificial or galvanic

protection of zinc at cut or sheared edges. According

to Bethlehem Steel, twenty-four years of actual outdoor

exposure tests in a variety of atmospheric environments

demonstrate that bare Galvalume sheet exhibits superior

corrosion-resistance properties. |

|

Figure 73 Flexible

Roof Facility

in summer of 2003 configuration. |

All had R-19 insulation installed on the attic floor except

in the configuration with the sealed attic (Cell #2) which

had R-19 of open cell foam sprayed onto the bottom of the

roof decking. The measured thermal impacts include ceiling

heat flux, unintended attic air leakage and duct heat gain.

Cell

#2 had a proprietary configuration which is not reported

upon in this report.

A

major thrust of the testing for 2003 was comparative testing

of metal roofing under long term exposure. Given the popularity

of unfinished metal roofs, we tested both galvanized and

Galvalume® roofs in their second year

of exposure. Galvalume® roofs are reported to better

maintain their higher solar reflectance than galvanized types.

Average daily mid-attic maximum temperatures for the Galvalume® and

galvanized metal roof systems showed significantly better

performance for Galvalume® product (17.5 oF and 13.1

oF cooler than the control dark shingle respectively).

|

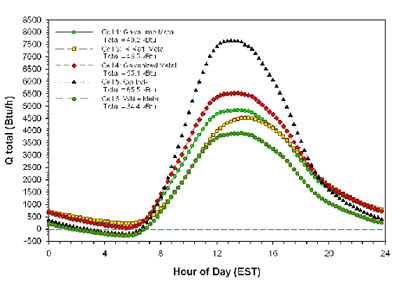

Figure

74 Estimated combined

impact of duct heat

gain,air leakage from the attic

to conditioned space

and ceiling heat flux on space

cooling needs on an

average summer day in a 2,000

ft 2 home. |

Other

than the sealed attic case, the white metal roof results

in the coolest attic over the summer, with an average peak

of only 94.6 oF – 22.1 o cooler than the peak

in the control attic with dark shingles. The highly reflective

brown metal shingle roof (Cell #3) provided the next coolest

peak attic temperature. Its average maximum daily mid-attic

temperature was 101.5 oF (15.2 oF lower than the control

dark shingle cell). While the brown metal shingle roof’s

reflectance was lower than the two metal roofs and white

metal roof we observed evidence that the air space under

the metal shingles provides additional effective thermal

insulation.

We

also estimated the combined impact of ceiling heat flux,

duct heat gain and unintended attic air leakage from the

various roof constructions. All of the alternative constructions

produced lower estimated cooling energy loads than the standard

vented attic with dark shingles (Figure 74). The

Galvalume® roof clearly provided greater reductions to

cooling energy use than the galvanized roof after two summers

of exposure.

One

important fact from our testing is that nighttime attic

temperature and reverse ceiling heat flux have a significant

impact on the total daily heat gain, particularly for the

metal roofs. The rank order in Table 46 shows the percentage

reduction of roof/attic related heat gain and approximate

overall building cooling energy savings (which reflect

the overall contribution of the roof/attic to total cooling

needs):

Table 46

Roof cooling load reduction and overall

cooling savings,

Summer 2003 experiments |

Rank |

Description |

Roof

Cooling Load Reduction |

Overall

Cooling Savings |

1 |

White metal with vented

attic (Cell #6) |

47% |

15% |

2 |

High reflectance brown

metal shingle with vented attic (Cell #3) |

29% |

10% |

3 |

Galvalume® unfinished

metal with vented attic (Cell #1) |

25% |

8% |

4 |

Galvanized unfinished metal

roof with vented attic (Cell #4) |

16% |

5% |

The relative reductions are consistent with the whole-house

testing recently completed for FPL in Ft. Myers (Parker et

al., 2001). This testing showed white metal roofing having

the largest reductions, followed by darker constructions.

4th

Budget Period Experiments

|

Figure 75 Flexible Roof

Facility in

summer 2002 configuration. Cells are numbered

from left to right starting

with the second cell in

from the left. |

The

Flexible Roof Facility (FRF), located in Cocoa, Florida,

is designed to simultaneously evaluate five roofing systems

against a control roof with black shingles and vented attic. (Figure

75) The test evaluated how roofing systems impact summer

residential cooling energy use and peak demand. In the summer

of 2002, six roofing systems were evaluated as described

in Table 47.

Table

47 Roofing systems tested and associated energy

savings

at the

FSEC Flexible Roofing Facility, Summer of 2002

|

Cell # |

Roof Material |

Ventilation

|

Roof Cooling Load

Reduction |

Overall Cooling

Savings |

#1 |

Galvalume® unfinished

5-vee metal |

vented |

32% |

11% |

#2 |

double roof with radiant

barrier (ins roof deck) |

sealed |

7% |

2% |

#3 |

high reflectance ivory

metal shingle |

vented |

38% |

12% |

#4 |

galvanized unfinished

5-vee metal |

vented |

22% |

7% |

#5 |

black shingles (control

cell) |

vented |

control |

control |

#6 |

white standing seam metal |

vented |

7% |

2% |

All roof cells had R-19 insulation installed on the attic

floor, except the double roof configuration (Cell #2) which

had a level of R-19 open cell foam sprayed onto the bottom

of the roof decking. Measured thermal impacts included ceiling

heat flux, unintended attic air leakage, and duct heat gain.

The sealed attic double roof system (Cell #2) provided

the coolest attic space of all systems tested (average maximum

mid-attic temperature was 81.1 oF), and therefore had the

lowest estimated impact due to return air leakage and duct

conduction heat gains. However this cell also had the highest

ceiling heat flux of all strategies tested, and recorded

the most modest space cooling reduction (7%), relative to

the control roof.

Metal

roof testing was given more emphasis in 2002 due to the

popularity of these products. Researchers tested both galvanized

and Galvalume ® roofs. Galvalume is a cold-rolled

sheet with a highly corrosion-resistant hot-dip metallic

coating application of 55% aluminum 43.4% zinc, and 1.6%

silicon. These roofs are reported to better maintain solar

reflectance than galvanized roofing systems. Average daily

mid-attic maximum temperatures for the Galvalume ® and

galvanized metal roof systems were roughly similar (19.6

oF and 17.3 oF cooler than the control roof, respectively).

The estimated total heat gain for these roof cells also was

relatively close.

|

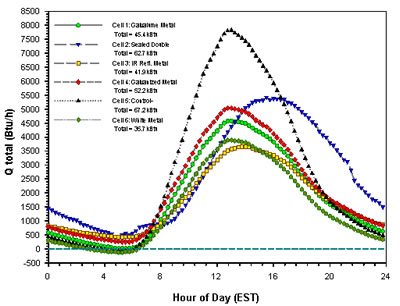

Figure 76 2002

estimated combined impact of duct heat

gain, air

leakage from the attic to conditioned space, and

ceiling heat flux on space cooling needs on an average |

The

highly reflective ivory metal shingle roof (Cell #3) provided

the coolest peak attic temperature of all the cells without

roof deck insulation. Its average maximum daily mid-attic

temperature was 93.3 oF (23.4 oF lower than the control

dark shingle cell). While the ivory metal shingle roof’s

reflectance was slightly lower than the two metal roofs and white metal roof,

researchers noted that the air space under the metal shingles provided additional

effective thermal insulation.

Researchers also estimated the combined impact of ceiling

heat flux, duct heat gain, and unintended attic air leakage

from the various roof constructions. All of the alternative

roofing treatments produced lower estimated cooling energy

loads than the standard vented attic with dark shingles. (Figure

76) The Galvalume® roof clearly provided a greater

cooling energy use reduction than the galvanized roof.

This also was true during the 2001 study. Nighttime attic

temperatures and reverse ceiling heat flux have a significant

impact on the total daily heat gain, particularly for metal

roofs.

3rd

Budget Period

|

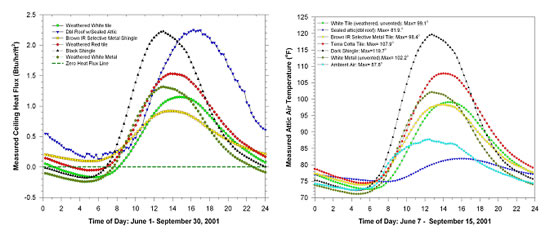

Figure 77 2001 Experimental

roof cell.

Cells are numbered from left to right

starting

with the cell second in from the left |

In

the 2001 testing, Cell #2 with the double roof/sealed attic

showed the lowest attic temperatures and narrowest temperature

range. (Table 48; Figures 77 and 79) Peak attic

temperatures in Cell #2 were 5 oF to 6 oF lower than this

same sealed cell the year before, without the double roof.

This indicates that the double roof did provide a substantial

benefit. Since there is no insulation on the attic floor

though, there still is a significant heat gain across the

ceiling. In fact, the ceiling heat fluctuation actually is

higher than the reference Cell #5. (Figure 78)

The true impact of the double roof construction of Cell

#2 is most likely a combination of the benefits of a cooler

attic space that reduces duct heat gain and minimizes the

effects of air leakage from the attic into the house, and

the drawback of the higher ceiling heat flux.

Cell #3 with its spectrally selective dark brown metal

shingles, produced lower attic temperatures at night, but

higher roof deck temperatures (which were most likely due

to the insulating quality of the shingles which have an air

space underneath them).

