- Manufactured

Housing Energy Use Study, North Carolina A&T

Side-by-side

monitoring of two manufactured homes at North Carolina

Agricultural and Technical State University (NCA&TSU),

evaluated the value of a variety of energy saving technologies

and techniques. (Figure 50 and Table 28) Home instrumentation

measured energy consumption as well as interior and exterior

climatic conditions. The “standard home,” designed

and built to basic HUD code requirements, represented the

control home. Modified to use at least 50% less energy, the “energy

home” met Building America standards. Cooperating researchers

at NCA&TSU and FSEC investigated energy feature performance

and compared actual energy used to energy modeling program

predictions. In-situ energy performance data provided researchers

with interesting information on both issues.

|

Figure 50 Side-by-side

monitoring of

manufactured homes at NCA&TSU. |

Each

model contained 1,528 ft 2 of living area with nearly identical

floor plans. Though the homes were unoccupied during the

testing, home lighting and water heating use was simulated

with timers. A datalogger in each home recorded: (1) the

interior and exterior temperature and humidity along with

solar radiation and wind speed, (2) the home’s total

power consumption, (3) the air conditioning/heat pump compressor,

air handler fan, and electric resistance heater use (primary

heater in the standard house, backup or emergency heater

for the energy house), and (4) water heating and water usage

data.

The energy house features combined higher insulation values,

improved windows, centralized and airtight duct design, high

efficiency heat pump, and a solar water heater. Feature-by-feature

construction differences are highlighted in Table 28.

Table

28 Specifications of Standard and Energy Construction |

Characteristic |

Standard House |

Building America

House |

square footage |

1528 |

1528 |

floor insulation |

R-11 |

R-22 |

wall insulation |

R-11 |

R-13 |

ceiling insulation |

R-20 |

R-33 + roof deck radiant

barrier |

windows |

single pane with interior

storm |

low-E double pane |

exterior doors |

storm door on front |

storm door on all |

marriage wall seal |

fiberglass pad |

sof-seal gasket |

heating system |

resistance electric |

heat pump HSPF 7.5 |

cooling system |

central air conditioning

SEER10 |

central heat pump SEER12 |

system size |

3 tons |

2 tons |

water heating |

electric

water heater – 40

gallon |

solar

water heater – 66

gallon |

duct joints |

industry standard |

sealed with mastic |

duct leakage |

*CFM5out = 145 |

CFM25out = 83 |

house leakage |

**ACH50 = 10 |

ACH50 = 9 |

*Cubic

feet per minute

**Air changes per hour |

Data collection on the two homes began in early January 2001

and continued through this reporting period. Palm Harbor Homes

in Siler City manufactured both homes, the results for program

year three and four are detailed below.

Year 4 Side-by-Side Monitoring Results

During

Phase 2, modifications were made to the solar water heating

system in the energy efficient housing unit to help improve

the performance this system. Further, a number of the incandescent

light bulbs in the energy unit were replaced with compact

fluorescent bulbs. These changes were staged to allow an

evaluation of the effect of each measure on the home’s

energy use.

Based on investigative results, it can be concluded that:

- Changes

in the building envelope, HVAC and duct systems, and fenestrations

in the energy home met researchers’ 50%

energy use reduction goal. Measured annual energy savings

for heating and cooling energy was 58%, and 53% for heating,

cooling, and hot water production.

- Care

should be exercised in the manufactured housing unit

setup or relatively minor construction deficiencies can

significantly reduce a home’s energy efficiency.

Many of these items are invisible to the homeowner; therefore

procedures must be developed to ensure that deficiencies

do not occur during setup.

- The

Energy Gauge energy analysis program appears to give

a reasonably accurate prediction for expected energy use

reduction in a typical manufactured housing configuration.

The predicted energy savings for the housing units evaluated

in this investigation ranged from 54% to 63%, while the

measured values ranged from 53% to 58%. Version 2.0 of

the Energy Gauge Program provided a more accurate energy

savings prediction than the older software versions.

- An

increase in pipe and tank insulation can increase not

only the energy efficiency of a solar water heater by reducing

stand-by losses, but also can reduce the cooling load in

a manufactured housing unit and increase the overall energy

efficiency of the water heating unit. Even small amounts

of exposed piping can significantly affect the energy efficiency

of the water heating system.

- While

providing essentially the same lighting levels, replacing

incandescent lamps with compact fluorescent bulbs not

only reduces lighting energy use, but also reduces the

home cooling load.

The total measured energy used by each of the housing units

for cooling and heating are shown in tables below. Table

29 shows the energy used for heating and cooling the standard

housing unit from January through August of 2002. The standard

home datalogger was struck by lighting in mid-August 2002.

Data after this point was not included since only partial data

is available and performance comparisons were not possible. Table

30 shows a summary of the cooling and heating energy used

by the energy housing unit. Tables 31 and 32 list

the energy use for hot water production for the standard and

energy units, respectively.

Table

29 Cooling and Heating Energy Use, Standard House Actual

Values (kWh) |

|

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

492.4 |

447.6 |

648.6 |

1741.1 |

2495.3 |

849.6 |

628.8 |

384 |

566.3 |

990.8 |

852.9 |

1066 |

Phase

2 |

|

2120.2 |

1717.1 |

1227.6 |

502.0 |

438.0 |

939.4 |

1079.4 |

511.2 |

Table

30 Cooling and Heating Energy Use, Energy Star House |

|

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

337.3 |

205.7 |

150.8 |

452.8 |

1087.3 |

472.8 |

426.9 |

184.8 |

528.3 |

891.5 |

850.9 |

671.6 |

Phase

2 |

|

680.7 |

537.1 |

378.1 |

241.9 |

311.8 |

603.0 |

668 |

626.6 |

Table

31 Domestic Hot Water Use, Standard House |

|

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

197.8 |

267.7 |

250.2 |

212.6 |

0 |

0 |

217.6 |

244.9 |

258.1 |

227.5 |

207.9 |

213.5 |

Phase

2 |

|

294.6 |

280.9 |

283.2 |

264.9 |

280.2 |

192.2 |

200.3 |

85.2 |

Table

32 Domestic Hot Water Use, Energy Star House |

|

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

133.4 |

176.2 |

204.2 |

189.9 |

0 |

0 |

245.5 |

184.4 |

183.0 |

141.2 |

152.3 |

126.6 |

Phase

2 |

|

251.1 |

212.0 |

202.8 |

145.9 |

157.3 |

74.8 |

80.3 |

83.0 |

Also

listed in each table are the monthly energy use values measured

during the first phase of this investigation, January through

August 2001. Please note that the energy housing unit data

prior to August 2001 is suspect due to duct and HVAC system

problems later corrected. The entire data set, including, temperature,

relative humidity, solar radiation, and power use is listed

on the FSEC web site www.infomonitors.com.

The total energy used for water heating and central cooling

over the period of August 1 through August 15 was 363.5 kWh

for the energy home and 596 kWh for the standard home. This

represents a 40 % reduction in energy use between the two homes.

The total energy used over the period of August 1 through

August 15 for water heating was 27.13 kWh for the energy house

and 85.18 kWh for the standard home. This represents a 68%

reduction in energy use with the solar water heating system

and compares well with the June and July reductions of 63%

and 60%, respectively. Consistent findings indicate that the

tank and piping insulation has reduced the standby tank losses

and improved the solar water system efficiency.

In the energy housing unit, three of the 100 watt incandescent

lamps that were on the evening four-hour timed duration were

exchanged for 25 watt compact fluorescent lamps on June 4th.

This change did appear to have a small effect on the cooling

load in the energy housing unit. The relative cooling energy

used by each of the housing units from June, 2002 through August

2002 showed a small change. The percentage reduction in cooling

energy used by the energy housing unit increased from about

30% to 38%. However, it is difficult to isolate the effects

of the improvements in the solar water heating system insulation

and the effects of the compact fluorescent bulbs. In any event,

these effects appear to be much smaller than that produced

by the hot water system changes.

Year

3 Side-by-Side Monitoring Results:

|

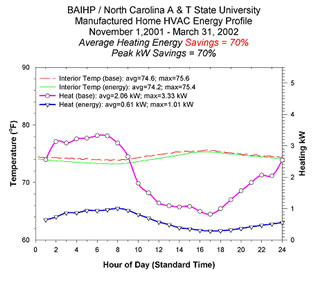

Figure 51 Heating

season consumption

and savings for side by side study

of

Energy Star Manufactured Housing. |

Heating

system savings (2001 to 2002) were a remarkable 70% during

Phase 1. Cooling energy season savings were 36%, less than

heating but still very substantial. The combined heating,

cooling, and water heating savings were 52% for a 9-month period. (Figure

51)

In

addition to the energy monitoring effort, NCA&TSU

researchers investigated the feasibility of replacing the conventional

framing/envelope used in manufactured/industrial housing with

alternative systems. Included in this evaluation, was an analysis

of the energy impact of using aerated autoclaved concrete (AAC)

flooring systems and structural insulated panels (SIP) to supplant

traditional wall and roofing

systems. The economic viability

of using AAC blocks for structural skirting /foundation around

the model units also was evaluated.

Analysis’ results

determined:

The best manufactured home energy performance can be achieved

using the SIP wall and roof systems with the AAC plank. This

performance can be further enhanced with an R-8 unvented

crawl space. Though a manufactured home performs best with

these alternative systems, the cost to include them may not

make economic sense.

- AAC planks can be designed to replace both the steel frame

and flooring systems for HUD code manufactured housing units

and modular units. These planks also can be modified to incorporate

built-in insulated ducts.

- AAC planks are pre-manufactured and require less assembly

labor than a typical stick framed unit, but including the

plank flooring would increase framing costs by 28%. The heavier

weight of an AAC system might exacerbate high framing costs.

Similarly, comparative analysis results found that replacing

a conventional framing system with a SIP system would increase

framing costs by 66%.

- At the current prices for energy and wood products, neither

the AAC plank system nor the SIP systems are as economically

effective as improvements in the current conventional HVAC

systems, steel and wood framing, sheathing systems, and air

barriers with respect to improving energy performance.

- The use of AAC planks has the potential to be economically

viable in the modular housing market, especially if used

with sealed crawl space foundation systems, where their improved

resistance to moisture degradation would be very important.

- SIP wall and roof systems also could prove to be economically

viable if the price of wood energy increases, and the SIP

manufacturing costs decrease through large volume purchases.

- The

proposed AAC planking system presents a system that is

significantly less affected by water and moisture degradation

and may be effective in reducing manufactured housing units’ susceptibility

to flood damage. These systems also are not susceptible to

termite attack.

- The

savings from reduced transportation damage from greater

durability and increased floor system stiffness were not

addressed in this investigation. It wouldn’t take

many days of damage repair (at about $300/person-day for

personnel costs related to transportation) to vastly improve

the economics of these alternative systems.

- Portable Classrooms

Project Overview

This is primarily a WSU (with subcontractors Oregon and Idaho)

and Pacific Northwest National Lab (PNNL) task. Other partners

include FSEC, UCFIE, the State Energy Offices of Oregon and

Idaho, school districts in Portland, Oregon, in Boise, Idaho

and Marysville, Washington, regional utilities, manufacturers,

and other stakeholders in the Pacific Northwest.

The objective of this task is to promote the adoption of

energy efficient portable classrooms in the Pacific Northwest

that provide an enhanced learning environment, high indoor

air quality, and both substantial and cost-effective energy

savings. BAIHP staff focus on four main goals: (1) offering

technical assistance to portable classroom manufacturers, school

districts, and related organizations, (2) field assessment,

monitoring, and analysis of innovative building technologies

and energy saving features to determine their value, (3) facilitation

of collaborative agreements among regional utilities, northwestern

portable classroom manufacturers and materials and equipment

suppliers, as well as school districts, and state education

departments and their affiliates, and (4) conducting and creating

educational opportunities to advance the widespread adoption

of energy efficient portable classrooms in school districts

nationwide.

The experiences working on the energy efficient portable

were instructive, particularly in the identification of flaws

in portable classroom design. The difficulties that BAIHP staff

encountered demonstrate the importance of well-defined commissioning

protocols, documentation, and coordination among all personnel

that service and install HVAC equipment.

Findings:

- Portable classrooms in the Pacific Northwest are occupied

about 1225 hours per year, or about 14% of the total hours

in a year.

- The

average number of occupants in the standard 28’ x

32’ portable classroom provide an internal heat of

about 480 kWh/year, or 8% to10% of space heating requirements.

- Most of the heat loss in portable classrooms manufactured

after 1990 occurs by air leaking through the T-Bar dropped

ceilings, because they have no sealed air/vapor barrier.

This newly created phenomenon occurred with the incorporation

of the less expensive dropped T-Bar ceiling in place of the

more expensive sheet rock used in older portables. Air leakage

also is increased because of unsealed marriage lines - now

used as a low cost method of meeting the state attic ventilation

requirements.

- Since all portables tested in the project used a simple

seven-day programmable thermostat, the HVAC systems operate

during vacations and holidays.

- Energy codes in Washington, Oregon, and Idaho are high

enough to make beyond-code envelope measures non cost-effective.

- Older portable classrooms under removal consideration

could be retrofitted with new energy efficiency measures

at much less cost than purchasing a new portable classroom.

Installing low-E, vinyl framed windows, insulated doors,

T-8 light fixtures, and caulking and sealing air leaks can

all be cost-effective when refurbishing older portable classrooms.

HVAC system replacement in older portable classrooms will

be the biggest single cost item, ranging from $4500 to $6500.

- CO 2 sensors appear to be unreliable as a control strategy.

Those installed by field crews and monitored by dataloggers

in this study did not match the readings shown by the CO

2 sensors which controlled the ventilation systems.

Based on data analysis from years one through four, the following

measures were recommended. New portable classroom procurement,

setup, and commissioning as well as existing classroom retrofit

guidelines produced by the BAIHP study can all be found in

Appendix A.

Recommendations:

- Install 365 day programmable thermostats in all existing

portables and specify these thermostats for new construction.

- In portable classrooms constructed with T-Bar dropped

ceilings, install an air/vapor barrier above the T-Bar system

on the warm side of the insulation. Completely seal all edges

and overlaps.

- If roof rafter insulation is used, seal the marriage line

at the roof rafter joint with approved sealant such as silicon

caulk or foam. Make sure there is adequate ventilation between

the insulation and the roof.

- Conduct an audit of older portables scheduled for disposal

to determine if retrofitting would be more cost effective

than purchasing a new unit.

- Install occupancy sensors to control the ventilation system.

- Specify that new portables contain windows on opposing

walls.

- Specify that new portable units contain exhaust fans on

the opposite side of the classroom from the fresh air supply.

School

Partnerships

|

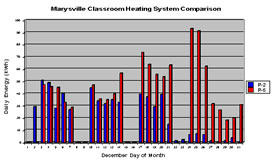

Figure 52 64Energy

efficient portable classroom at Pinewood Elementary

School in Marysville, Washington |

|

Figure 53 Graph

comparing heating system

use of the Pinewood control

portable (P2-Blue) with the energy efficient portable

(P5-Red). Note the energy efficient portable’s

high energy use during the Christmas holidays due to

incorrectly configured heating system controls. |

|

Figure

54 Ventilation

system testing

at North Thurston School District. |

An 895 ft 2 portable classroom (P5) was sited at the Pinewood

Elementary School in Marysville Washington in August 2000.

This unit exceeded current Washington State Energy Code standards

with upgraded insulation in the floor, roof and walls, low-E

windows, and a sensor-driven ventilation system that detects

volatile organic compounds (VOCs). A second portable, built

in 1985, and also located at Pinewood Elementary (P2), served

as the control unit. (Figure 52.)

Energy

use comparisons of the two classrooms show that the energy

efficient portable used considerably more energy than the control

portable. This was attributable to several factors:

- Incorrect

wiring of the exhaust fan, causing it to run continually.

The fan was rewired in 2000 during the summer break. Once

corrected, energy use in the portable declined.

- Incorrect

programmable thermostat settings which were not programmed

to turn the heating and cooling system off during holidays

and vacations. Though energy use was reduced when the portable

was unoccupied, use was still excessive (Figure 53).

- Higher

air leakage in the energy efficient portable than

the control portable. Blower door testing found 19

ACH at

50 Pa in the energy efficient classroom compared to nine

ACH at 50 Pa in the control classroom. Follow-up blower door,

smoke stick, and APT pressure tests indicated that the predominant

leakage path tracked through the T-bar ceiling and into the

vented attic due to an ineffective air barrier in the energy

efficient portable. The control portable contains taped ceiling

drywall.

- No

initial HVAC commissioning by the HVAC supplier or the

school district.

- Significant

HVAC system alterations (including rewiring, ventilation

system VOC sensor replacement with a CO 2 sensor, and modifications

to other aspects of the HVAC control system) during 2001

by maintenance staff and the HVAC supplier, unbeknownst

to BAIHP staff. Calibration testing done by scientists at

the Florida Solar Energy Center on the CO 2 sensors showed

significant drift in output results. This made data collected

virtually unusable.

- The

use of plug-in electric heaters during the winter of 2001

by the resident teacher because of room comfort problems.

This led to significant room temperature variations and monitoring

data showed high plug-load energy use.

- Poor

fresh air flow design with the fresh air intake and exhaust

fan positioned so they create a “short circuit” of

fresh air, bypassing the students and teacher.

BAIHP

staff proposed the following recommendations to Pinewood

Elementary:

- Well-defined commissioning protocols, documentation, and

coordination among all personnel that service and install

the HVAC equipment. This is a critical component of efficient

and healthy classroom operation and should include outside

airflow rate measurements to assess adequate ventilation

and control testing to insure correct system operation.

- Design changes to the portable classroom manufacturer,

including the use of a structural insulated panel system

(SIPS), tighter ceiling barrier and sheetrock ceilings, elimination

of the vented attic, and relocation of the exhaust fan to

the wall opposite the supply air vent.

- Removal

of current HVAC controls and replacement with both an occupancy

sensor-driven control for the ventilation system and a heating

system programmable thermostat. Staff also proposed a classroom

on/off switch to simplify the system turnoff during unoccupied

summer and school vacations.

- Location of exhaust fans in future portables on the wall

opposite the supply air vent.

- Window installation on opposing sides of the classroom

to increase daylight penetration and to assist in passive

cross-ventilation.

Based

on the above recommendations, WSU researchers worked with Marysville

school facility manager and customer representatives from Snohomish

Public Utility District to assist them in setting new construction

specifications for 13 portable classrooms they will procure

during the next reporting period. Marysville School District

will specify a completely sealed ceiling barrier, a new model

heating/ventilation system, a 365 day programmable thermostat,

window placement on opposite sides of the classroom, and exhaust

fan placement on an opposite wall from the fresh air supply.

Washington Schools - North Thurston School District

BAIHP staff also worked with the North Thurston School District

to troubleshoot a portable classroom in Lacey, Washington.

(Figure 54) The classroom was experiencing high energy

use and poor indoor air quality. BAIHP staff tested the classroom,

made recommendations including opening the supply dampers,

installing a wall side vent to better ventilate the classroom

and discussed the specification development process with district

staff. The North Thurston School District now is including

most of the measures listed in the new procurement guidelines

for their future portable classroom purchases. The school district

will investigate the feasibility of installing an air/vapor

above the T-bar dropped ceiling and will record costs for making

these improvements.

Idaho Schools - Boise School District Retrofit

BAIHP staff located a portable classroom at the West Boise

Junior High School in the Boise Idaho School District, occupied

by a teacher who was interested in having the classroom monitored

and retrofitted. The teacher also is an Idaho State legislator

active in education issues, which staff members believe will

increase the chances of implementing the final recommendations.

(Figure 55)

|

Figure 55 Weather monitoring

system installation in the Boise portable classroom. |

BAIHP

staff performed a baseline audit, and installed monitoring

equipment to track the classroom’s

energy use during 2000. In 2001, the classroom was retrofitted

with an efficient HVAC system (controlled by CO 2 sensors),

lighting, and envelope measures. The classroom was then reaudited,

and monitored for the remainder of the year.

BAIHP staff worked with Pacific Northwest National Laboratories

(PNNL) on the pre- and post-retrofit audits, and installation

of the monitoring equipment. In their capacity of

providing

energy management services to the school district, the local

utility Avista Corporation, collected lighting and occupancy

data.

Monitoring data indicates a 58% reduction in energy usage

post-retrofit. Blower door tests indicate a reduction in air

leakage from nine ACH at 50 Pa to five ACH at 50 Pa. Data also

revealed that heating use actually increased on weekends and

holidays because of lack of internal heat gain and because

the HVAC control systems are not programmed to shut off on

weekends and holidays. The total retrofit cost was $9,892.

Monitored data suggests that the CO 2 sensor that controls

the HVAC system is not correctly configured. The system does

seem to react to an increase in CO 2 levels early in the day,

but does not remain on; CO 2 levels only begin to significantly

dissipate after one o'clock PM. BAIHP researchers have noted

the difficulty of correctly configuring these sensors in other

monitored classrooms.

Oregon Schools

Oregon BAIHP staff worked with the Portland Public School

District to procure two energy efficient classrooms. These

were constructed to BAIHP staff specifications and included

increased insulation, high efficiency windows, transom windows

for increased daylighting, a high efficiency heat pump, and

efficient lighting. Staff videotaped the construction of one

classroom.

Monitoring equipment was installed by PNNL staff. Estimates

using the software Energy-10 indicated a total energy consumption

of 9200 kWh, or $583 per year at Portland energy rates. Measured

results showed the Oregon portable used about 6600 kWh for

the monitored period.

Incremental costs for the energy efficiency measures were

$6,705 over Oregon commercial code, including approximately

$2,500 for the HVAC system. This suggests a simple payback

of 10 to12 years.

Initial blower door tests found air leakage rates of 11.3

ACH at 50 Pa. BAIHP staff also identified significant leakage

through the T-bar dropped ceiling and up through the ridge

vents. Other monitoring results indicated that the same HVAC

control problems exist with the Oregon classroom as with the

others studied in this project.

The

Energy Efficient model outperformed code level models in

the Portland area. The older the classroom, the more energy

consumed. Even when compared with new code level models from

the same year, the Energy Efficient model used 35% less energy.

Conventional code level classrooms do not include energy

efficient measures which greatly increases the unit’s operating

costs. Classrooms built more than 10 years ago, use twice

as much energy as the efficient model. Those older than 20

years consume more than three times the amount of energy.

From this study, researches determined that high performance

classrooms can save anywhere from $200 to $1000 dollars a

year in energy costs compared to older, less efficient portables.

A survey sent to teachers and maintenance staff indicates

a high degree of satisfaction with the efficient portables;

the teachers were most impressed with the improved indoor air

quality and increased light levels due to the daylighting windows.

Historical Data Collection

In Idaho, Oregon, and Washington, BAIHP staff worked with

local utilities and school districts to obtain historic energy

use data on portable classrooms. This data will be used to

compare energy usage from the energy efficient portables monitored

in this study.

In Idaho, BAIHP staff worked with Avista Corporation's energy

manager to collect historic data on 14 portable classrooms

in the Boise School District. The classrooms each were equipped

with discrete energy meters; as a result, BAIHP staff was able

to obtain energy usage data for the past three to four years.

A procedure was developed to collect information on portables

at each school in cooperation with the physical facilities

manager and each school lead. Historic data collection continues.

Site visits and walk-through audits are planned for these 14

buildings.

- Duct Testing Data from Manufactured Housing Factory

Visits

Over

the past 10 years, researchers at FSEC have worked with the

Manufactured Housing industry under the auspices of the U.S.

Department of Energy (DOE) funded Energy Efficient Industrialized

Housing Program and the Building America (BA) Program (www.buildingamerica.gov).

FSEC serves as the prime contractor for DOE’s fifth Building

America Team: the Building America Industrialized Housing Partnership

(BAIHP) which can be found online at: www.baihp.org.

Data

and findings presented here were gathered between 1996 and

2003 during 39 factory visits at 24 factories of six HUD

Code home manufacturers interested in improving the energy

efficiency their homes. Factory observations typically showed

that building a tighter duct system was the most cost effective

way to improve the product’s energy efficiency.

BAIHP and others recommend keeping duct system leakage to

the outside (CFM25 out) equal to or less than 3% of the conditioned

floor area, termed Qn out. However, most homes seen in a factory

setting cannot be sealed well enough to perform a CFM25 out

test. Results of many field tests suggest that CFM25 out will

be roughly 50% of total leakage (CFM25 total). Thus, to achieve

a Qnout of less than 3%, manufacturers should strive for a

CFM25 total of less than 6% of the conditioned area (Qn total).

Researchers measured total duct leakage and/or duct leakage

to the outside in 101 houses representing 190 floors (single

wide equals one floor, double wide equals two floors, etc.).

Ducts systems observed in these tests were installed either

in the attic (ceiling systems) or in the belly (floor systems).

Researchers tested 132 floors with mastic sealed duct systems

and 58 floors with taped duct systems.

Of the 190 floors tested by BAIHP, the results break down

thus:

For mastic sealed systems (n=132):

- Average

Qn total = 5.1% (n=124); 85 systems (68%) achieved the

Qn total ≤ 6% target.

- Average

Qn out = 2.4% (n=86); 73 systems (85%) reached the Qn out ≤ 3%

goal.

For

taped systems (n=58):

- Average

Qn total = 8.2% (n=56); 19 systems (34%) reached the Qn

total ≤ 6% target.

- Average

Qn out = 5.7% (n=30), more than twice as leaky as the mastic

average; 5 systems (17%) reached the Qn out ≤ 3%

goal.

The

results show that, while it is possible to achieve the BAIHP

Qn goals by using tape to seal duct work, it is far easier

to meet the goal using mastic. What isn’t illustrated

by the results is the longevity of a mastic sealed system.

The adhesive in tape can’t stand up to the surface temperature

differences and changes or the material movement at the joints

and often fails. Mastic provides a much more durable seal.

Typical factory visits consist of meeting with key personnel

at the factory, factory observations, and air tightness testing

of duct systems and house shells. A comprehensive trip report

is generated reporting observations and test results, and pointing

out opportunities for improvement. This is shared with factory

personnel, both corporate and locally. Often, a factory is

revisited to verify results or assist in the implementation

of the recommendations.

The most commonly encountered challenges observed in the factories

include:

- Leaky supply and return plenums

- Misalignment of components.

- Free-hand cutting of holes in duct board and sheet metal.

- Insufficient connection area at joints.

- Mastic applied to dirty (sawdust) surfaces.

- Insufficient mastic coverage.

- Mastic applied to some joints and not others.

- Loose strapping on flex duct connections.

- Incomplete tabbing of fittings.

- Improperly applied tape

Duct system recommendations discussed in this report include:

- Set duct tightness target Qn equal to or less than 6% total

and 3% to outside.

- Achieve duct tightness by properly applying tapes and sealing

joints with mastic

- Accurately cut holes for duct connections

- Fully bend all tabs on collar and boot connections

- Trim and tighten zip ties with a strapping tool

- Provide return air pathways from bedrooms to main living

areas

Summary of BAIHP Approach to Achieving Tight Ducts in Manufactured

Housing:

- Set

goal with factory management of achieving Qnout<=3%

using Qntotal<=6% as a surrogate measurement while houses

are in production.

- Evaluate current practice by testing a random sample of

units

- Report Qntotal and Qnout findings; make recommendations

for reaching goals

- Assist with implementation and problem solving as needed

- Evaluate results and make further recommendations until

goal is met

- Assist with development of quality control procedures to

ensure continued success

Finally, duct tightness goals can be achieved with minimal

added cost. Reported costs range from $4 to $8. These costs

include in-plant quality control procedures critical to meeting

duct tightness goals.

Achieving duct tightness goals provides benefits to multiple

stakeholders. Improving duct tightness diminishes uncontrolled

air (and moisture) flow, including infiltration of outside

air, loss of conditioned air from supply ducts, and introduction

of outside air into the mechanical system. Uncontrolled air

flow is an invisible and damaging force that can affect the

durability of houses, efficiency and life of mechanical equipment,

and sometimes occupant health. With improved duct tightness,

manufacturers enjoy reduced service claims and higher customer

satisfaction, while homeowners pay lower utility bills, breathe

cleaner air, and have reduced home maintenance.

|

You

are here:

You

are here: