II. BAIHP Technical Assistance H-O

Heat Pipe Technology

Gainesville, Florida

Florida H.E.R.O. met with Chuck Yount, National Sales Manager, and the residential engineering staff to discuss the requirements and anticipated performance of their stand-alone dehumidification system, the BKP series. This system has the ability to provide outside air and maintain positive pressurization, and it can be used in conjunction with a condensing section to reject heat generated through dehumidification. During the 4th budget period, Florida H.E.R.O. suggested the use of this technology to several contractors who build large homes.

HKW

Enterprises

(Lewis Place Association, Ltd., Meadowbrook Development Inc., Millpond

Development Corp., and Joyner Construction.)

Gainesville, Florida

Category B, 333 Homes

Awards: NHBA Energy Value Gold Medal Award

|

Figure 41. Interior

duct system under construction at Lewis Place – the first

Energy Star apartment complex in the country. |

Florida H.E.R.O. worked with HKW Enterprises and its subsidiaries to incorporate Building America specifications in

-

1 apartment complex with 112 units (Lewis Place)

-

2 town house developments with 210 units (Williamsburg and Monticello),

-

1 single family home built by Joyner Construction.

ewis Place was the first Energy Star low income apartment complex in the country and it incorporated an interior duct system (Figure 41) with a comprehensive air sealing protocol that included cellulose wall insulation with a gasket between the top plate and the drywall. The units also featured direct vent gas water heaters for good indoor air quality. The Williamsburg and Millpond townhouse developments and the single family home built by Joyner Construction were built with similar features.

Initial Visit and Testing, Eastern Dakota Housing Alliance (EDHA)

Red Lake Falls, Minnesota

The Eastern Dakota Housing Alliance, a BAIHP partner whose work is further described under Applegren Construction, is considering a partnership with Homark Homes of Red Lake Falls, Minnesota as part of a larger plan to provide affordable housing options in rural areas. Homark Homes is a HUD code and modular manufacturer. BAIHP visited their facility to determine their ability to produce Energy Star level homes. Researchers toured the factory and tested a model home for envelope and duct air tightness.

Construction techniques were consistent with Energy Star level quality and several model specifications are already being produced to Manufactured Housing Research Alliance (MHRA) Energy Star standards. Of special interest was the use of duct and plumbing crossover connections through the rim joist and through-the-wall electrical crossovers, all of which eliminate belly penetrations and their contribution to envelope leakage as is reflected in the ACH50 test result of 3.4. Test results were consistent with Energy Star standards (Table 23).

Table 23. Envelope & Duct

Tightness Test Results

Homark Model 980, dbl section, 1560 sq.ft

| Ducts | CFM25out = 27 Qn = 1.7% |

CFM25total = 210 |

| Envelope | CFM50 = 700 | ACH50 = 3.4 |

A follow-up visit is planned to Homark to certify the plant for production of HUD code Energy Star homes per the MHRA guidelines. This will involve testing at least two more homes and at least three duct systems on the factory floor.

Homes of Merit

Marathon, Florida

Category B, 14 Homes

In 2002, Florida H.E.R.O. performed multiple diagnostic tests and conducted a site survey on a mobile home with mold problems in Marathon, Florida. Florida H.E.R.O. determined that the mechanical system was significantly oversized, and the home was operating under negative pressure during system operation. The owner left the central system fan in the "on" position, further exacerbating the indoor humidity problem. Measured indoor relative humidity levels were about 70%, consistent with outdoor humidity levels. Since this case has gone into litigation, researchers have not had the opportunity to determine the final outcome.

In 2001, Florida H.E.R.O. met with plant personnel and LaSalle Air Systems at Lakeland Homes of Merit factory to discuss Energy Star compliance for model homes and HUD code factories. The researcher also performed duct tests on several models at the Bartow manufacturing plant, assisted in development of material and system specifications, and conducted the Energy Star Energy Star Manufactured Home Plant Certification at the Lake City and Bartow plants.

2005 International Builders Show Showhomes (6th Budget Period)

From January 13 to January 16, 2005, Orlando was host to the 2005 International Builders’ Show, sponsored by National Association of Home Builders. The show was a massive success; the best attended International Builders’ Show on record, with over 105,000 housing professionals in attendances. Located adjacent to the International Builders' Show is an adjunct show, the Show Village.

The Reed Building Group, publishers of Professional Builder, Professional Remodeler, Custom Builder and GIANTS magazines, sponsored the Show Village. The show village is a unique environment where attendees explore showcase homes. Attendees see and learn about products in actual houses, which allows for interaction with manufacturers' products and gives some idea how the products will appear and function in their actual installed environment.

Orlando, Florida

Category A, 1 home

Builder of the New American Show Home for the 2005 National Builders Show in Orlando, Florida. BAIHP supported IBACOS by testing (Table 24) and rating the home and. Data collected at this home by IBACOS will be processed and archived with support from FSEC’s data management system.

Table 24. Test Results for 2005 New American Home

| Test | Measurements | Notes |

| Whole House Air Tightness | CFM50=5552 ACH50=5.0 |

C=549, n=0.591, r=.9996 |

| Duct Leakage AHU1 Master Suite | CFM25,total = 160 CFM25,out = 48 |

3 Ton AHU Flow = 1203 |

| Duct Leakage AHU2 | CFM25,total = 300 CFM25,out = zero |

5 Ton AHU Flow = 1550 |

| Duct Leakage AHU3 Suite 2 | CFM25,total = 104 CFM25,out = 32 |

2 Ton AHU Flow = 898 |

| Duct Leakage AHU4 Foyer | CFM25,total = 155 CFM25,out = 40 |

2 Ton AHU Flow = 1120 |

| All Duct Leakage | CFM25,total = 719 CFM25,out = 120 |

12 Tons AHU Flow = 4771 |

B. Discovery Custom Homes

Modular Showhome

Orlando, Florida

Category A, 1 home

In 2005 the Show Village featured a Discovery Custom home, made by a division of Palm Harbor Homes in their Plant City, Florida factory. The Tuscany model of the Palm Harbor show house is a one-story, three-section, modular factory-crafted home. It has three bedrooms, two bathrooms, and a home office. It has 2084 ft2 of air-conditioned space, a 528-ft2 garage, a 48-ft2 portico, and a 385-ft2-patio deck.

When Palm Harbor was presented with this opportunity to showcase one of their homes, they solicited help from BAIHP to showcase energy efficiency, good indoor air quality, and green building practices. Features incorporated into the home are:

Energy Features

-

Unvented structurally insulated panel (SIP) roof over master bedroom and hearth rooms

-

R-33 vented ceiling over first two sections

-

Conditioned, unvented insulated crawlspace

-

Low-E Argon metal windows U=.47, SHGC=.32

-

R-22 walls

-

SEER 17.95/ HSPF 7.95 two-speed compressor right-sized heat pump, programmable thermostat with outdoor thermostat which prevents strip heat turn-on above freezing

-

Instantaneous propane water heater

-

Compact fluorescent lights in selected areas

-

Energy Star Appliances

-

Estimated energy savings = 35% on a whole house basis

-

Home Energy Rating Scale (HERS ‘99) Score = 93 Out of 100

Indoor Air Quality Features

-

Fresh air ventilation with filter on outside air intake (fresh air is provided only when the air handler unit is on)

-

Humidistat (built-in with thermostat)

-

MERV9 media filter with 3500-hour life

-

Ultra-violet A lights with catalyst to reduce volatile organic compounds

-

Low VOC materials and VOC Source Control

Green Building Features

-

Enhanced indoor air quality and energy efficiency

-

Resource efficient construction and construction waste management

-

Water efficient appliances and fixtures

-

Durable, low maintenance design

-

Meets Florida Green Building Coalition standards

After the show, the home will be donated to Orlando's Home Builders Association's Foundation. Palm Harbor is the 2001 Gold Award winner of the National Housing Quality Award.

