II. BAIHP Technical Assistance B-D

Bellview Air

Gainesville, Florida

Florida H.E.R.O. discussed a range of issues with Bellview Air, including the impact of input data on Manual J equipment sizing and the air handler location in an effort to improve indoor air quality, comfort, and energy performance. The potential benefits of unvented cathedralized roof systems were also addressed.

Bobek Building Systems

Oviedo, Florida

|

Figure 9. 1800 sq.ft. Steel Frame

Residence near Oviedo, Florida |

BAIHP conducted a testing visit to new BAIHP partner. Bobek Building Systems building exclusively with steel frame and partial panelized construction (Figure 9) to measure whole house and duct leakage and to evaluate envelope insulation with IR camera. BAIHP compiled the results of the testing and sent design recommendations to the builder.

Table 11. Air Tightness Testing

| Blower Door Test Results | Duct System Air tightness |

| CFM50 = 1693 | CFM25total = 285 |

| ACH50 = 7.05 | CFM25out = 42 |

| C=157.8, n=0.607, r2=0.999 | Qn = 2.3% |

Duct testing shows low leakage to out (2.3%) but an excessive level of total leakage. The ducts are located in the attic which is largely sealed (essentially unvented) with an insulated steel panel roof deck. During blower door testing, the attic space was found to depressurize to 13 Pascals while the home was at -50 Pascals, showing the space is better connected to the conditioned space than to the outside. One known area of attic leakage to outdoors occurs at the front porch overhang.

The high total duct leakage should be addressed to ensure proper distribution and mixing. In many cases this is caused by leakage where the supply register ties into the supply boot. Supply registers with integral foam seals are recommended to provide a tight fit at the boot connection and where the register meets the ceiling surface.

Infrared Imaging

|

Figure 10. Thermal Image of Exterior,

Steel-framed Walls |

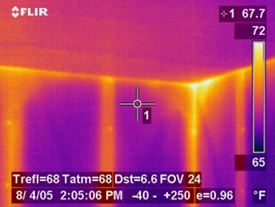

The IR picture in Figure 10 shows a corner, side and front wall from inside the home. This picture is typical of IR images from inside the house perimeter. Portions of the wall shown violet in color reflect an indoor temperature of approximately 67º. Lighter and brighter colors indicate higher temperatures. Metal studs and points of joining between the ceiling and side walls can be seen in orange and light yellow.

As can be seen from the IR picture, thermal shorts exist between the outdoor and interior space. Though the overall differential between room temperature and stud temperature is relatively small (5ºF), the cumulative effect may represent a significant conduction load on the space conditioning system. Reducing thermal bridging between outside and inside the home will reduce thermal loading taking place inside the home. This, in turn, will reduce air conditioning run times.

BAIHP Recommendations included:

-

Sealed supply and return registers to reduce total duct leakage and improve distribution efficiency

-

More attention to sealing the attic space from outdoors since this is essentially a buffer to the conditioned interior space. This will also lessen any duct leakage to outdoors.

Additionally, some method of breaking the thermal short between the stud and the back of the drywall should be deployed in future construction efforts. Consideration should be given to applying foam board, ¾” minimum, between the stud and the drywall. At a minimum, application of adhesive backed foam strips applied to the stud prior to drywall installation should be considered.

Cambridge Homes

Orlando, Florida

Category B, 1 Home

Note 100% Energy Star Builder

|

Figure 11. The Augusta, Cambridge

Homes BA Prototype |

This BAIHP partnership resulted in continuation of monitored field research in the Augusta Building America model (Figure 11) and a control home. See BAIHP Research (Section III), Site Built Housing Research, Cambridge Homes.

In November 2004, BAIHP participated in a meeting with this partner to discuss water damage incurred in recently built homes as a result of the 2004 active hurricane season. Approximately 12 people took part in the meeting including BAIHP researchers, and Cambridge Homes design, construction, and architecture personnel. Results of field investigations were shared, and potential solutions discussed.

Papers: Mullens, M., & Chasar, D. (2002). “Energy Test Results and Recommendations for Cardinal Homes.” University of Central Florida Housing Constructability Lab BAIHP Report, Cocoa, FL.

During the 4th budget period in cooperation with the University of Central Florida Industrial Engineering Department (UCFIE), FSEC researchers tested four Cardinal modular homes with the Cardinal sales manager and plant quality engineer. Initial results found that peak loads for heating were almost double that for cooling. All four of the homes had leaky ducts. These leaks accounted for the largest peak load in the homes, averaging 28% of the winter peak and 21% of the summer peak.

Windermere, Oakland/Winter Garden, Florida

In early 2006, BAIHP researchers met with builder, developer, and architectural representatives from Castle & Cooke, a development group planning a new community called Oakland Park located in Orlando Florida. Work is underway to assist with the systems engineering of a residential building that is to act as a sales center/office before it is sold as housing. Building America principles will also be extended to the rest of the approximately 500 homes located in the development.

Champion Homes, see also “Fort

Lewis Base Housing”

Washington (state)

Category B, 160+ homes

Papers: Baechler,

M.; Lubliner, M; Gordon, A (2002). “Pushing the Envelope: A Case

Study of Building the First Manufactured Home Using Structural Insulated

Panels” 2002 ACEEE Summer Study on Energy Efficiency in Buildings

Conference, American Council on an Energy Efficient Economy, Washington,

DC, August 2002.

Also see Fort Lewis Case Study in the Building America Marine Climate

Best Practice Guide

In 2000 Champion Homes built the first stress skin insulated panel (SIP) manufactured home now sited in western Washington. The house air tightness was measured at ACH50=3.55, well below the average numbers for all homes previously tested in the WSU random home study (see Northwest Energy Efficient Manufactured Homes). Energy savings are estimated at 50% greater than a home constructed to the HUD Code. These results were presented at the 2002 ACEEE Summer Study, authored by Pacific Northwest National Laboratory (PNNL), and BAIHP staff and partners.

In 2004 Champion Homes was chosen by Equity Properties to provide house components for up to r 850 modular homes to be used as base housing at Fort Lewis Army Base also in western Washington State. Equity made the decision to use modular due to the large number of unit going up at one time, and significantly drier conditions inside the factory to minimize moisture and mold damage during construction.

While QA indicates that duct leakage protocols are being implemented well, WSU staff is continuing to work with Champion, Equity Consulting (the developer) and Oregon Department of Energy in plant QA staff assess issues associated with attic insulation levels, HVAC, DHW and lighting system, .

By November of 2005, 64 homes had been ENERGY STAR certified, with an anticipated build out of 70 additional homes for the rest of the year. Results indicate that duct leakage protocols are being implemented well, but issues of attic insulation need to be addressed. WSU, ODOE, Equity and Champion working with PNNL recently completed a Ft. Lewis case study, which is feature in the Building America Marine Climate Best Practice Guide.

As of June 2006 over 160 homes have been completed and certified as Energy Star.

Plans are underway in 2006 to implement HVAC research with Building America partner Carrier Aeroseal™ on a tri-plex test building. These plans include the installation of a 94% AFUE furnace with ECM motors, and the Aeroseal™ duct leakage/testing system. A utility analysis is planned to compare gas and electric bills in these homes to the larger sample of identical of homes at Ft. Lewis.

City of Gainesville

- Cedar Grove II

Gainesville, Florida

Category B, 139 Homes

Award: HUD award for Innovation

in Housing in 2004

|

Figure 12. City of Gainesville house

in Cedar Grove II |

Florida H.E.R.O. began working with the City of Gainesville before the ground-breaking in the Cedar Grove II subdivision of HUD housing. Project manager Judy Raymond envisioned a new urban style development (HUD’s first) with single family homes featuring high quality construction and individualized character with front porches and front façade details (Figure 12). She worked with Florida H.E.R.O. to develop engineered plans for mechanical and air distribution systems and a whole house package that was recognized with a HUD award in 2004. Table 12 summarizes the specifications.

Table 12. City of Gainesville, Cedar Grove II Subdivision, HUD Home

| Component | Specification |

| Conditioned Area | ~1200-1400 (139 units) |

| HERS ‘99 Rating | 86-88 (goal = 86) |

| Cooling And Heating | SEER 12 with hydronic heating; some 80% AFUE furnaces with programmable thermostat. |

| Duct System | Ducts in conditioned space. Ducts

moved to attic in later phase. Return duct and air handler

still conditioned space. Duct system engineered using Manual D, sealed with mastic, all homes performance tested for duct air tightness. CFM25out≈25 |

| System Capacity | Cooling and heating systems sized using Manual J calculation procedure |

| Walls | R-13 cellulose |

| Ceiling | R-30 cellulose insulation with radiant barrier |

| Windows | Double pane metal frame |

City of Orlando, The Orlando

House

Orlando, Florida

Category A, 1 House

|

Figure 13 The Orlando House |

The City of Orlando, through the office of Housing and Community Development in the Planning and Development Department, constructed an environmentally friendly demonstration home called The Orlando House: Florida’s Future, on an infill site within the city (Figure 13). The City requested FSEC assistance to assure the home met Building America goals and the Florida Green Home Designation Standards. Ground broke on the demonstration home in December 2001 and the home was open to the public for community education purposes for approximately one year. Specifications are listed in Table 13.

The City acquired more than $100,000 in donated materials and services for the project, and completed much of the construction using their own staff. Along with public education, a primary purpose for this project was to give the city staff first hand experience in the use of green building materials and techniques - especially those relating to energy efficiency, indoor air quality, durability, disaster mitigation, and termite resistance. That experience would allow the products and techniques to be effectively used in future low-income housing constructed by the city.

One particular focus of this project was disaster resistance. For protection from wind storms, a durable steel structure was used along with a safe room located in the detached garage. For termite resistance, all structural and exterior finish materials were selected on the basis of providing the least amount of available food source. Materials such as borate treated lumber and sheathing, steel structural components, and plastic/composite finishes were used extensively in conjunction with a Termi-mesh barrier system.

FSEC certified the house for the Florida Green Home Designation Standard in February 2003. FSEC staff also presented information regarding Florida Green Home Designation as part of a builder training event held at the Orlando House. Two CEUs were available to attendees, and approx. 30 people attended from the central Florida area. Training also included talks on Zero Energy Homes, Florida Sun Built Program, and a “builder panel” that included 3 BAIHP partner builders.

The demonstration home was sold in May 2003, and money acquired from the sale will go directly towards the construction of low income housing that utilizes several green building techniques.

Table 13. City of Orlando – Orlando House

| Component | Specifications |

| Conditioned Area | 2148 sq. ft. |

| HERS ‘99 Score | 88.3 |

| Envelope | |

| Above-grade Wall Structure | Steel Frame 1st and 2nd floors |

| Above-grade Wall Insulation | R-19 Icynene |

| Exterior Wall and Roof Sheathing | OSB - Borate treated |

| Attic | Unvented R-19 Icynene |

| Roof | Metal |

| Windows | Double pane Low-E |

| Equipment | |

| Heating & Cooling | 13 SEER heat pump |

| Thermostat | Programmable |

| Ventilation | Passive outside air vent |

| Water Heater | 50 gal, EF=0.88 (Electric) |

| Lighting | 100% fluorescent |

| Appliances | Energy Star |

Additional Green Features:

|

|

|

Figure 14. Low income housing

built by the City of Lubbock using insulated concrete forms. |

Through the Portland Cement Association (PCA), contact was established with the City of Lubbock who is building low income houses with insulated concrete form (ICF) systems (Figure 14). FSEC researchers visited Lubbock twice to conduct diagnostic tests and provide training and technical assistance. FSEC also conducted initial HERS ‘99 ratings on four Lubbock Habitat for Humanity (see Habitat for Humanity, Texas) homes plans and introduced the Habitat affiliate to the City of Lubbock’s other low-income housing activities.

Clayton Homes

Waycross, Georgia

FSEC personnel conducted a plant visit of the Clayton Homes factory in Waycross, Georgia in June 2002. A singlewide home was tested and observations recorded of home and duct construction techniques. Findings and remedies for leaky ducts found during the visit were reported to factory representatives in a follow-up trip report.

|

Figure 15. Completed Dukane Precast

home tested by BAIHP |

FSEC made a February 2002 site visit to Dukane Precast in Naperville, Illinois and provided technical design assistance in a follow-up telephone conference call in March ‘02.

In 2003, Dukane Precast requested BAIHP assistance in the design phase and monitoring of the first prototype of a new line of homes called “The Fortified House” (Figure 15). Objectives of Dukane’s Fortified House include energy efficiency, comfort, durability, and good indoor environment conditions.

In December 2003, FSEC visited 3 prototype buildings in various stages of construction in. One was complete. Researchers made recommendations regarding window flashing, below grade drainage and waterproofing, interior ducts, air sealing, attic access detail, floor finishes with radiant heating, radiant heat zoning, ventilation system design and operation.

In February, FSEC returned to Dukane for testing and infrared evaluation of 3 completed prototype Fortified Homes built by Dukane’s sister company, Mustang Construction at Keller Court, Boilingbrook, IL, just west of Chicago.

Infrared images were recorded from the inside and outside during a calm morning with ambient air temperature of about 25º F and interior temperatures of about 70º F, and whole house air tightness was assessed with a blower door test. Whole house infiltration was ACH50=1.28 (very low). 11 Keller Court data (Table 14) was obtained with a multipoint blower door test. IR scans found no major infiltration pathways.

The ceiling and gable end of the vaulted living room were built with wood frame construction instead of precast concrete. Both showed higher heat loss than was generally found in the precast panels. Flaws in the continuity of ceiling insulation over the vaulted ceiling were visible from the vented attic, especially around can lights. The flat ceilings in this home were insulated with R-38 rigid polyisocyanurate loosely laid on the concrete ceiling panels. Dukane has now switched to an R-23 precast panel for ceilings.