Table

48 Roofing systems tested and attic temperatures

at the FSEC Flexible Roofing

Facility, Summer of 2001

|

Cell # |

Roof Material |

Ventilation

|

Avg Attic Temp |

Max Attic Temp |

#1 |

white tile (weathered) |

sealed |

84.6 |

111.2 |

#2 |

double roof with radiant

barrier (ins roof deck) |

sealed |

78.4 |

85.4 |

#3 |

brown IR selective metal

shingle |

vented |

85.0 |

110.8 |

#4 |

terra cotta tile (weathered) |

vented |

89.0 |

124.3 |

#5 |

dark shingles (control) |

vented |

91.0 |

143.4 |

#6 |

white standing seam metal

(weathered) |

sealed |

84.0 |

115.5 |

Roofing

Experiment with Habitat for Humanity in Fort Myers, Florida

In July 2000, FSEC and Florida Power and Light instrumented

six side-by-side Habitat for Humanity homes in Ft. Myers

with identical floor plans, orientation, and ceiling insulation,

but with different roofing systems as described in Table

49. A seventh monitored house contained an unvented

attic with insulation on the underside of the roof deck rather

than on the ceiling.

Each unoccupied home was monitored from July 8 through July

31, 2001 to collect building thermal and air conditioning

power data. Table 50 presents the cooling performance

of the roofing systems clearly showing the energy-saving

benefits of reflective roofing systems in Florida, especially

the tile and metal roofs with solar reflectance between 65%

and 75%.

Table

49 Roofing systems tested at side-by-side

Habitat for Humanity homes

in Ft. Myers Summer of 2000

|

Code |

Description |

Code |

Description |

RGS |

Standard dark shingles

(control) |

RTB |

Terra

cotta "barrel" S-tile

roof |

RWS |

Light colored shingles |

RWB |

White "barrel" S-tile

roof |

RWM |

White metal roof |

RWF |

White flat tile roof |

RSL |

Standard

dark shingles with sealed attic & R-19 roof deck

insulation |

|

Table

50 Energy use and savings from roofing systems in

Habitat for Humanity roofing

study, summer of 2000

|

Site |

Total kWh |

Savings kWh |

Saved Percent |

Demand kW |

Savings kW |

Saved Percent |

RGS |

17.03 |

---- |

---- |

1.63 |

---- |

---- |

RWS |

15.29 |

1.74 |

10.2% |

1.44 |

0.19 |

11.80% |

RSL |

14.73 |

2.30 |

13.05% |

1.63 |

0.01 |

0.30% |

RTB |

16.02 |

1.01 |

5.9% |

1.57 |

0.06 |

3.70% |

RWB |

13.32 |

3.71 |

21.8% |

1.07 |

0.56 |

34.20% |

RWF |

13.20 |

3.83 |

22.5% |

1.02 |

0.61 |

37.50% |

RWM |

12.03 |

5.00 |

29.4% |

0.98 |

0.65 |

39.70% |

Significant findings: Reflective roofing materials represent

one of the most significant energy-saving options available

to homeowners and builders. These materials also reduce cooling

demand during utility coincident peak periods, and are potentially

one of the most effective methods for controlling demand.

- Based on comparative data from August of 2000, the maximum

decking temperatures in the sealed attic home were 23 E

F higher than the control home (177 E versus 154 E ). After

the installation of white shingles in midsummer, the highest

deck temperature from the sealed attic home measured only

7 E higher than the control in August of 2001 (161 E versus

154 E ).

- An

additional month’s data was

collected with the homes occupied and thermostat set

points kept constant. Average cooling energy use for

the homes rose by 36%, but there was no decrease in the

highly reflective roofing system savings. Additional

heat gained from the occupants and their appliance use

increased the cooling system runtime and introduced more

hot air into the air conditioning duct system.

- In 2001, the average maximum attic air temperature in

the terra cotta barrel tile roof home was 15 E F hotter

than the maximum ambient. After installing a radiant barrier

the average difference in August was +9 E F. A similar

evaluation with the light colored shingles showed that

peak attic air temperatures dropped from + 29 E to +20

E F after installing a radiant barrier.

- Household interior temperature settings varied from

one year to the next, making direct energy saving comparisons

impossible. Still, the collected data did show that attic

air temperatures were reduced by the radiant barrier. On

the other hand, measured maximum plywood decking temperatures

rose by 11 E to 13 E F.

- Based on previously evaluated roof buckling problems

on the decking of the sealed attic home, researchers decided

to install white shingles similar to those on the RWS roof.

It was thought that buckling problems likely were caused

by excessive heat buildup in this roofing system. White

shingles replaced the dark shingles to see if this would

drop the roof decking temperature spikes.

|

You

are here:

You

are here: