|

2.2

Field Monitoring

To

determine the impact of air handler location on heating and

cooling energy use, researchers measured the amount of air

leakage in air handler cabinets, and between the air handler

cabinet and the return and supply plenums. To assess this

leakage, testing was performed on 69 air conditioning systems.

Thirty systems were tested in the 2001 and 39 in 2002. The

69 systems were tested in 63 Florida houses (in six cases,

two air handlers were tested in a single house) located in

seven counties across the state - four in Leon County in or

near Tallahassee, 17 in Polk County, three in Lake County,

13 in Orange County, one in Osceola County, two in Sumter

County, and 29 in Brevard County. All except those in Leon

County are located in central Florida. Construction on all

houses was completed after January 1, 2001, and most homes

were tested within four months of occupancy.

In

each case, air leakage (Q25) at the air handler

and two adjacent connections was measured. Q25 is

the amount of air leakage which occurs when the ductwork or

air handler is placed under 25 Pa of pressure with respect

to its surrounding environment. Q25 also can be

considered a measurement of ductwork perforation.

To

obtain actual air leakage while the system operated, it was

necessary to measure the operating pressure differential between

the inside and outside of the air handler and adjacent connections.

In other words, it was necessary to know the perforation or

hole size and the pressure differential operating across that

hole. By determining both Q25 and operating pressure

differentials, actual air leakage into or out of the system

was calculated.

Field

Testing Leakage Parameters: Testing was performed on

69 air conditioning systems to determine the extent of air

leakage from air handlers and adjacent connections. Testing

and inspection was performed to obtain:

- Q25

in the air handler, Q25 at the connection to

the return plenum, and Q25 at the connection

to the supply plenum.

- Operating

pressure at four locations - the return plenum connection,

in the air handler before the coil, in the air handler after

the coil, and at the supply plenum connection.

- Return

and supply air flows were measured with a flow hood. Air

handler flow rates were measured with an air handler flow

plate device (per ASHRAE Standard 152P methodology).

- Overall

duct system and house airtightness in 20 of the 69 homes.

- Cooling

and heating system capacity based on air handler and outdoor

unit model numbers.

- The

location and type of filter.

- Dimensions

and surface area of the air handler cabinet.

- The

fractions of the air handler under negative pressure and

under positive pressure.

- The

types of sealants used at air handler connections.

-

Estimated portion of the air handler leak area that was

sealed "as found."

Air

Handler Leakage: Leakage in the air handler cabinet averaged

20.4 Q25 in 69 air conditioning systems. Leakage

at the return and supply plenum connections averaged 3.9 and

1.6 Q25, respectively. Using the operating pressures

in the air handler and at the plenum connections, these Q25

results convert to actual air leakage of 58.8 CFM on the return

side (negative pressure side) and 9.3 CFM on the supply side

(positive pressure side). The combined return and supply air

leakage in the air handler and adjacent connections represents

5.3% of the system air flow (4.6% on the return side and 0.7%

on the supply side). This is a concern, when considering that

a 4.6% return leak from a hot attic (peak conditions; 120oF

and 30% RH) can produce a 16% reduction in cooling output

and 20% increase in cooling energy use (Cummings and Tooley,

1989), and this was only from the air handler and adjacent

connections. (Please see Figure 56.)

"Total"

Duct Leakage: Some important observations were made from

the extended test data in 20 houses. Total leakage on the

return side of the system (including the air handler and return

connection) was 53 Q25r,total. With weighted operating

pressure on the return side of about -100 Pa (including the

air handler), operating return leakage was calculated to be

122 CFM, or 9.7% of the rated system air flow.

Total

leakage on the supply side of the system (Q25s,total)

was very large, at 134. The ASHRAE 152P method suggests using

half of the supply plenum pressure as an estimate of the overall

supply ductwork operating pressure, if the actual duct pressures

are not known. For the 20 systems with extended testing,

supply plenum pressure was 73.3 Pa. Based on a pressure of

37 Pa, actual leakage should be 167 CFM or about 13.3% of

the rated air flow. To test the ASHRAE divide by two method,

supply duct operating pressure measurements were taken from

14 representative systems. These averaged 35.9 Pa, compared

to 65.7 Pa for the supply plenums for those same 14 systems.

For these systems, the duct pressure was 55% of the supply

plenum pressure - making the ASHRAE method a reasonable method

for estimating central Florida home's supply ductwork

operating pressures.

However,

the ASHRAE method wasn't reasonable for estimating

central Florida home's return ductwork operating pressures.

For these 20 systems, 38% of the Q25r,total was

in the air handler and 62% of the Q25r,total was

in the return ductwork. Given an air handler pressure of

-133 Pa, a return plenum pressure of -81.5 Pa, and return

duct pressure of approximately -70 Pa, the weighted return

side pressure was approximately -95 Pa. By contrast, the

ASHRAE method predicted -41 Pa. Clearly, in systems with

a single, short return duct plenum like those commonly found

in Florida, the actual operating pressure should be greater

than the return plenum, maybe by as much as 1.2 times the

plenum pressure.

Return

side leakage is available on 58 of the 69 systems. Return

leak air flow (Qr,total) combined for the air handler,

return connection, and the return ductwork was found to be

152.4 CFM, or 11.8% of total rated system air flow for this

group. For this larger sample, Qr,total is considerably

greater than for the 20 houses with extended testing. These

alarming results show that even in these newly constructed

homes about 12% of return air and 13% of supply air duct systems

are leaking.

Duct

Leakage to "Out": In 20 homes, duct leakage to "out"

was measured. (Please see Table 15, below.) On average,

56% of the leakage of the return ductwork and supply ductwork

was to "out." "Out" is defined as outside the conditioned

space, including buffer spaces like an attic or garage. The

fraction of leakage that was to "out" varied by air handler

location. For return ductwork, the proportion of total

leakage to "out" is 81.4% for attic systems, 67.6% for garage,

and 28.0% for indoors. For supply ductwork, the proportion

of total leakage to "out" was in the range of 52% to 56% for

all three locations.

| Air

Handler Location |

Return |

Supply |

Entire

Duct System |

| Attic |

81.4% |

56.5% |

63.2% |

| Garage |

67.6% |

51.7% |

56.0% |

| Indoors |

28.0% |

52.6% |

37.1% |

Table

15. Portion of duct leakage to outdoors [(Q25,out/Q25,total)

* 100].

The

attic return ductwork was the most predictive variable to

"out" leakage findings. All of the return ductwork for attic

units was located in the attic. Much of the return ductwork

for other units was located in the house. As a consequence,

the energy penalty associated with locating the air handler

in the attic was greater than indicated in the computer modeling

results in Table 16, since the modeling only considered the

leakage of the air handler cabinet and the adjacent connections,

and not the return ductwork leakage.

| |

Attic

(CFM) |

Garage

(CFM) |

Indoors

(CFM) |

Combined

(CFM) |

| Air

Leakage |

Total |

Out |

Total |

Out |

Total |

Out |

Total |

Out |

| Q25,r

[58] |

61.9 |

50.4 |

93.3 |

63.1 |

67.8 |

19.0 |

75.7 |

44.9 |

| Q25,s

[20] |

109.1 |

61.6 |

170.6 |

88.2 |

119.5 |

62.9 |

134.3 |

71.4 |

| Qr

[58] |

118.1 |

96.1 |

194.4 |

131.4 |

134.6 |

37.7 |

152.4 |

90.4 |

| Qs

[20] |

135.6 |

76.6 |

212.0 |

109.6 |

148.5 |

78.1 |

166.9 |

88.7 |

Table 16. Duct

leakage "total" and to "out" for three locations, for both

25 Pa test pressure and for actual system operating pressure.

Sample size is in [brackets].

Table

16 (above) shows that the operating supply leakage to "out"

was large for all three air handler locations, averaging 89

CFM. The average operating return leakage to "out" was slightly

larger, at 90 CFM. However, there was a large variation between

air handler locations; 96 CFM for attic systems, 131 CFM for

garage systems, but only 38 CFM for indoor systems. From

an energy perspective, the attic systems experienced the greatest

"real" energy penalties, because all of the return ductwork

and air handlers were located in the attic. (Please see Table

15, p. 80.) By contrast, a majority of the return leakage

for the garage systems likely came from the garage (which

is considerably cooler than the attic). For indoor systems,

the return leakage to "out" most likely originated from the

attic. However, since the return leakage was so much smaller,

the energy impact was likely considerably less than both the

attic and the garage systems.

Correlation

of Supply Duct Leaks with Number of Registers: When analyzing

the supply leakage in the extended test data, a surprising

correlation was observed. This correlation indicated a systematic

and consistent duct fabrication problem across a wide range

of air conditioning contractors. Figure 57 illustrates this

correlation, showing that each supply duct has a remarkably

predictable total duct leakage. The coefficient of determination

is 0.86, indicating that 86% of the variability in total supply

duct leakage was explainable by the number of supply registers.

Figure 58 shows a similar relationship between supply leakage

to "out" and the number of supply registers. In this case

the coefficient of determination was 0.69, indicating that

69% of the variability in total supply duct leakage was explainable

by the number of supply registers. Note that one of the two

houses with 13 registers showed considerably less leakage

than expected. In this case, supply ducts were located in

the interstitial space between floors. When the house was

taken to -25 Pa, it is probable (though not measured) that

the interstitial spaces were substantially depressurized as

well, so leaks in those supply ducts would show less air flow

(i.e., less pressure differential = less leakage air flow)

and therefore be under-represented.

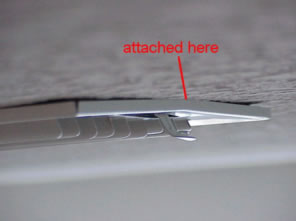

The

following two figures (Figures 57 and 58) suggest that a duct

leakage problem occurs in nearly all new homes. Researchers

identified three issues that create most of the leakage: (1)

the connection of the supply register or return grill, (2)

the boot (supply box) to sheet rock connection, and (3) the

flex duct to collar connection. The supply register or return

grill leakage typically shows as supply leakage in the "total"

test. It usually occurs when the register or grill does not

fit snugly to the ceiling or wallboard. Issues two and three

show up as leakage to both "out" and "total." (Please see

Figures 59 and 60.)

|

|

| Figure

57. Supply CFM25 "total" leakage versus the number

of supply registers. |

Figure 58. Supply CFM25 "out" leakage versus the

number of supply registers.

|

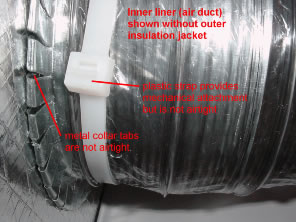

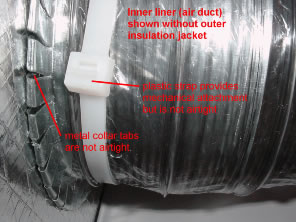

Figure 59 shows how flexible duct connections

typically are made. In some cases metal tape is used, but

the tape wrinkles when applied to complex angles and over

bumps associated with these connection types. Although small

in size, these cumulative wrinkles at each connection allow

air to pass through.

|

|

| Figure

59. Flexible duct to metal collar connection. |

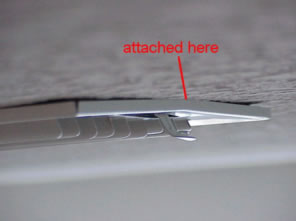

Figure

60. Register to ceiling leakage. |

Computer

Modeling for Florida Energy Code Air Handler Multipliers:

FSEC researchers performed simulations and developed air

handler multipliers for the Florida Energy Code using this

study's simulation results. Researcher used the FSEC 3.0

model, a general building simulation program developed in

1992. This program provided simultaneous detailed simulations

of a whole building system, including energy, moisture, multi-zone

air flows, and air distribution systems.

In

2001, modeling had been performed to develop initial air handler

multipliers. These multipliers were based on estimated Q25

and duct operating pressures. At the time of the 2001 modeling,

there was essentially no data on air handler and connection

leakage. Modeling for this project was performed again, but

this time using the results of the 69 field tested homes.

The

modeling inputs used in 2001 and those from the current study

are shown below. (Please see Table 17.) Note that the same

Q25 and operating depressurization (dP) values

was used for all air handler locations, since there was essentially

no difference between the Q25 values for attic,

garage, and indoor air handler locations when gas furnace

units were removed from the analysis.

| |

2001

Q25 |

AH

Study Q25 |

2001

dP |

AH

Study dP |

| Return

connection |

8.7 |

3.9 |

-40 |

-86.1 |

| AH

- depressurized portion |

48.5 |

17.6 |

-42 |

-139.1 |

| AH

- pressurized portion |

9.6 |

2.8 |

43 |

106.5 |

| Supply

connection |

7.8 |

1.6 |

32 |

58.2 |

| Total |

74.6 |

25.9 |

|

|

Table

17. Air handler (AH) and connection inputs for 2001 and

current project computer modeling.

While

the Q25 leakage for the air handler and connections

was about 65% less than earlier estimates, operating pressures

were much higher. The air handler multipliers based on the

current computer modeling results are presented in Tables

18, 19, and 20. Modeling of air handler energy use also was

performed for the air handlers located outdoors, despite the

fact that no field data was collected for outdoor units.

The modeling input parameters were the same as the other air

handler locations as shown in Table 17. Note also that the

air handler multipliers for the attic, indoors, and outdoors

are normalized to the garage, since this location was considered

the baseline.

| AH Location |

Winter |

Summer |

| old |

2001 |

new |

old |

2001 |

new |

| attic |

1.04 |

1.15 |

1.12 |

1.04 |

1.09 |

1.06 |

| garage |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

| indoors |

0.93 |

0.91 |

0.94 |

0.93 |

0.91 |

0.92 |

| outdoors |

1.03 |

1.08 |

1.06 |

1.03 |

1.03 |

1.01 |

Table

18. Florida Energy Code AH Multipliers for South Florida.

| AH Location |

Winter |

Summer |

| old |

2001 |

new |

old |

2001 |

new |

| attic |

1.04 |

1.11 |

1.08 |

1.04 |

1.10 |

1.08 |

| garage |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

| indoors |

0.93 |

0.92 |

0.94 |

0.93 |

0.90 |

0.92 |

| outdoors |

1.03 |

1.09 |

1.05 |

1.03 |

1.02 |

1.01 |

Table

19. Florida Energy Code AH Multipliers for Central Florida.

| AH Location |

Winter |

Summer |

| old |

2001 |

new |

old |

2001 |

new |

| attic |

1.04 |

1.10 |

1.03 |

1.04 |

1.11 |

1.08 |

| garage |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

| indoors |

0.93 |

0.93 |

0.94 |

0.93 |

0.91 |

0.92 |

| outdoors |

1.03 |

1.07 |

1.02 |

1.03 |

1.02 |

1.01 |

Table

20. Florida Energy Code AH Multipliers for North Florida.

The

final report for this study can be viewed online athttp://www.fsec.ucf.edu/bldg/pubs/cr1357/index.htm.

|