Table 14. Dukane Precast’s Fortified Home Specifications

| Component | Dukane Home |

| Conditioned area | 5100 (with basement) |

| HERS ‘99 score | NA |

| Envelope | |

| Floors and Ceiling | Precast concrete panels |

| Walls | R-23 (~3") Polyisocyanurate between precast concrete |

| Attic | Vented with R-38 Polyisocyanurate and Batt |

| Windows | Insulated glass, vinyl frame, u-value=0.36, SHGC=0.45 |

| Infiltration | Ach50=1.28 |

| Equipment | |

| Heating | Radiant floor |

| Boiler | 140kBtu, 50 gallon AFUE=92 Gas Boiler |

| Cooling | 3 ton, 10 SEER, Unico-type |

| Ducts | High velocity, small ducts, unconditioned space |

| Thermostat | Programmable |

| Ventilation | Honeywell 150cfm HRV |

| Water Heating | From Boiler |

Opportunities for Improvement

|

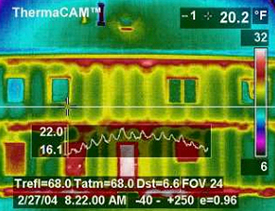

Figure 16. IR-scan

showing metal trusses in precast walls. Temperature at the crosshairs

is 20.2°F. Overlaid temperature graph shows temperature variation

of the surfaces at the white line running horizontally through

the crosshairs. |

Increased heat loss was also visible at the top and bottom of precast sections where field connections are made during construction and filled with grout. Each panel has at least two lifting fasteners imbedded in the top edge for the crane to connect to during home construction. Foam insulation around these fasteners is sometimes removed to connect the lifting hook and the void is re-insulated in the field. Insulation levels are reduced where precast walls are connected to floors and ceilings. These areas have one inch of rigid XPS foam (R-5) next to the outer panel but are otherwise left open until structural and electrical conduit connections are made in the field after which they are filled with grout.

Interior Ducts and Moisture Issues

FSEC Researchers met with Dukane Precast staff, their architect and mechanical

contractor to identify a way to incorporate interior ducts into a new

model of the Fortified House. Ducts are used primarily for

cooling and ventilation as all Dukane Precast homes are designed with

in-floor radiant heat driven by a high efficiency (92 AFUE) boiler.

The boiler also provides domestic hot water in conjunction with a 50-gallon

storage tank.

The main obstacle to building interior ducts was finding a place to run ducts from the basement mechanical room to the first and second floors. Agreement was made to run supply risers near the center of the home and returns in a chase on an outside. The two-story foyer offers the best placement for a central return for both the first and second floor supplies.

Dukane is currently using a high velocity, small duct air conditioning system by Unico with 2-inch diameter supply branches that are easier to fit into walls and chases than low velocity ducts. One unoccupied home had problems with condensation accumulating on the attic-mounted ducts. The cause was traced to humid indoor air contacting cold metal trunk lines in the vented attic.

No occupant-related moisture was present but the precast panels, which are still in the process of drying, are one possible source. Periodic mixing of the indoor air may be all that is required until moisture output from the panel is reduced. Otherwise, introducing dry air was recommended to prevent condensation. Findings and recommendations were sent of the Dukane Precast in a Trip Report.

Orlando, Florida Division

In December 2005, E. Martin met with the Orlando Division of DR Horton Homes to discuss resources available to them through the Building America and LEED for Homes program. DR Horton Staff from land development, purchasing, and home building divisions were present. They expressed interest in receiving assistance from BAIHP on multiple levels, and follow up conversations will take place in January.

Dye Company and DelAir -

Southern Living Home

Category A, 1 Home

Category B, 1 Home

Florida H.E.R.O. met with Dye Company president and his staff to discuss the new Southern Living Home planned for showcase at the 2003 Southeast Building Conference (SEBC) in Orlando, Florida. This firm has a strong desire to differentiate their homes by emphasizing healthy and energy efficient homes. Florida HERO introduced the Building America systems engineering approach to the builder and subsequent discussions resulted in Dye’s commitment to partner with Building America in this project. As a result, researcher met with DelAir mechanical contracting to discuss the development of mechanical specifications for the Southern Living project.

This home did have a Honeywell ERV added and had a HERS ‘99 score of 88.5. While this home did not meet the BA standard of performance for the 2003 SEBC show, retrofits were being completed to bring it up to BA performance level.

The 2004 home achieved a HERS ‘99 score of 89.6. Both homes have unvented attics with ducts in conditioned space, and used heat pumps with SEERs ranging from 13.5 - 14.1. Windows in the 2004 home had a SHGC of .29 and gas (LP) instant hot water heaters were used.

BAIHP Home | Overview | Case Studies | Current Data

Partners | Presentations | Publications | Researchers | Contact Us

Copyright © 2002 Florida Solar Energy Center. All Rights Reserved.

Please address questions and comments regarding this web page to BAIHP Master