Orlando, Florida

Category A, 1 home

Sarah Susanka Not So Big Showhouse for the 2005 Builders show. (Figure42) FSEC assisted CARB with the HVAC system design. FSEC tested the air tightness of the ducts and the envelope, assisted in the design and installation of the PV and solar water heater, performed the Energy Star and FGBC certifications.

|

Figure 42. Not So Big showhouse in Orlando, FL. |

The home’s energy saving features which were selected with the hot-humid Florida climate in mind, include:

-

High efficiency air conditioning (SEER 16)

-

Active dehumidification and ventilation

-

Solar water heating with tankless gas backup

-

High performance glazing

-

Reflective metal roofing

FSEC installed instrumentation and data was regularly collected and displayed on an InfoMonitors website. The measured energy was used to determine if the energy features are working out as planned and in InfoMonitors web-site was developed.. More info at http://www.notsobigshowhouse.com/

-

Comfort conditions (temperature and relative humidity)

-

Total energy use

-

Detailed data on cooling, heating, and water heating energy use (the three main energy users in American homes)

After the show was over, conversations continued with the new owner of the NSBSH and a site visit was made by BAIHP researchers to review all the features of the home. There were some issues regarding the electrical service entrance panel where wires were not properly insulated and a short had occurred. The homeowner contacted the builder to resolve the issue. The DC disconnect for the PV system was never installed and the homeowner was informed of this. The solar water heating system was not operating properly at the time of the site visit and it appeared that the DC circulation pump had failed or a connection was damaged. The homeowner agreed to contact the installer for assistance.

2006 International Builders Show Showhomes

A. New American

Home

Orlando, Florida

Category A, 1 home

BAIHP supported IBACOS – the primary technical assistance provider for the annual New America Home – by making site visits to document progress in the months leading up to the 2006 IBS. During construction, pictures were taken on a bi-monthly basis and made available for public view. The home achieved a Florida Energy Star rating of 90.8.

Green building and energy star certifications were awarded to Hannigan Homes for the New American Home 2007. The presentation was conducted during a press event at the home during the 2006 International Builders Show.

NextGen Show Home; First Time Show Home, and Move-Up Show Home

Orlando, Florida

Category A, 2 houses

Category B, 1 house

FSEC personnel provided design input and made several visits to Palm Harbor Home’s Plant City manufacturing and sales facility to inspect and test prototypes of the three show homes for the 2006 IBS show. Recommendations to improve the air distribution system and HVAC installation were made to help PHH meet the FGBC guidelines and Building America levels of energy efficiency for all three houses.

In December 2005 the houses were evaluated in both Energy Gauge Florida and USA, as well as evaluated for compliance with Florida’s Green Building Program. Of the three homes, the NextGen home met the Green Standards, and the other two needed only simple improvements to meet the Green Home standard which were made. The NextGen house was built to the Institute for Business and Home Safety’s Fortified Home standard to further enhance Palm Harbor’s already outstanding durability and wind resistance.

In January 2006 before the show, all three homes were inspected, tested and certified as Florida Energy Star compliant and qualified for the Florida Green Building Coalition Green Home Certification. The December 2005 energy and green recommendations were followed, resulting in homes that met the Building America HERS ‘99 rating of 90+ except the Move-Up house, which had duct work problems in the field which prevented it achieving a HERS ‘99 score of over 89.6. (Table 25)

Table 25. 2006 IBS Palm Harbor Homes HERS ‘99 scores

Model |

HERS ‘99

Score |

NextGen |

90.6 |

Move-Up |

89.6 |

First Time |

90.0 |

One-page BA summaries of each Palm Harbor Homes Showhouses were written and framed Energy Star and Green Home certificates made for display in each model.

Preparations for the 2007 IBS began early in 2006. Meetings were held with representatives from Schneider Electric (Square D), Sharp Electronics, Fronius USA (solar inverter manufacturer), DOE, and many other show participants. Schneider Electric announced a new Intelligent Load Center with an automatic disconnect to backup power sources such as generators and PV systems for distributed generator–ready homes. The load center is estimated to save $800 to $1200 in product and labor costs.

BAIHP will again support IBACOS in this project and during the final year of the project, construction progress is being documented with weekly pictures at the FSEC website, available for public viewing.

On February 2 BAIHP met with representatives from the Kashi Church Foundation located in Sebastian, Florida. This group oversees a private development which is expanding through construction of new residential housing. Preliminary discussions were held regarding green certification and a Building America partnership. The Building America partnership was initiated in early 2006 to assist with the design and construction of 33 new homes.

Caldwell, Idaho

See also “Zero Energy Manufactured Home” in the Research section of the report.

Kit Home Builders West was the builders of the Zero Energy Manufactured Home in response to an RFP issued by the Bonneville Power Authority in partnership with BAIHP staff in Washington and Idaho. See Zero Energy Manufactured Home in the Research section of this publication.

|

Figure 43a. Kokanee Creek

HUD-code Multi-Story HUD-code housing |

Marlette

Homes, Kokanee Creek

Everett, Washington

In 2004, Marlette was involved with a new 32 home multi-story development called Kokanee Creek (Figure 43a). BAIHP staff conducted field evaluation on the first set of homes and provided technical assistance to Marlette and the developer HomeSight, related to the envelope and duct leakage improvements. This was a follow-up project to the successful collaboration with Marlette Homes in the NOGI Gardens community.

|

Figure 43b. Nogi Gardens, America's

first HUD Code attached town houses. |

Marlette

Homes, NOGI Gardens

Seattle, Washington

Technical Assistance by BAIHP Contractors Washington State University

Energy Program, Oregon Office of Energy and Idaho Department of Water Resources,

Energy Division

Awards: HUD Secretary’s Gold Award for Excellence

Energy

Value Housing Award

Nogi Gardens is a 75-home community located in southeast Seattle The project contains the first two-story, HUD Code attached “townhouse homes” (Figure 43b). All the homes have been built by Marlette Homes in Hermiston, OR to Super Good Cents/Energy Star specifications. A blower door test of the building envelope showed 5.0 ACH at 50PA, average for a manufactured home in the Pacific Northwest. Duct leakage is very low, due to Marlette’s use of mastic and duct risers.

Miami (Dade County), Florida

Technical Assistance by BAIHP Researchers Rob Vieira and Eric Martin

This project was a community revitalization program aimed at lessening poverty density by demolishing dilapidated public housing and replacing it with new, less dense housing. In this HUD-sponsored inner city redevelopment project, about 860 public housing units were to be torn down and replaced with 450 new units. The new units would have included duplexes, townhouses, and single-family homes.

As part of a sustainability team, FSEC participated in the initial design charrette which reviewed project home designs, made architectural recommendations on wall and roof assemblies, exterior finishes, and other energy-related design and construction features.

During 2002, FSEC provided assistance to Miami-Dade Department of Environmental Resources Management when they emphasized the importance of Building America principles and techniques to the Miami-Dade Housing Authority. The Housing Authority conducted a mandatory value-engineering meeting to ensure that their Hope VI Project would meet the available budget. FSEC staff, as well as other stakeholders, took part in housing discussions and analysis to ensure that the Building America principles and techniques specified early in the project would be considered and not engineered out of the project.

Unfortunately, this project never got past the design stage due to a lack of cooperation among existing residents of the area.

Three SGC homes were built at the Nez Perce tribal fish facility in Cle Elum, WA. One of these homes is equipped with Energy Star appliances and lighting; all three homes are heated with Insider heat pumps. Monitoring equipment was installed in Year 2. In Year 3, preliminary blower door testing indicated a high leakage rate. During Year 4, tests found significant duct leakage due to failure of butyl tape at risers on 2 year old home. (See also Section III Research Zero Energy Manufactured Home.)

Ft. Myers, FL

Category B: 1 house

|

Figure 44. New Generation Home |

Idaho, Oregon, and Washington (State)

(See also Champion Homes and Fort Lewis Military Housing)

The Washington State University Energy Program (WSU), together with partners Oregon Office of Energy and Idaho Department of Water Resources, Energy Division, continue to provide technical and research support to the Northwest Energy Efficient Manufactured (NEEM) Housing Program in the Pacific Northwest. The NEEM program involves 20 plants in three states, hundreds of retailers and thousands of homebuyers.

The NEEM program includes the brands Super Good Cents and ENERGY STAR, and includes homes heated by electricity and Natural Gas/propane. Prior to 2003, the NEEM program also included the Natural Choice brand, which was exclusive to homes heated with Natural Gas or propane. In 2003, the Natural Choice brand was phased out; now, all gas heated homes are branded ENERGY STAR. In 2004, a new path for ENERGY STAR was developed for Super Good Cents homes with electric furnaces. Homes will be built to this path beginning in 2005.

In the fall of 2004, NEEM staff began to provide technical assistance to Champion Homes on an 850 unit private military modular housing development at Ft. Lewis. In-plant verification, certification and on-site verification of these homes began in spring of 2005 and continues as a major BAIHP effort. (See Champion Homes in Technical Assistance.)

In the fall of 2004, technical assistance by NEEM staff to the Energy Trust of Oregon resulted in the development of a million dollar utility incentive program that promotes the production of a more NEEM homes built to higher benchmarking levels consistent with BAIHP goals. A technical analysis of the ETO program has been provided to FSEC.

Aligning with New Building America Goal

In the summer of 2004, BAIHP staff performed a benchmarking evaluation

to assess the improvement of NEEM homes over the entire BAIHP project

period (note that this evaluation was included in the Year 5 (April

2003 – March 2004) annual report). The benchmarking was based

on a home defined by NREL (built to IECC requirements). The savings

over the benchmark home were estimated using version 2.2 of Energy

Gauge USA. Evaluations were performed for a typical 1600 ft2 double

wide home with 12% glazing to floor area (the NEEM fleet average) in

three Pacific Northwest climate zones: Portland, OR; Spokane, WA; and

Missoula MT.

The homes were benchmarked assuming a continuously operating whole house ventilation system, resulting in a significant thermal energy penalty. Additional benchmarking was also conducted using the 164 kWh/year ventilation assumption in the NREL benchmark, in an effort not to penalize the homes for improved IAQ associated with HUD whole house ventilation system requirements and ASHRAE 62.2.

In 2004-2005, improvements were made to NEEM HVAC systems and duct specifications as a result of BAIHP research (see Refinement of NEEM Specifications, below.) Additional benchmarking is presented that reflects these improvements.

The results of the benchmarking vary considerably by HVAC type, water heat and climate, as noted in Table 26 below. Some key observations:

-

In all climate zones, electric homes result in negative savings if the ventilation penalty is assumed. This is largely the result of the assumption that the benchmark home has a heat pump that performs without installation problems; an assumption that will be evaluated by BAIHP research.

-

Gas heated NEEM homes came closest to meeting the overall BAIHP goal of 40% over the NREL benchmark, but only met the goal if gas heat is paired with electric water heat, in cold climates with no ventilation system penalty.

-

Eliminating the ventilation system penalty has a higher impact on benchmarking results (9 to 23 percentage points) than improved duct leakage tightness (3 to 11 percentage points).

-

It should be noted that Benchmarking these NEEM homes against the HUD-FMCSS requirements (Uo=.079) for manufactured homes rather than the IECC (Uo=0.06) would yield considerably higher savings than current benchmark assumptions.

Table 26. Benchmarking Savings Results

| Duct Leakage | Pre-2004* |

2004** |

Pre-2004* |

2004** |

| Ventilation System Penalty | Yes |

Yes |

No |

No |

| Portland | ||||

| Electric Furnace | -31 |

-20 |

-8 |

0 |

| Heat Pump | 11 |

14 |

20 |

22 |

| Gas Heat/Elec DHW | 16 |

22 |

32 |

37 |

| Gas Heat/Gas DHW | 15 |

20 |

30 |

34 |

| Spokane | ||||

| Electric Furnace | -18 |

-9 |

2 |

10 |

| Heat Pump | 17 |

21 |

27 |

30 |

| Gas Heat/Elec DHW | 22 |

27 |

36 |

41 |

| Gas Heat/Gas DHW | 21 |

26 |

35 |

39 |

| Missoula | ||||

| Electric Furnace | -12 |

-3 |

8 |

15 |

| Heat Pump | 17 |

22 |

28 |

32 |

| Gas Heat/Elec DHW | 21 |

26 |

35 |

40 |

| Gas Heat/Gas DHW | 20 |

25 |

34 |

38 |

*

Pre-2004 – Duct

leakage of -132 cfm@25PA ** 2004 – Duct leakage of -60 cfm@25PA |

||||

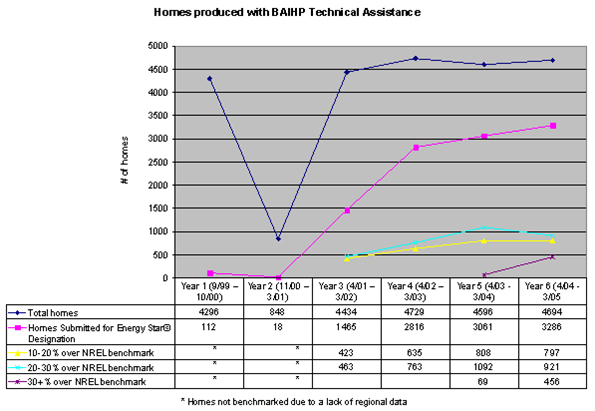

Figure 45 shows, by program year, the number of homes produced with technical assistance from BAIHP, as well as the number of homes submitted for ENERGY STAR designation by BAIHP staff and the breakdown of homes by benchmarking score. Please note the following:

-

The benchmarking includes the assumption, based on the NEEM 5th Budget Period random that showed 24% of all homes included after-market heat pumps.

-

No benchmarking was performed for Years 1 and 2, due to a lack of accurate regional data.

-

In 2003 and 2004, the appearance of homes that achieved a 30+% benchmark is the result of the improvements made to the NEEM HVAC specifications.

-

Figure 45 averages benchmarks for Spokane and Missoula for homes in cold climates and uses the Portland benchmark for marine climates. Figure 45 also assumes an average value between ventilation penalty and no ventilation penalty.

The continued success of the program is due to several factors. BAIHP and NEEM staff worked to increase awareness within the manufactured housing industry of the marketing value of energy efficiency, increase participation by utilities in incentive programs, and promote the co-branding of NEEM with ENERGY STAR.

Figure 45. Homes Produced with BAIHP Technical Assistance

The increase in ENERGY STAR designations is due to refinement of the SGC duct sealing specifications, resolving a discrepancy between the SGC specifications with ENERGY STAR’s duct sealing protocols (while this question was being resolved September of 1999 through early 2001, BAIHP staff did not submit homes to DOE for ENERGY STAR designation). In 2003, remaining discrepancies with manufacturers in Idaho were further resolved, allowing BAIHP staff to accurately report all qualifying homes.

NEEM Refinement of SGC specifications

BAIHP staff continually work to refine the existing SGC specifications,

a result in large part to innovative building technologies researched

in BAIHP.

In 2003, BAIHP staff worked with NEEM staff and manufacturers to develop revisions to NEEM specifications, including allowing only mastic for duct sealing, requiring metal flex duct for whole house ventilation fans, and changing the air infiltration specification from 7.0 ACH50 to 5.0 ACH50.

The revised specifications were voted on and accepted by the manufacturers; they took effect on January 1, 2004.

In year 2004 in Oregon and Idaho plants began testing the ducts in all the NEEM homes they produce, which is expected to result in even tighter duct systems. Field testing of a sub-sample of these homes duct testing began in 2004 and continues. This field testing is also evaluating homes that employed a “thru-rim” crossover duct system.

BAIHP staff continues to work with EPA and other regional partners on clarifying the equivalency of SGC with ENERGY STAR. In 2002, BAIHP staff developed a new ENERGY STAR compliance path for climate zone 2 that does not require a heat pump. The non-heat pump path uses a heat recovery ventilation system, a .93 EF hot water heater and tighter ducts and envelope. This path was not utilized due to reluctance by manufacturers to install HRV systems. In 2004, this path was modified to eliminate the HRV, and include options such as set-back T-stats, ENERGY STAR dishwasher, adjusted glazing limits, improved window U-factors, and in-plant tested duct systems.

NEEM Revised In-plant Manual

In 2003, in light of the revisions to the NEEM specifications, BAIHP

staff from the Oregon Department of Energy developed an updated in-plant

inspection manual, with new graphics, including details on correct

installation of heat recovery ventilation. Many of the manual updates

are the result of BAIHP research and demonstration efforts, including

use of hybrid floor systems and proper duct sealing with mastic. The

manual also now includes a regionally consistent problem home inspection

protocol.

NEEM In-plant QC Training

In 2004, BAIHP staff from the Oregon Department of Energy developed a

PowerPoint presentation, based on the revised In-plant manual. In 2004,

BAIHP staff began using this presentation to train QA staff at each

plant; this effort will continue until all NEEM plants have received

this training.

NEEM In-Plant Inspections

On a quarterly basis, BAIHP staff visits each of the manufactured housing

plants to verify compliance with SGC/E-Star specifications. Inspections

include a plant audit, ventilation system testing, and troubleshooting

construction-related problems with plant staff and independent inspectors.

Consistent issues in the plant include wall insulation compression

or voids due to improper cutting of batts, attention to duct installation

and air sealing. Specific in-plant inspection reports conducted in

Washington in program Year 6 (March 2004 – April 2005) are provided

to FSEC.

NEEM Manufacturers’ Transition to Mastic

As mentioned above, the NEEM program eliminated the use of butyl tape

for duct sealing, and required the use of mastic. By the spring 2004

(year 6), ten manufacturers have successfully transitioned to mastic.

Testing in-plant has indicated significant improvement in duct leakage

rates of homes in these factories– an average 36.8 cfm @ 25 PA

(versus 50.1 cfm @ 25 PA pre-mastic), a 27% improvement. This trend

continued into 2005.

Also in the 6th budget period, WSU and ODOE began working with Fleetwood engineers to evaluate a new lower cost duct leakage testing device that Fleetwood is considering using in all of its plants throughout the USA. The preliminary results suggested a need utilize 10 second averaging and set a higher pressure ratio from 86% to 90% to be consistent with NEEM duct leakage targets. This work will continue through program 2005-06.

In the final year of the project, thirty homes built by manufacturers with the most experience using mastic and in-plant duct leakage testing were tested to represent the highest efficiency ducts achievable by the improved 2004 NEEM specifications. These “best case” ducts were compared with previous random sample BAIHP research of NEEM homes that used butyl and acrylic foil tape. In addition, researchers conducted field and modeling assessment of the energy impacts and implementation challenges of through-rim crossover duct systems. The report of these findings will be published as part of the HUD-code Symposium at the ASHRAE 2007 Winter Meeting.

NEEM Duct Testing Workshops

Through the spring of 2005, BAIHP staff continued to provide workshops

focused on improved duct installation and inspection oversight, working

in partnership with BAIHP partners. One in-plant duct leakage workshop

resulted in the identification of significant duct leakage (branch

disconnect) which re-enforced the need to consider duct testing of

all units at that plant.

Since January of 2006, all 10 Oregon factories, four out of five Idaho plants, and one out of two Washington plants test all duct systems in each floor to ensure low leakage ducts using testing equipment – very good progress in a two year period.

NEEM New Technology Evaluations

|

Figure 46. 90% AFUE Furnace,

as installed at Kokanee Creek |

High Efficiency Gas Furnaces Initial evaluations of 90% efficient gas furnaces indicates that there is no incremental installation cost to the use of these furnaces, as no field modifications are required. In 2003, Nordyne and Evcon came out with furnaces with an appropriate footprint for manufactured housing; Intertherm also continues to offer a 90% efficient model. Discussion with BAIHP home manufacturer partners Fuqua, Marlette, Champion, and Fleetwood, and furnace manufacturer partners Evcon and Nordyne, indicate the that this market is growing quickly, especially in homes with high pitch “tilt-up” roof systems, and multi-story homes such as the ones at Nogi Gardens and Kokanee Creek. The ability to use wall venting instead of roof venting with condensing furnaces makes them more attractive where tilt-up roofs are employed.

Through the rim crossover duct system Three Oregon manufacturers,

Marlette, Skyline and Homebuilders Northwest, adopted a crossover duct

system that runs through a cut out section of the rim joist, effectively

placing the entire crossover system in the heated space. A gasket on

the marriage line provides a seal between sections. Challenges with the

use of this system include the need for very accurate measurements to

insure matching of the duct connection, and careful treatment of the

gasket material during set up, so that it doesn’t detach from the

rim.

Evaluations suggest that that further improvement to gasket systems may

be needed to ensure set-up that achieves effective duct sealing.

La Salle Duct Riser BAIHP staff worked with BAIHP partner La Salle

Air to design and produce a duct riser for manufactured homes that uses mastic

instead of tape. BAIHP staff demonstrated prototype designs of the riser to

Northwest manufacturers in year 3. Most NEEM manufacturers adopted the new

risers or equivalent systems in year 6. BAIHP staff worked with Fleetwood’s

national office to promote the use of the riser in all Fleetwood plants. During

2003-2004, BAIHP staff promoted the use of this technology at the annual MHI

conferences and energy road-mapping meetings.

Figure 47. Insider Heat

Pump in ZEMH and Base Home –

Operation in HP and Strip Heat Mode

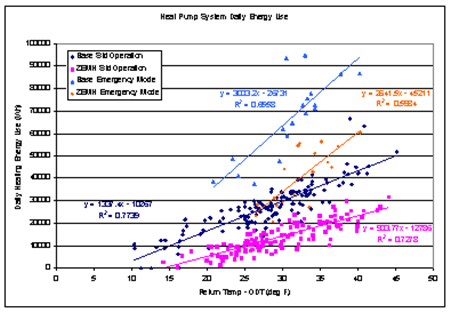

Insider Heat Pump: Monitoring of the Insider heat pump at the WSU Energy House was begun in 1999. Measured flow rate of the indoor unit was good (850 CFM total, 425 CFM per ton), but BAIHP staff identified two performance issues: a too-frequent operation of the defrost cycle and a lower than expected airflow at the outdoor coil. Continued testing of the Insider in 2002 indicated a 10% increase in COP due to increased airflow at the outdoor coil. At Vincent Village, the property manager indicated a high degree of satisfaction with the Insider heat pumps, with no comfort complaints. Flip flop testing that varies the compressor and electric resistance heat was conducted in the WSU and ZEMH. The results of those tests being analyzed for an ASHRAE paper to be submitted in 2005. The Insider Flip flop test results are presented in Figure 47.

Energy Conservatory Products: BAIHP staff work with the Energy Conservancy (EC) to evaluate their new products for measuring air handler and exhaust fan flows. In 2004, BAIHP staff worked with EC staff to develop an automated test that will provide duct leakage to outside. Discussion with EC indicated significantly increased sales of duct blasters to HUD-code manufacturers as a result of BAIHP efforts. WSU continues to work with EC to develop new building science tools for HUD-code housing.

NEEM Work with Other Technologies: In 2004, BAIHP staff submitted a status report summarizing program efforts to introduce BAIHP manufacturers to new technologies. The report highlights the barriers and successes made regarding:

-

24” OC Wall Framing

-

Air-Tight Can Lighting Fixtures

-

Solar Ready design

-

Improved flashing/drainage systems

-

High Efficiency Water Heaters

-

Blown Cellulose Hybrid Floor Insulation

-

Condensing Gas Furnaces

-

Heat Pump Water Heaters – Site built

-

Hi-R wall Systems (Foam Sheathing + Icynene) – Site Built

Moultrie, Georgia

Hillsboro, Texas

Kileen, Texas

Technical Support by BAIHP Researcher David Beal

BAIHP assisted Oakwood Homes with one problem home investigation between April 2003 and March 2004. This large HUD code manufacturer previously requested an FSEC duct installation review and consultation on ways to make the home’s systems work better together. In 2002, plant visits were made to the Oakwood plant in Moultrie, Georgia and to the Hillsboro and Kileen, Texas plants. Recommendations for appropriate duct system design and manufacture were reported to Oakwood Homes.

An EnergyGauge USA analysis of Energy Star and non-Energy Star homes in Boston, Minneapolis, and Indianapolis was performed. Researchers determined that Oakwood Homes could meet Energy Star standards if they increased installed gas heating and cooling system efficiencies, and floor and roof insulation levels. These results were communicated to Oakwood management via email.

BAIHP Home | Overview | Case Studies | Current Data

Partners | Presentations | Publications | Researchers | Contact Us

Copyright © 2002 Florida Solar Energy Center. All Rights Reserved.

Please address questions and comments regarding this web page to BAIHP Master