- Side By Side Study Of Energy Use And Moisture Control

Comparing Standard Split System Air Conditioning And A

Coleman® Prototype Heat Pump, Bousier

City, LA

In

2001, the BAIHP team conducted research on two homes to

define how tight ducts and a prototype Coleman® heat

pump (proprietary technology) affect energy use and moisture

control in a hot, humid climate. FSEC, in collaboration with

Fleetwood Homes, York International Manufactured Housing

Division (now Stylecrest Sales), and Coleman®, monitored

two nearly identical side-by-side homes in Bossier City,

Louisiana. The homes contained different air conditioning

systems. House A used a standard split air conditioner, while

House B used the Coleman® prototype unit (a more efficient,

two-speed split air conditioner).

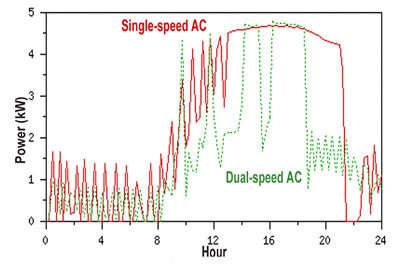

Figure 45 shows the reduced power draw of the two-speed

compressor (green, dotted line) over a 24-hour period on

September 2, 2000. With the unit operating at low-speed for

most of the day, the cooling energy savings were 28% when

compared to the energy use in House A. Average daily cooling

energy was reduced by about 12% over the monitored period.

An added benefit of the two-speed air conditioner was 20%

greater moisture removal on days with an outdoor dewpoint

above 60 F.

|

Figure

45 Power draw

over a

24-hour period, September 2, 2000. |

Savings from Duct Repair and POS Ventilation: In addition

to comparing one house to the other, the BAIHP team also

compared home performance before and after ductwork and ventilation

system changes were made.

To make the comparison, duct and other

leaks were sealed in both houses until the two were equally

airtight. The ventilation method in each home also was

changed from exhaust-only to a positive pressure system (POS).

With exhaust-only ventilation, bathroom fans removed stale

air from the home which caused fresh air to be pulled

in through the building envelope. To simulate occupant

use, two bath exhaust fans were operated by a timer for

three hours in the morning and six hours in the evening.

In contrast to exhaust ventilation, the POS system introduced

a small amount of fresh air on the return side of the air conditioning

cooling coil. A POS system was installed in each home at the

same time the ducts were repaired. Subsequent monitoring looked

at the effects of this alternate ventilation system. Tightening

the ducts and installing a POS ventilation system resulted

in an 18% and 37% cooling savings in the two homes. Only about

2% of these savings were attributable to the ventilation system

change, the remaining savings are a result of duct repair.

|

Figure 45

WSU

Energy House

in Olympia, WA |

This 2600 ft 2 home was built beyond SGC standards and incorporates

Energy Star lighting and appliances. The home (Figure

45) has received significant national exposure through

WSU campus and alumni newsletters, tours, the BAIHP website,

and local and trade media including an article in the Automated

Builder magazine and a feature by KING 5 News of Seattle.

WSU staff uses the house to try out innovative technologies

and testing methods.

In

the 5th budget period, BAIHP staff developed a moisture case

study based on research at the WSU Energy House, published

under a separate Building America project. The WSU Energy

House has been monitored since 2000. Collected monitoring

data includes weather, temperature, humidity, CO 2, CO, and

eight differential pressures. Energy use data

is being collected for water heating, laundry, fireplace

and heating, ventilating, and air conditioning (HVAC). Data

from the house is available on the BAIHP web page (under

Current Data) and has been presented to the building science,

indoor air quality (IAQ) and HVAC research communities at

conferences sponsored by ASHRAE, Air Infiltration and Ventilation

Center (in the UK), HUD/NIST, NFPA, and

BTECC. (See also Appendix D, WSU)

Working

with Ecotope, ASHRAE, and the Energy Conservancy, BAIHP

staff conducted “Delta Q” and “nulling” duct

leakage tests in 2001. Follow up pressure tests and

analysis of test data conducted in 2002 indicate these tests

are effective methods of measuring duct leakage in manufactured

homes, and may be included in the upgrades to the National

Fire Protection Association-501 standards for manufactured

homes.

Blower door and duct leakage testing indicate very good

whole house and duct airtightness (2.4 ACH50 and 61.6 CFM50

out). Tracer gas testing demonstrated that the use of a furnace-based

intake damper does not change the leakage rate of the home.

- Zero Energy Manufactured Home (ZEMH)

|

Figure

46: Zero Energy

Manufactured Home, on site

at

the Nez Perce Fish Hatchery |

BPA,

working with BAIHP staff in Idaho and Washington, provided

funding for the most energy efficient manufactured home

in the country. The RFP was sent to 18 Northwest manufacturers;

Kit HomeBuilders West of Caldwell, Idaho was selected as

the manufacturer of the home. BAIHP staff solicited 24

industry partners to provide energy efficient building

components, including Icynene wall, floor and roof insulation,

a low-cost HUD-approved solar system, sun-tempered solar

design, and Energy Star© windows,

appliances and lighting. Partners include Building America

Team members such as Flexible Technologies, Icynene and

LaSalle. Complete list of specifications provided in Table 24.

The ZEMH (Figure 46) was built in Year 4 along

with a control home. The ZEMH was displayed at the 2002 Spokane

County Interstate Fair before siting at the Nez Perce tribal

fish facility near Lewiston Idaho. Blower door and duct leakage

tests at the plant and on-site indicate that this is the

tightest home ever tested by BAIHP staff.

Working with FSEC and BPA, BAIHP staff installed monitoring

equipment for the ZEMH. Monitoring began in the 5th budget

period and includes the following:

- Total electric use from grid

- Resistance elements in heat pump

- Heat pump compressor and fan motors

- Water heating equipment, including gallons used

- PV energy production (ZEMH)

TABLE

24 Zero Energy Manufactured Home (ZEMH)

and Base

Case Home (Control) |

Component |

ZEMH |

Base |

Wall Structure |

2x6 ft, 16 in on center |

Same |

Wall Insulation |

R21 foam-spray |

R21 batt |

Floor Structure |

2x8 ft, 16 in on center |

Same |

Floor Insulation |

R33 (R22 Foam + R11 batt) |

R33 Blown Cellulose |

Vented crawl space wall |

R14 foil faced foam |

None |

Roof/Attic Structure and

Finish |

16

in on center

40

lb roof load

4/12

pitch metal roofing

|

24

in on center

Standard

30 lb roof load

Same

pitch and finish

|

Roof/Attic Insulation |

R49 foam |

R33 blown cellulose |

Window/Floor area ratio |

12% |

Same |

Windows |

Vinyl Frame, Argon filled,

low-e, Energy Star Approved |

Same |

Window Shading |

Dual blinds, heavy drapes,

awnings |

Single blinds, light drapes |

Doors |

U=0.2 metal, foam w/thermal

break |

Same |

Solar |

Solar

ready design (mounts, flashings and electrical chase)

4.2

kW peak rated PV system with a 4 kW inverter and

12 kWh battery array

|

None |

HVAC |

2

ton unitary air-source heat pump

12

seer, 7.8 HSPF

|

Same |

Zone heat |

150 W Radiant Panel in

kitchen |

None |

Ducts and cross over |

R8

crossover

Flex

Flow crossover system

Mastic

with screws

More

efficient duct design

|

R8

crossover

Sheet

metal elbows

Standard

foil tape

|

Lighting |

100% Energy Star T8 and

CFL fixtures |

T12 and Incandescent fixtures |

Appliances |

Energy Star washer and

dryer, refrigerator, dishwasher |

Standard equipment |

Whole House Ventilation |

Heat Recovery Ventilator

w/HEPA, continuous operation (turned off in 8/04) |

Quiet (low-sone) Energy

Star exhaust fan, continuous operation |

Spot Ventilation |

Energy Star bath fans,

std. Kitchen fan |

Quiet (low-sone) bath

fans, std. Kitchen fan |

Ceiling Fans |

Energy Star with dimmable

CFL |

Standard with Incandescent

bulbs |

Domestic Hot Water |

PV controlled, active

anti-freeze solar water system, with 80 gallon storage,

and 64 ft 2 of collector area solar pre-heat tank (pre-plumbed),

40 gallon standard tank EF=0.93 |

EF=0.88 standard electric |

Air Sealing |

Wrap

with tape flashing

Marriage

line gasket (new product)

Penetrations

sealed with foam insulation

|

Wrap

without tape flashing

Standard

practice marriage line sealing

|

Air/Vapor Barrier |

Walls

and Ceiling: Painted Drywall

Floor:

Floor decking

|

Same |

Data logger collects 15 minute data from wired sensors and

transmits daily to the host computer at FSEC via modem. Summary

data reports are available at www.baihp.org under “Current

Data.” Plug-type loggers were installed in mid March

2003 to sub-meter the energy use of the refrigerator, freezer

and clothes washer in each home, as well as the radiant heat

panel and HRV in the ZEMH. Data from these loggers was collected

by occupant readings in mid-December 2003.

Preliminary findings

Measured

net energy use of the ZEMH 6% is lower than the base home,

not normalized for occupant behavior. This also does not

take into account the fact that the ZEMH’s

PV system was only fully operational for one month.

The ZEMH required 45% less space heating energy, possibly

due to improved building envelope measures, and the lack

of consistent HRV operation.

The measured envelope leakage in the ZEMH was 2.0 ACH50,

much lower than the base home (indeed, lower than any other

NEEM home tested in the field) and substantially tighter

than typical HUD code homes.

The ZEMH total duct leakage was 46% lower than the base

home; leakage to the outside was 405% lower than the base

home. The BAIHP staff speculates that the unprecedented low

leakage to the outside value is the result of the ducts in

the ZEMH being located within the conditioned space, and

effectively within the pressure envelope of the home, surrounded

as they are by foam insulation.

The solar water heating system in the ZEMH provides most,

if not all of the hot water needed during the summer months,

and roughly 45% of the total hot water demand. The PV system

with net metering provides 38% of the total ZEMH energy use.

The

project highlights the importance of occupant choices and

behavior on the performance of energy efficient housing.

Based on the preliminary monitoring data and occupant surveys,

the behavior patterns of the ZEMH occupants are not themselves “energy

efficient”. These patterns create the appearance of

a less efficient home. On the other hand, the behavior of

the ZEMH occupants may shorten the payback for the innovative

technologies of the ZEMH.

BAIHP staff also performed a benchmarking analysis on the

ZEMH, as part of the overall benchmarking effort. The ZEMH

reached a level of 60% above the NREL prototype, which indicates

the difficulty of obtaining a high benchmarking score.

- Manufactured Housing Indoor Air Quality Study

In the spring of 2003, BAIHP initiated a study with Palm

Harbor Homes (PHH) to evaluate the energy savings from a

Building America Manufactured Home, compared to a standard

Palm Harbor Home.

These

two homes were built in the fall and set up on PHH’s

model center in Plant City, Florida.

The monitoring plan called for measurements of volatile

organic chemical (VOCs) levels, air conditioning energy use

and associated indicators such as indoor and outdoor conditions.

Both homes have split system air conditioners, SEER 15 in

the BA model, and SEER 10 in the Base Case model.

The two homes were instrumented in November, however, due

to a PHH phone service conflict, no data was taken during

this budget period. Data collection is expected to commence

in May of 2004.

VOC measurements were conducted in collaboration with LBNL.

The VOC data revealed significantly higher VOC levels in

the Building America home than in nearby control models of

a similar age. Normally, PHH would move furniture in from

a previous model, but in an effort to ensure high quality

in the BA model, PHH purchased all new, all wood furniture.

This is believed to be the source of VOCs in the BA model.

BAIHP and LBNL researchers will work to verify what caused

the elevated VOC level in the next budget cycle.

- Manufactured Housing Laboratory – Ventilation

Studies

Ventilation Study

The MHLab (Figure 47) is a research

and training facility of 1600 ft 2. This Energy Star® manufactured

home has two separate heating and cooling systems:

1. An overhead duct system connected to a package unit air

conditioner with electric resistance heating.

2. A floor-mounted duct system connected to a split system

air conditioner, also with electric resistance heating.

Only the floor mounted duct system was used in these ventilation

experiments.

Introduction

|

Figure 47 Manufactured Housing Laboratory

at FSEC (above and below) was site for study of six

residential ventilation systems. |

|

Ventilation is a HUD code requirement. The goal of ventilation

is to add fresh air to the home. This may be accomplished

by supplying outside air to the house or mechanical system,

exhausting air from the house (which consequently pulls air

into the house through joints in the walls, floor, and ceiling),

or a combination of the two.

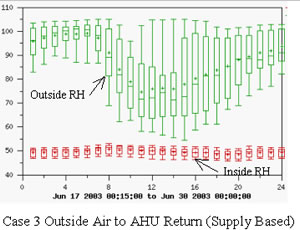

Supply based ventilation tends to slightly pressurize the

home whereas exhaust based ventilation does the opposite

slightly depressurizing the house. The disadvantage of supply

based ventilation is that it forces conditioned air into

the floor, wall, and ceiling cavities, possibly leading to

condensation or mold growth in cold climates and during the

heating season. Likewise the disadvantage of exhaust systems

is that they pull unconditioned outside through the floor,

wall, and ceiling cavities into the conditioned space, possibly

leading to condensation, mold growth, or uncomfortably high

indoor humidity levels in hot and hot-humid climates and

during the cooling season. The six residential ventilation

strategies evaluated are described in Table 25.

House Operation and Experimental Procedure

Occupancy Simulation: Automated, computer controlled

devices, such as appliances, showers, and lighting, simulate

the sensible/latent heat generation and carbon dioxide (CO

2) production of a family of four persons with periodic showers,

cooking and cleaning.

The simulated latent occupancy load from breathing,

bathing, cooking, and laundry was achieved by adding 14 to

15 pounds of water per day based on documentation of "average" household

operation based on ORNL research conducted by Jeff Christian.

Water vapor was injected into the space using a vaporizer at

a rate of approximately 0.4 lbs per hour continuous and an

additional 0.4 lbs per hour during the evening hours.

Table

25 Ventilation Strategies Studied in the MHLab |

Case

(Name)

|

Strategy |

Description |

# 1

(None).

|

No mechanical ventilation |

Base Case scenario included only the

heating and cooling system of the home with no outside

air (OA) ventilation. |

# 2

(Spot)

|

Spot ventilation (exhaust only) |

Bathroom and kitchen exhaust fans.

Operation scheduled for 30 minutes after a simulated

moisture producing event such as a shower or oven use. |

# 3

(OA)

|

Outside air (supply based) |

Dedicated, filtered outside air duct

to return plenum when the heating or cooling system

is operating. Quantity of ventilation air provided

depends on air handler run-time. |

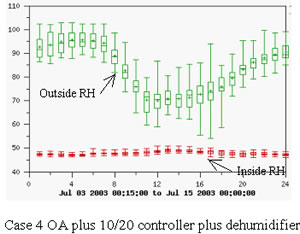

# 4 (Dehumid) |

Outside Air plus 10/20 Cycle and Dehumidification

(Supply Based) |

Same

as #3, except with an added air handler fan controller

(10-minute “on” -

20-minute “off” minimum duty cycle). Provides

scheduled ventilation when no cooling or heating is

called for. A stand alone room dehumidifier (set to

approximately 50% RH) located in vicinity of the return

air grill. |

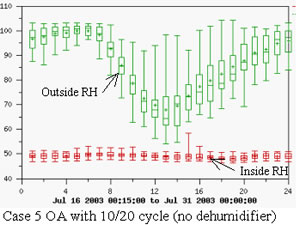

# 5

(10/20 Cycle)

|

Outside Air plus 10/20 cycle (Supply

Based) |

Same as #4, except without the room

dehumidifier. |

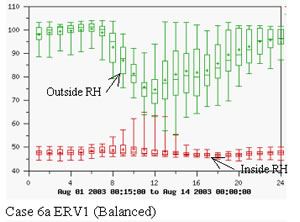

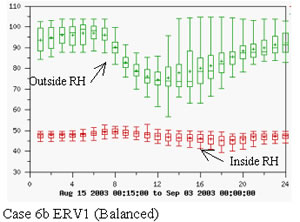

# 6 (ERV1) (ERV2) |

Energy recovery ventilator (ERV1, ERV2) |

Two different enthalpy transfer media

were used. Outside air was drawn in through the ERV

at a rate to meet the ventilation requirements. |

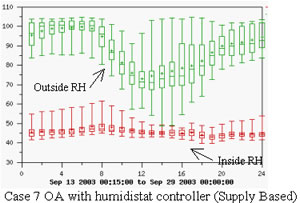

# 7

(Hstat)

|

Outside Air plus Humidistat (Supply

Based) |

This is a modified air handler fan

speed control. When dehumidification is needed, the

air handler fan is operated at lowest speed for enhanced

latent control. A higher speed is selected when sensible

cooling is needed. Ventilation air supplied via an

outside air duct, with air handler fan operation controlled

as in #4. |

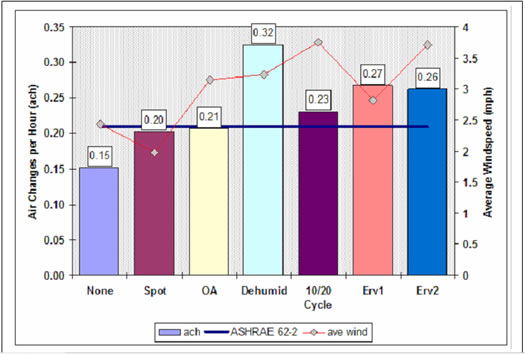

Ventilation Rate: Researchers conducted whole house

air tightness tests using sulfur hexafluoride as a tracer gas

for a decay analysis (Figure 48) to determine if each

ventilation strategy met the ASHRAE 62-2 Ventilation Standard

during the test period. The spot ventilation strategy (#2)

did not meet the standard on a daily basis as the runtime was

not long enough. The outside air method (#3) was marginal in

meeting the standard. Strategies #4-#7 met the standard.

|

Figure

48 Results of

tracer gas decay testing indicating operational

infiltration

(house not under test pressure) rates measured for each ventilation strategy.

ASHRAE Standard 62.2 was the target ventilation rate, not met by Spot

or

OA strategies. Note: Wind speed averaged over 2 hour infiltration test. |

Whole House and Duct Air Tightness: The average

whole house air leakage (CFM50) was 1224 (ACH50 of 5.4).

The target normalized duct leakage is Qn #6%, where Qn=CFM25/conditioned

area, this is the same as the duct leakage target in the

Manufactured Home Energy Star program. The total duct system

leakage in the MHLab Qn total=5% (CFM25 total = 75) with

leakage to the outside measured to be Qn (out)=3% (CFM25

out = 45), well under the leakage target.

Interior temperature and relative humidity: A digital

thermostat maintained interior temperature at 75 degrees

Fahrenheit. Interior temperature and relative humidity

sensors are located on the same wall as the thermostat, at

approximately the same height from the floor. Dedicated interior

relative humidity control was only available with the dehumidifier

strategy, and was a byproduct of cooling coil operation

in the other strategies.

Cooling/ventilation power usage

With all mechanical ventilation systems, additional energy

use from both increased conditioning loads and fan (if present)

power is expected. The split system with the floor duct system

is a 12 SEER system with a rated cooling capacity of 30.2

kBtu. The ventilation strategies that required the use of

the air handler fan, an energy recovery ventilator, or the

dehumidifier had the energy use added to the cooling energy.

The dehumidifier strategy did use the most energy for cooling;

however, it should be noted that this test occurred during

the hottest ambient conditions.

Table

26 Average Ambient and Building Conditions |

|

Case 1 None |

Case 2 Spot |

Case 3 OA |

Case

4 Dehumid |

Case 5 10/20 |

Case 6 ERV1 |

Case 6 ERV2 |

Case 7 Hstat |

Indoor

Temp (°F) |

74.5° |

74.5° |

74.7° |

74.9° |

74.0° |

74.1° |

74.4° |

74.8° |

Indoor

Temp Max (°F) |

75.0° |

75.2° |

75.5° |

76.0° |

75.0° |

74.9° |

75.4° |

76.0° |

Indoor RH (%) |

49.2% |

45.7% |

49.5% |

47.9% |

49.1% |

47.8% |

47.2% |

45.7% |

Indoor

Dewpoint (°F) |

52.4° |

54.2 |

54.5 |

53.9 |

53.7 |

53.1 |

53.0 |

52.4 |

Outside

Temp (°F) |

78.6° |

78.6° |

78.4° |

82.1° |

79.8° |

79.3° |

80.8° |

79.2° |

Outside RH (%) |

89.2% |

79.5% |

87.7% |

83.4% |

87.0% |

90.0% |

86.9% |

88.1% |

Δ Temp (°F) |

4.3° |

4.0° |

3.7° |

7.1° |

5.8° |

5.1° |

6.5 |

4.4 |

Δ Dewpoint (°F) |

18.6° |

20.7° |

19.5° |

22.4° |

21.4° |

22.7° |

23.3° |

22.6° |

Solar Rad. (kWh/m 2) |

53.5 |

107.3 |

68.9 |

76.3 |

86.8 |

66.3 |

101.9° |

77.1° |

Rainfall (Inches) |

3.6 |

0.5 |

4.7 |

0.1 |

4.0 |

5.1 |

3.2 |

4.9 |

Condensate (lbs) |

617 |

905 |

920 |

1131 |

1118 |

1034 |

1685 |

1282 |

Δ P

WRT Out (Pa) |

-0.2 |

0 |

0.1 |

0.4 |

0 |

-0.2 |

-0.2 |

0.1 |

Minimum RH |

42.1% |

38.8% |

45.8% |

46.2 % |

46.3% |

44.2% |

39.3% |

39.7% |

Maximum RH |

53.3% |

55.2% |

53.2% |

51.0 % |

58.4% |

64.8% |

53.0% |

61.4% |

Mean RH |

46.1% |

49.2% |

49.5% |

47.9 % |

49.0% |

47.8% |

47.2% |

45.7% |

RH Standard Deviation |

1.272 |

1.471 |

1.673 |

0.845 |

1.231 |

2.194 |

2.108 |

3.07 |

RH Range |

11.2 % |

16.3 % |

7.4 % |

4.8 % |

12.1 % |

20.6 % |

13.7 % |

21.7 % |

Findings

The

cooling energy required to maintain the 75°F interior

set-point appeared to vary as a result of the temperature

difference across the envelope (Table 26). A linear regression

analysis was performed to compare energy use of the ventilation

strategies as a function of temperature difference across

the envelope (Table 27). The power use at the average temperature

difference of five degrees Fahrenheit is shown in bold.

- Case 4, the dehumidifier system, has the highest average

power at 1592 watts.

- Case 7 (humidistat controlled fan speed or Hstat) is

second highest at 1485 watts.

- Case 5 (10/20 cycle controller) used the least power

at 1315 watts.

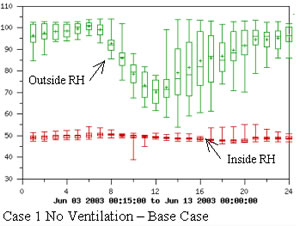

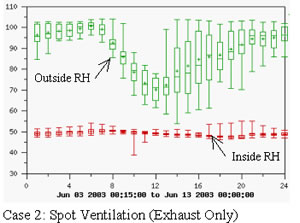

As might be expected, interior relative humidity had the

least variance with the dehumidification system with a low

of 46% and a high of 51% (Table 26 and Figure 49).

The best performing system, Case 4 (10/20 cycle plus dehumidifier),

was able to maintain the relative humidity at a nearly constant

level for almost 80% of the test period. The next best performer

was Case 2 (spot ventilation). Humidity levels during the

test period are graphed in Figure 49.

Table 27

Cooling and ventilation power (watts) usage as a function

of temperature difference across the building envelope |

ΔTemp

(°F) |

Case

1 None |

Case

2 Spot |

Case

3 OA

|

Case

4 Dehumid |

Case

5 10/20 |

Case

6 |

Case

7 Hstat |

ERV1 |

ERV2 |

-5 |

487 |

499 |

475 |

499 |

411 |

459 |

367 |

526 |

0 |

924 |

911 |

949 |

1046 |

863 |

915 |

880 |

1006 |

5 |

1361 |

1324 |

1424 |

1592 |

1315 |

1370 |

1393 |

1485 |

15 |

2236 |

2150 |

2372 |

2685 |

2219 |

2280 |

2418 |

2443 |

Figure

49 Average

hourly relative humidity profiles for each

strategy |

|

|

|

|

|

|

|

|

Conclusions

The

operation of a correctly sized air conditioning system

with a supplemental dehumidification system to pre-condition

the outside air and provide additional dehumidification of

the space appears to provide the best interior humidity control

(Table 26, in bold) with only a slight increase in energy

usage – about 200 watts (Table 27). This is represented

by Case 4 of this study. Only this strategy was able to maintain

the interior humidity conditions in a range of less than

5% (Table 27, in italics).

Though

all of the strategies did provide some humidity control

over the test period, it is most likely a result of the

run time afforded by the correctly sized air conditioning

system and the consistent simulated interior sensible load.

When an air conditioning system operates for extended periods

of time, the removal of moisture from the air stream is

enhanced (Khattar, Swami & Ramanan

1987).

Additional

testing with other ventilation strategies in the MHLab

will be undertaken in the next budget period.

|

You

are here:

You

are here: