|

Scope

In effect since March 2003, Section 601.4 of the Florida

Building Code applies to residential and commercial buildings

having interior doors and one, centrally located return air

intake per heating and cooling system.

Objective Of The New Florida HVAC Code Requirement

Reduce

pressure difference in closed rooms with respect to (wrt)

the space where the central return is located to 0.01” water

column (wc) or 2.5 pascal (Pa) or less. Pressure imbalances

created by restricted return air flow from rooms isolated

from the central return by closed interior doors create

uncontrolled air flow patterns.

Technical

Background

|

Figure 80

Return

Air Flow Test Chamber |

Ideally, forced-air heating and cooling systems circulate

an equal volume of return air and supply air through the

conditioning system, keeping air pressure throughout the

building neutral. Each conditioned space in the building

should, ideally, be at neutral air pressure at all times.

When a space is under a positive air pressure, indoor air

will be pushed outward in the walls, floor and ceiling. When

a space is under a negative pressure, air will be pulled

inward through the walls, floor and ceiling. Negative and

positive air pressures in buildings result from uncontrolled

air flow patterns.

Section 601.4 of the Florida Building Code specifically

deals with the uncontrolled air flow pattern when interior

doors are closed thereby reducing return air flow from the

closed room, while maintaining the same supply air flow to

the room. This imbalance of supply and return air has been

addressed conventionally by the common practice of undercutting

interior doors to allow return air to flow from the room.

This research quantifies the volume of air flow provided

by this and other methods of return air egress from closed

rooms.

Section

601.4 limits the air pressure imbalance in closed rooms

to 0.01” wc or 2.5 pascals when compared to,

or with respect to (wrt), the main body of the building where

the return is located. With door undercuts, researchers have

regularly observed room pressures with respect to the main

body of the house (wrt mainbody) of +7 pascals (pa) or more.

A room with this level of air pressure (+7pa, wrt mainbody)

is trapping air, starving the heating/cooling system of return

air. As the heating/cooling system struggles to pull in the

designed amount of air, the resulting negative pressure pulls

air into the main body of the building along the path(es)

of least resistance. Usually this means that air is flowing

through the walls, floor and ceiling from unconditioned spaces

or outside environment to makeup for the trapped air in the

closed room.

In the closed room, positive pressure builds up when return

air is trapped. Conversely, the space with the central return

gets depressurized because extra return air is being removed

to make up for the air trapped in the closed room. More air

is leaving the space (return air) than is entering the space

(supply air). The positive pressure in the closed rooms pushes air

into unconditioned spaces, such as the attic and wall cavities.

The negative pressure in the main body of the building pulls air

from unconditioned spaces. In Florida, the air brings heat

and moisture with it that become an extra cooling load. This

air is referred to as “mechanically induced infiltration” since

the negative pressure drawing infiltration air in was created

by the mechanical system.

Styles of Pressure Relief

|

Figure 81 Installing

unbaffled

return air flow through wall grille |

|

Figure 82 Installing

sound baffled return air flow through wall insert

made by Tamarack. |

When

return air flow is restricted by closed doors, it creates

pressure differences between parts of the building. This

can be prevented by installing a fully ducted return system,

by creating a passive return air pathway such as a louvered

transoms, door undercut, “jump duct”, through-wall

grilles, or a baffled through-wall grill.

A “jump duct” is

simply a piece of flex duct attached to a ceiling register

in the closed room and another ceiling register in the

main body of the house. A jumper duct provides some noise

control while providing a clear air flow path.

A

through-wall grille is the simplest and least expensive approach

to pressure relief for closed rooms. Holes opposite each

other on either side of the wall within the same stud bay

are covered with a return air grilles. The

downside of this

approach is a severe compromise the privacy of the closed

room. An improvement on this theme would be to locate one

of the grilles high on the wall and the opposing opening

low on the wall. Also, such openings in interior wall cavities

introduce conditioned air into what is typically an unconditioned

space possibly contributing to other building problems.

However,

connecting the two openings with a sleeve of rigid ducting

forms an enclosed air flow path that limits introduction

of conditioned air into the wall cavity but doesn’t

solve the visual and sound privacy issues. To address this

problem, BAIHP Industry Partner Tamarack developed a sleeve

with a baffle that can reduce the transfer of light and sound

but still provide adequate air flow to minimize pressure

differences. The product is called a Return Air Path (RAP).

To

validate the effectiveness of this product and other approaches

to providing return air pathways, Tamarack and BAIHP researchers

devised a test apparatus and conducted experiments in FSEC’s

Building Science Laboratory.

Testing Protocol

In

May of 2003, a chamber was constructed at FSEC (Figure

80) that simulated a frame construction room with an

8 foot high ceiling. A “Minneapolis Duct Blaster” was

connected to one end of the room with a flexible duct connection

leading out of the room to provide control over pressure

in test chamber.

In

the middle of the chamber, on a stool, a radio was tuned “off

station” to effectively create a standardized level

of “white noise” at 57 dBA inside the chamber

with the “door” closed. The temperature at the

start of the tests was 80°F at 40%RH. A sound meter was

located outside the chamber on a stand 4 feet above the floor

and 20 inches from the middle of the chamber wall surface.

The

sound level in the test facility outside the chamber with

the “white noise” turned off was 36.4 dBA

and with the “white noise” turned on was 41.5

dBA, an average, sampled over a 30 second period. A series

of tests on 31 different set-ups were performed, measuring

the flow at 3 different pressure levels and recording a 30

second sound sample with the “Duct Blaster” deactivated.

Tests

were made for 6” and 8” jump ducts, five

different sized wall openings (Figure 81) in different

configurations including straight through with and without

sleeves, straight through with sleeve and privacy baffle (Figure

82), and high/low offset using the wall cavity as a

duct, and three different slots simulating three different

size undercut doors.

Results

Table 51 summarizes

the results of these tests arranged in ascending air flow

order based on the results at 2.5 Pascals (0.01” wc),

the maximum allowable pressure in a closed room under new

requirement in Florida Building Code, Section 601.4.

Table

51 Air Flow Resulting from Various Return Air

Path

Configurations at

Controlled Room Pressure

Difference (ΔP)with respect to Return Zone

|

Dim. |

Air

Flow (cfm) at |

Area |

Air

Flow to Area Ratio |

Return

Air Path Configuration |

Extra |

ΔP=1

pa |

ΔP=2.5 pa

|

ΔP=5

pa |

6 dia |

22 |

36 |

52 |

28 |

1.29 |

Jumper Duct |

|

4x12 |

26 |

41 |

60 |

48 |

0.85 |

Wall Cavity |

|

4x12 |

25 |

42 |

61 |

48 |

0.88 |

Wall Sleeve |

RAP Insert |

4x12 |

28 |

45 |

65 |

48 |

0.94 |

No Sleeve |

|

4x12 |

29 |

46 |

68 |

48 |

0.96 |

Wall Sleeve |

|

8x8 |

31 |

49 |

72 |

64 |

0.77 |

Wall Cavity |

|

12x6 |

32 |

52 |

75 |

72 |

0.72 |

Wall Cavity |

|

12x6 |

33 |

56 |

82 |

72 |

0.78 |

Wall Sleeve |

RAP Insert |

8x8 |

35 |

57 |

81 |

64 |

0.89 |

No Sleeve |

|

8x8 |

34 |

58 |

83 |

64 |

0.91 |

Wall Sleeve |

RAP Insert |

8x8 |

36 |

59 |

85 |

64 |

0.92 |

Wall Sleeve |

|

12x6 |

36 |

60 |

88 |

72 |

0.83 |

No Sleeve |

|

12x6 |

37 |

60 |

88 |

72 |

0.83 |

Wall Sleeve |

|

1 x 30 |

39 |

61 |

88 |

30 |

2.03 |

Slot |

|

8 dia |

38 |

62 |

90 |

50 |

1.24 |

Jumper Duct |

|

1 x 32 |

42 |

65 |

92 |

32 |

2.03 |

Slot |

|

8x8 |

40 |

67 |

95 |

64 |

1.05 |

Wall Cavity |

Two Inside Holes |

8x14 |

44 |

70 |

100 |

112 |

0.63 |

Wall Cavity |

|

12x12 |

45 |

72 |

103 |

144 |

0.50 |

Wall Cavity |

|

1 x 36 |

49 |

73 |

103 |

36 |

2.03 |

Slot |

|

8x14 |

61 |

101 |

146 |

112 |

0.90 |

Wall Sleeve |

RAP Insert |

8x14 |

68 |

107 |

153 |

112 |

0.96 |

No Sleeve |

|

8x14 |

68 |

110 |

154 |

112 |

0.98 |

Wall Sleeve |

|

12x12 |

75 |

119 |

170 |

144 |

0.83 |

No Sleeve |

|

12x12 |

74 |

120 |

169 |

144 |

0.83 |

Wall Sleeve |

|

12x12 |

74 |

120 |

174 |

144 |

0.83 |

Wall Sleeve |

RAP Insert |

|

Figure 83 Return air flow path

provided

by jumper duct

|

By

comparing the air flow of the slots (door undercut) to the

openings with grilles, the detrimental effect of the grille

becomes clear. The ratio of air flow (cfm) to the surface

area of the slot (in 2) is more than 2 to 1 (for example;

30 in 2 to 61 cfm), whereas with grilles in place the ratio

of air flow to area averages 0.83 to 1 (for example; 72 in

2 to 60 cfm). Similarly, the jump duct (Figure 83) assemblies’ air

flow to area ratios average 1.19 to 1. In any calculation

for the size of the through wall assembly, the resistance

of the grille becomes the critical factor in determining

the size of the opening for achieving the desired flow.

The following formulas account for the grille resistance

and maybe used to size return air path openings.

- Door undercuts: Area Sq. In. = CFM/2

- Wall opening with grilles: Area Sq. In. = CFM/.83

- Flexible

jumper duct with grilles: Diameter = ÖCFM

Although there does not appear to be significant flow improvement

when a sleeve is used, such an assembly will reduce the possibility

of inadvertent air flow from the wall cavity itself.

The high/low grilles using the wall cavity reach maximum

flow at 72 cfm because of the dimensional limitations of

the wall cavity itself. Increasing the opening of each grille

beyond 112 square inches does not significantly increase

the flow of air through the wall cavity.

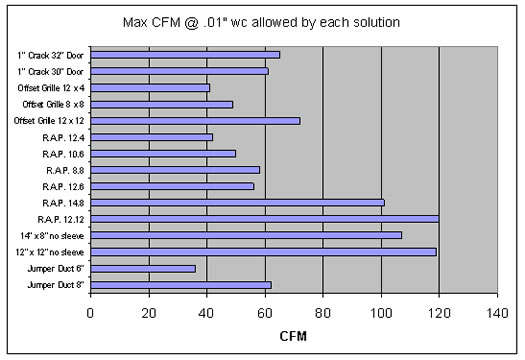

The accompanying bar chart (Figure 84) can

be used to select the best method at various air flows

while maintaining the room-to-building pressure difference

at .01” wc.

The strategies are ranked by air flow allowance (cfm) on

equivalent to supply air delivered to the room. For example,

an 8” jumper duct could be used to maintain 0.01 wc

in rooms with supply air up to 60 cfm. Note that these transfer

methods are additive so that, for example, combining a 6” transfer

duct with a 1” undercut a 30” door, will provide

a flow of 95 cfm to be delivered at .01” wc (Figure

85) or combining a R.A.P. 12.12 with a 1” undercut

would allow up to 175 cfm to be delivered (Figure 86).

It should be noted that door undercuts are under builder

not HVAC control and that the actual dimensions are greatly

affected by the thickness of the floor coverings.

Summary

Ideally buildings with forced air heating/cooling systems

are pressure neutral. The same amount of air is removed from

the building (and each room) as is supplied to it. However,

this balance can be disturbed in homes that have one, centrally

located return intake when interior doors are closed, blocking

return of air supplied to private rooms. Other factors outside

the scope of this study may also result in household pressure

imbalances.

These research results are relevant to homes with forced

air heating and cooling systems having a single, centrally

located return air inlet with no engineered path for return

air to exit closed rooms. Such systems pull return air from

the whole house as long as interior doors are open. When

an interior door is closed, more air is supplied to the closed

room than can be removed, or returned, from the room.

Positive

pressure builds up in the closed room while a negative

pressure occurs in the connected spaces. Positive pressure

presses outward on all surfaces and may eventually reduce

supply air flow into the closed room and while pushing

conditioned air through small breaks in the room’s

air barrier.

To overcome house pressure imbalances caused by door closure,

a variety of passive return path strategies are studied including

a product produced by BAIHP Industry Partner Tamarack that

overcomes privacy issues associated with through-wall grills.

Achievable air flows for jump ducts, through-wall grilles,

sleeved through-wall grilles, and the Tamarack baffled through-wall

grille are presented.

|

Figure 84 Maximum

air flow achievable using various return air paths

from closed rooms for a give supply at a room

pressure of 2.5 pa or 0.1”

wc with respect to the return

zone. For example, an 8” jumper duct could

be used to maintain 0.01 wc in rooms with supply

air up to 60 cfm. |

- Heat

Pump Water Heater Evaluation

|

Figure 87 Airflow

measurements

using a Duct tester on heat pump

cold

air discharge side |

BAIHP researcher tested the efficiency of a heat pump water

heater manufactured by EMI, a division of ECR International.

The unit features a compressor (R-134A refrigerant) with

a wrap-around heat exchanger mounted on top of a 50-gallon

storage tank. The latest controller board model #AK 4001

was installed during the test.

The

temperature regulation of the unit is achieved by an adjustable

potentiometer which sets a resistance that is measured

by the controller board and translated into the corresponding

temperatures. The set temperature is stored in the controller’s

memory.

The

controller logic is designed to operate

the heat pump when

the temperature in the bottom of the tank drops below the

effective dead band temperature of 30°F (20°F

deadband + assumed stratification of 10°F). The heat

pump shuts off when the temperature in the bottom of the

tank has reached 10°F below the set point temperature.

The upper element of the tank operates only when the temperature

in the upper tank reaches 27°F below the set point temperature.

During

laboratory testing the controller’s performance

was evaluated by measuring inlet and outlet water temperatures

using thermocouples mounted to the copper inlet and outlet

pipes as well as a Fluke hand-held thermometer inserted into

the hot water outlet stream. One minute average measurements

during draws were in agreement with the 10°F stratification

logic utilized by EMI.

Also,

following a series of hot water draws during the efficiency

test (described below), the compressed refrigerant heat

was able to replenish the tank to the 130 °F temperature

level. However, following the heating recovery, neither compressor

or resistance element were activated during standby until

three days later when bottom tank temperatures dropped below

95°F. The compressor was called into operation when the

tank was submitted to a hot water draw which triggered the

ON compressor event in less than a minute.

Table 52 is

a summary of electrical efficiency results generated from

three tests performed in the laboratory. Tank pre-heating

for test #1 and #2 were performed in a similar way, by

forcing the compressor to turn “ON”.

The tank was allowed to loose heat on standby (1-2 days)

and then purged with a draw of at least 30 gallons of new

water. The purge forced the compressor to operate. Preheating

for the test #3 was performed with the tank relatively hot

and only twelve gallons of hot water were purged. This might

explain the higher outlet temperatures read during test 3.

For all three tests, we attempted to heat water so that initial

hot water draws were near 130 °F (+/- 5 °F). However,

we noticed that temperatures at the top of the tank (upper

level) increased slightly with each purge (i.e., 10.7 gallon

draw). During the third test shown in Table 52 for

example, outlet temperatures during the first draw averaged

129.2 °F, but during the last draw temperatures reached

an average of 143.4 °F. The values shown for test #3

shows an overall hot water delivery temperature (T outlet)

of 136.6 °F. The controller never called for compressor

or auxiliary energy when left on standby during the completion

of the test (24-hr.).

Table

52 Electrical Efficiency Results from Laboratory

Tests |

Test |

Total

Gallons Drawn |

Average

T inlet (°F)

|

Average

T outlet (°F) |

Total

Qout kWh |

Total

Qin kWh |

COP |

#1 |

63 |

82.3 °F |

133.2 °F |

7.756 |

3.974 |

1.95 |

#2 |

53.5 |

82.1 °F |

131.2 °F |

6.533 |

3.516 |

1.86 |

#3 |

65.9 |

82.0 °F |

136.4 °F |

8.789 |

4.254 |

2.06 |

Conclusions

The

WattSaver™ heat pump water heater is rated with

an energy factor (EF) of 2.45 and clearly demonstrates that

heating water can be accomplished at a relative higher efficiency

when compared to conventional electric water heaters. Installed

in a conditioned space, and under operation with inlet water

temperatures above 80 °F (e.g., Central Florida summer

water mains temperatures), an average electrical (COP) efficiency

of 2.0 was attained. Other measurements and performance indicators

are summarized in Table 53.

Two

caveats to the heat pump water heater’s performance

was first the delayed recovery during standby which would

present larger hot water temperature variation to the residential

user. This also leads to diminished hot water capacity during

long periods of no hot water use activity. Second, because

the compressor’s discharge refrigerant (i.e., hottest

temperatures) enter the wrap-around heat exchanger at the

top of the tank, the unit demonstrated larger hot temperature

variations at the tank’s upper levels when the top

portion was already pre-heated. These stratified tank temperature

levels differ from those obtained when heating is started

with the tank filled up with mains (colder) water conditions.

Table

53 Summary of Other Measurements and Performance

Overview |

Typical

Cooling

Air

Flow rate: 87 CFM (Figure 87)

Top

cavity/Fan operating : -6.4 pa

Evaporator

Air temp: 73 °F (63%RH entering) / 53.1 °F

(leaving)

Condensate:

502.6 g/hr. (1.1 lb/hr)

Sensible:

1900 Btu/hr.

Latent:

957 Btu/hr

Total

Capacity : 2,857 Btu/hr |

Current

consumption (208 VAC)

Compressor2.9

amps

Fans

(2) : 0.08 Amps/each

Total

3.08 amps |

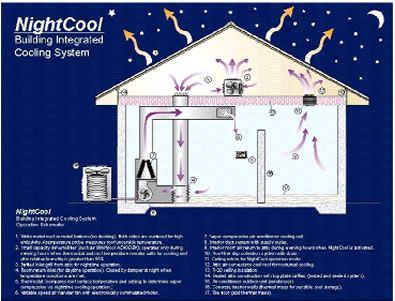

- NightCool - Building Integrated Cooling System

Technical

Background

Using

a building’s roof to take advantage

of long-wave radiation to the night sky has been long identified

as a potentially productive means to reduce space cooling

in buildings. This is because a typical roof at 75 F will

radiate at about 55-60 W/m2 to clear night sky and about

25 W/m2 to a cloudy sky. For a typical roof (250 square

meters), this represents a cooling potential of 6,000 -

14,000 Watts or about 1.5 - 4.0 tons of cooling potential

each summer night. Various physical characteristics (differential

approach temperature, fan power, convection and conductance)

limit what can be actually achieved, however, so that perhaps

half of this rate of cooling can be practically obtained.

Even so, careful examination of vapor compression space

cooling in many homes in Florida shows that typical homes

experience cooling loads averaging 33 kWh per day from

June - September with roughly 9.2 kWh (28%) of this air

conditioning coming between the hours of 9 PM and 7 AM

when night sky radiation could greatly reduce space cooling.

The

big problem with night sky radiation cooling concepts has

been that they have typically required exotic building

configurations. The research literature is extensive. These

have included very expensive “roof ponds” or,

at the very least, movable roof insulation with massive roofs

so that heat is not gained during daytime hours. The key

element of this configuration is that rather than using movable

insulation with a massive roof or roof ponds, the insulation

is installed conventionally on the ceiling. The operation

of the system is detailed in the attached schematic.

During

the day, the building is de-coupled from the roof and heat

gain to the attic space is minimized by the white reflective

metal roof. During this time the space is conventionally

cooled with a small air conditioner. However, at night

as the interior surface of the metal roof in the attic

space falls two degrees below the desired interior thermostat

setpoint, the return air for the air conditioner is channeled

through the attic space by way of electrically controlled

louvers with the variable speed fan set to low. The warm

air from the interior then goes to the attic and warms

the interior side of the metal roof which then radiates

the heat away to the night sky. As increased cooling is

required, the air handler fan speed is increased. If the

interior air temperature does not cool sufficiently or

the relative humidity is not kept within bounds (<55%

RH) the compressor is energized to supplement the sky radiation

cooling. However, by midnight on clear nights, the temperature

of the metal will have dropped sufficiently to begin to

dehumidify the air introduced to the attic. The collected

moisture on the underside of the roof will then drain to

collection points at either side of the soffits so that

the home can be dehumidified during evening hours by way

of only the operation of the blower fan (200-300 W). The

massive construction of the home interior (tile floor and

concrete interior walls) will store sensible cooling to

reduce space conditioning needs during the following day.

Experimental Design

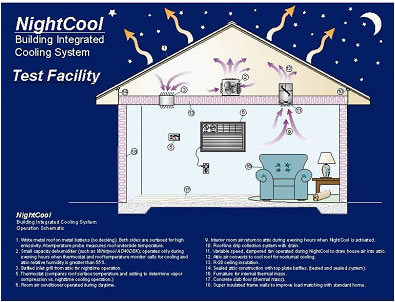

BAIHP

researcher Danny Parker developed an experiment to test

the viability of NightCooling in Florida’s hot-humid

climate. However, construction of a suitable laboratory facility

to conduct this study has been delayed. BAIHP is working

with UCF and local officials to develop a design allowable

under current codes for a pair of free standing, room size

structures to serve as a “control” and a “test” case.

A schematic of the test case and a similar drawing of the

concept in a real home are shown in Figures 88 and 89.

|

Figure 88 -Scehmatic

design for NightCool test facility. |

|

Figure 89 Schematic

of NightCool concept in typical residential building. |

|

You

are here:

You

are here: