II. BAIHP Technical Assistance - A

All

America Homes of Gainesville

Gainesville, Florida

Category A, 2 Homes

Awards: 2003

Energy Value Housing Award, Silver Medal, Custom Home/Hot Climate

2002

South East Builder's Conference, Grand Aurora Award for Solar Energy

|

Figure 4. All America Homes of Gainesville,

2003 Energy Value Housing Award, Silver Medal, Custom Home/Hot

Climate. |

All America Homes has been in business for 17 years and builds 10 homes each year in the Gainesville (FL) area. After providing design assistance for the award wining 2002 home (Figure 4) during the 4th budget period, BAIHP provided additional assistance to All America for a second home with solar and energy efficiency concepts during the 5th budget period. The home was built with a photovoltaic (PV) system, and achieved a HERS ‘99 rating of 90.6. This home serves as a model for the hot-humid climate using a combination of on-site power generation and energy efficiency to reach near-zero utility demand, similar to the home built in 2002 (Table 3).

It incorporates energy efficient air conditioning, hydronic solar water heating, excellent air distribution design and construction (pressure tested for validation) and right sizing of the heating and cooling capacity. It also incorporates envelope improvements in the roof, ceiling, walls, windows and infiltration control. A passive fresh sir ventilation system provides filtered outside air to the return side of the mechanical system during operation.

Table 3. All America Homes of Gainesville (FL) Specifications

Component |

2002 Home |

2003 Home |

| Conditioned Area | 3644 sq ft | 2884 sq ft |

| HERS ‘99 Score | 90.6 | 90.6 |

| Utility Cost | $150 for summer (including water, sewer, and trash pickup) (Source: Homeowner records.) | Average summer energy use = 58kw/day (Source: Gainesville Regional Util.) |

| Solar: PV Array | 2.5 kW | 1.8 kW |

| Solar: Water Heating | Integrated storage solar collector (4' x 8' ) EF.2.4 | Integrated storage solar collector (4' x 8' ) EF .4.7 |

| Solar: Water Heating | Solar pool heater | N/A - no pool |

| Solar: Attic Ventilation | PV powered attic fan | N/A – Unvented attic |

| Solar: Outdoor Lighting | PV (low-voltage) patio lighting. | N/A – No pool. |

| Heating | Hydronic coil with solar heated water and gas backup | Hydronic coil with solar heated water and instantaneous gas backup |

| Cooling | SEER 14 AC Variable speed AHU fan Maintains indoor RH =< 60% |

Dual compressor SEER 17 Variable speed AHU fan Maintains indoor RH =< 60% |

| Ducts | Interior Duct System Fur down construction |

Interior Duct System in Unvented Attic |

| Duct Leakage | CFM25out < 5% of AHU flow | CFM25out <5% of AHU flow |

| Roof/Ceiling Assembly | Radiant barrier roof decking R-30 dense pack cellulose (ceiling) |

R-20 Icynene at roof decking unvented attic |

| Wall Assembly | R-13 Dense pack cellulose | R-15 Blown in batt fiberglass |

| Windows | Reduced window area | |

| Glazing & Frame | Double pane, vinyl frame | Same |

| Window Radiant Gain | Large overhangs (high windows located beneath the roof overhangs to provide daylighting without contributing to solar heat gain) | Low-E glazing for unshaded east and west windows |

| Lighting | 85% fluorescent. | 95% fluorescent |

| Infiltration | Natural ACH < 0.1 | Est. natural ach =0.059 |

| Ventilation | Filtered passive fresh air inlet on the return side of AHU | Same |

AMJ Construction

Gainesville, Florida

Category A, 54 Town homes (ongoing)

Florida Home Energy Rating Organization (Florida H.E.R.O.) provided an engineered duct system for 26 models in the Regents Park Townhouse development. This downtown urban infill project will result in 54 units with Building America features including ductwork in the conditioned space, outside air ventilation, and combo hydronic heat and 13 SEER cooling. Each of the 54 units will be individually performance tested. Three completed units were tested, each scoring well over a HERS ‘99 score 89.

Applegren Construction, Eastern

Dakota Housing Alliance (EDHA)

Grand Forks, North Dakota

Category A, 10 Homes

Category B, 13 Homes

Awards: North

Dakota Housing Finance Agency’s Champion of Affordable Housing

Production Award

Papers: Cold

Climate Case Study: High Efficiency North Dakota Twin Homes

See Cold Climate Case Study: High Efficiency North Dakota Twin Homes

on www.baihp.org.

EDHA set a goal of achieving up to 50% energy savings over the 1993 Model Energy Code with superior indoor air quality (AIQ). Phase I (March 2003) and Phase II (Feb 2004) each included two twin homes (duplexes) for a total of eight homes.

|

Figure 5. Selkirk Twin Homes,

Grand Forks, ND. |

The two story dwellings (Figure 5) include an insulated basement with air circulation to the main house, suitable for conversion to living space. Features of the Phase I and Phase II homes are summarized in Table 4 which also shows a theoretical base case house using local conventional construction and code minimums modeled in DOE2 to determine energy savings and cost effectiveness. Estimated combined gas and electric utility savings ranged from 25% on Phase I homes to 35% on Phase II homes over the base case. The homes also met the BA goal of 40% savings compared to the Benchmark house.

A performance comparison of the base case and improved structures is shown in Table 5. The DOE2 model predicts the need for very little cooling, however many new homes in this area, including these, are being built with central air conditioning.

Moisture Issues

Phase II of construction added a layer of R-10 rigid extruded polystyrene (XPS) to the exterior side of the wall assembly. The low water vapor permeance of rigid XPS foam sheathing (1.1 perms) presents a dilemma in this climate where an interior vapor barrier (usually 6-mil polyethylene) is considered mandatory to minimize moisture diffusion from the conditioned space into the wall cavity. The installation of two vapor barriers leaves the wall vulnerable to moisture accumulation should water unintentionally enters the cavity. One BAIHP recommendation calls for removing the interior vapor barrier and relying on two coats of latex paint on the interior to limit diffusion from the conditioned space into the wall. This option allows the wall to dry to some extent in both directions, but was not chosen by the builder.

A heat recovery ventilator (HRV) mounted in the basement provides controlled mechanical ventilation with an energy penalty estimated at $45/year. The unit contains an 80-watt fan that introduces 75 CFM of outside air while exhausting a similar amount at a heat transfer efficiency of 70%. The HRV can operate either continuously or on an intermittent 20 minutes on, 40 minutes off cycle. Intermittent operation was simulated to meet the old guideline. Attempting to meet the new ASHRAE 62.2 standard (ASHRAE 1999) would require 42 CFM of continuous ventilation. For these simulations however, the old ASHRAE guideline of 0.35ACH was used, calling for a continuous rate of 25 CFM.

Table 4. Applegren Twin Home Specifications

| Component | Base Case | Phase I (March 2003) | Phase II (Feb 2004) |

| Conditioned Area Of Each Dwelling | 1840 sq. ft. (w/basement) | Same | Same |

| Hers Score | 85.2 | 89.7 | 92.2 |

| Estimated Annual Energy Cost | $1179 | $815 | $701 |

| % Cost Savings Compared to Base | 25% | 35% | |

| Heating Cost | $458 | $366 | $294 |

| Cooling Cost | $15 | $11 | $10 |

| Hot Water Cost | $245 | $157 | $116 |

| H/C/WH Total Cost | $718 | $534 | $420 |

| Envelope | |||

| Above-Grade Wall Structure | 2x6 wood frame | Same | 2x4 wood frame |

| Above-Grade Wall Insulation | R-19 fiberglass batt | Same | R-15 blown fiberglass |

| Above-Grade Wall Sheathing | Plywood | Same | R10 XPS foam corners: R7.5+plywood |

| Basement Walls | R-11 | Same | Same |

| Vented Attic | R-49 | Same | Same |

| Windows | Double pane, Low-E, Argon-filled, vinyl slider frame U=0.34, SHGC=0.33 |

Casement (instead of slider) |

Same as Phase I |

| Infiltration (ACH50) (Including Basement) | 5 (assumed) | 2.8 (average of 4 units) | 2.4 (average of 4 units) |

| Equipment | |||

| Gas Furnace | 60kBtu, AFUE=78 | 60kbtu, AFUE=92 w/sealed combustion | 60kBtu, AFUE=92 |

| Gas Furnace Capacity | 29.8kBtu/h | 33.4kBtu/h | 30.7kBtu/h |

| Air Conditioner | 1.5 ton, 10 SEER | Same | Same |

| Air Conditioner Capacity | 9.9kBtu/h | 10.6kBtu/h | 10.3kBtu/h |

| Thermostat | Standard | Programmable | Same as Phase I |

| Ventilation | None | 70% efficient HRV | Same as Phase I |

| Water Heater | 40 gallon, EF=0.88 Electric | 40 gallon, EF=0.62 Natural gas with power vent | Tankless, EF=0.83 Natural gas |

| Lighting | 10% fluorescent | 85% fluorescent (linear and CFL) Note: only bathroom and dimmable fixtures were incandescent |

Same as phase I |

| Appliances | Standard | Energy Star dishwasher Horizontal-axis washer Energy Star refrigerator |

Same as Phase I |

Cost Analysis

Tables 5 (Phase I) and 6 (Phase 2) show the cumulative effect of All Measures in comparison to the base case home. The heat recovery ventilator (HRV) is also shown separate from the other measures because the HRV is an essential IAQ feature, yet it increases energy use by $45/year. With the exception of the HRV all measures show a positive cash flow on a 6%, 30 year fixed rate mortgage beginning in the first year.

Table 5. Economic Assessment of Phase I Measures*,**

| Energy Measure | Annual Savings | Installed Cost | Simple Payback | First Year Cash Flow |

| Reduce infiltration to 2.8 ACH50 | $90 |

$325 |

3.6 |

$68 |

| Upgrade to 92% direct vent furnace | $52 |

$600 |

11.5 |

$11 |

| Switch to Programmable Thermostat | $23 |

$130 |

5.7 |

$11 |

| Upgrade to Energy Star appliances* | $61 |

$730 |

12 |

$12 |

| Change to EF=0.62 power vented water heater | $52 |

$520 |

10 |

$16 |

| Increase from 10% to 85% fluorescent lighting | $31 |

$200 |

6.5 |

$17 |

| All Measures | $309 |

$2,505 |

8.1 |

$135 |

| Heat recovery ventilation @75cfm, 33% RTF | ($45) |

$1,400 |

N/A |

($134) |

| All Measures with HRV | $264 |

$3,905 |

14.8 |

$1 |

| * Energy Star appliances include refrigerator, dishwasher and h-axis clothes washer. | ||||

| ** First year cash flow based on 30 year fixed rate mortgage with interest rate of 6%, down payment of 5%, and discount rate of 5%. A general inflation rate of 3% per year was applied to the upgrade cost of measures replaced at end of lifetime. Final value of equipment is determined by linear depreciation over lifetime. Interest paid on mortgage is considered tax deductible using a tax rate of 28%. Energy costs escalate at 3% per year. A property tax rate of 0.8% was applied to the energy upgrade cost and is inflated at 3% per year. | ||||

The higher savings of Phase II over Phase I arise from two energy saving measures unusual for this region: XPS foam sheathing with 2x4 framing and tankless gas water heating. Simple paybacks for these measures were 8.3 and 13.3 years respectively. Electric water heaters are the current norm in the Grand Forks area, but with electricity 26% below the national average and natural gas prices on the rise, simple payback on the tankless model was relatively long. In addition, fluctuating natural gas prices complicate the economic analysis. Initial concerns of how the tankless water heater would perform in this extreme climate were met with positive feedback through the first winter, which was colder than normal including an all-time record low of -44ºF set at the Grand Forks International Airport on January 30, 2004.

Table 6. Economic Assessment of Phase II

| Energy Measure | Annual Savings |

Installed Cost |

Simple Payback |

First Year Cash

Flow |

| Upgrade walls to (R10 sheath + R15 FG batt) | $72 |

$600 |

8.3 |

$31 |

| Reduce infiltration to 2.4 ACH50 | $106 |

$325 |

3.1 |

$82 |

| Upgrade to 92% direct vent furnace | $40 |

$600 |

15.0 |

-$1 |

| Switch to Programmable Thermostat | $18 |

$130 |

7.2 |

$6 |

| Upgrade to Energy Star appliances* | $60 |

$730 |

12.2 |

$12 |

| Change to EF=0.83 tankless gas water heater | $94 |

$1,250 |

13.3 |

$10 |

| Increase from 10% to 85% fluorescent lighting | $31 |

$200 |

6.5 |

$18 |

| All Measures | $421 |

$3,835 |

9.1 |

$158 |

| Heat recovery ventilation @75cfm, 33% RTF | ($43) |

$1,400 |

N/A |

($134) |

| All Measures with HRV | $378 |

$5,235 |

13.8 |

$24 |

Phases III and IV Selkirk Homes

Table 7. Completed Selkirk Homes

Phase I |

Phase II |

Phase III |

Phase IV |

|

| Number of Homes | 4 |

4 |

4 |

4 |

| Completion Date | Mar-03 |

Jan-04 |

Aug-04 |

Jun-05 |

| HERS ‘99 score range | 88 – 90 |

92.5 |

88 – 89.5 |

91 |

| BA Benchmark range | 25 – 30% |

40% |

TBD |

TBD |

In 2005 and 2006, BAIHP provided technical assistance this partner for Phases III, IV, and V (Table 7, Completed Selkirk Homes). Lower HERS ‘99 scores (88.3 – 89.5) on the Phase III units was primarily due to electric resistance water heating (instead of tankless gas) and higher overall duct and envelope leakage. All of the 16 dwellings have outside air brought to the air handler return plenum with 14 of 16 units utilizing heat recovery ventilators (HRVs). Other specifications are outlined in Table 8.

Table 8. Selkirk Split-level Twin Home Specifications – Phase IV

| Conditioned Area | 1864 sq.ft. (including basement) |

| Above-grade Walls | Wood Frame (R15+R10 sheath) |

| Sub-grade Basement Walls | R22 Insulated Concrete Forms |

| Ventilated Attic | R-49 |

| IG Vinyl Windows | U-0.34, SHGC-0.33 |

| Heating System | Sealed Combustion Gas Furnace 60kBtu, AFUE-93 |

| Ducts/Return air | Central return / hi-lo bdrm return |

| Air Conditioning | Straight AC 1.5-ton, 10 SEER |

| Water Heater | Tankless Gas EF 0.83 |

| Thermostat | Programmable |

| Lighting | 85% Fluorescent |

| Ventilation | 70% HRV |

Phase IV floor plans were nearly identical to that used in Phase III featuring a split level design and attached garage instead of the below grade basements and detached garages used in Phases I and II. (Figure 6)

|

Figure 6. Two

completed Phase

IV units (Dec 2005) at Selkirk |

Significant improvements in duct leakage to the outside were seen in Phase IV over Phase III. The improvements resulted from moving the air handler from an enclosed closet in the garage to the basement and using a central return instead of distributed returns which were found to be very leaky with QnOUT measurements of 0.05-0.09 compared to the improved QnOUT measurements in Phase IV of 0.01 to 0.03.

As with previously tested homes, total leakage was still very high and concentrated mostly on the return side where duct pathways were partially constructed by enclosing building cavities. Pressure measurements revealed that with interior doors closed, bedrooms pressures were around +1.0 Pascal, well within the acceptable range. Only the larger bedroom was fitted with a high/low return area pathway.

Each Phase IV unit was tested individually for envelope tightness. Leakage was noticeably higher with an average ACH50 of 4.3, versus the 3.5 seen in the similar Phase III design. No attempt was made to determine leakage through the shared wall of the adjoining unit but this should be similar to the test results on Phase II which found 50CFM of inter-unit leakage.

Table 9. HERS ‘99 Scores and Test Results for Selkirk Phase IV

| Rating | Envelope | Ducts | ||||||

Unit |

HERS ‘99 |

CFM50 |

ACH50 |

ACH |

C |

n |

R |

CFM25out |

1034 |

91.2 |

973 |

3.89 |

0.26 |

72.7 |

0.66 |

0.99 |

30 |

1042 |

90.7 |

1096 |

4.4 |

0.20 |

48 |

0.80 |

0.99 |

58 |

1050 |

91.3 |

1153 |

4.6 |

0.35 |

106 |

0.61 |

0.99 |

26 |

1058 |

90.3 |

1070 |

4.3 |

0.35 |

114 |

0.57 |

0.99 |

62 |

| Notes: - ACH50 calculation includes area of conditioned basement | ||||||||

Improved HERS ‘99 scores in Phase IV can be attributed to reduced duct leakage and switching from electric resistance water heating back to tankless gas units.

Phase V Selkirk Homes

The final phase of Selkirk will consist of six single-level, duplex homes with basement and attached garage, bringing the total build-out to 22 units. Based on past construction practices and equipment efficiencies, this home design should attain a HERS ‘99 score of at least 90 assuming an electric resistance water heater and 92.5 with a tankless gas water heater. Discussions for improving efficiency on these final units even further have centered on the use of a combined space and water heating boiler which may boost the HERS ‘99 score beyond 93. Favorable solar orientation for these homes may allow the use of high solar gain windows to further reduce heating loads.

Other ideas discussed:

-

Combining space heating and hot water with a high efficiency central gas boiler.

-

A central boiler design would require an air handler with a hydronic heating coil which could also incorporate an air conditioning coil.

-

An air handler with integrated HRV is available from at least one manufacturer (Lifebreath) which could reduce first cost by eliminating a separate HRV.

-

The air conditioning load for Phase 5 appears even lower than in previous designs and may justify a heating-only system. In that case, additional savings could be achieved with base-board hydronic heat.

Atlantic Design and Construction

Gainesville, Florida

Category A and B, 340 Homes (built out in 2006)

Awards: 2001 EPA Energy Star Small Builder of the Year

Papers: Fonorow,

Ken, Subrato Chandra, Eric Martin and Janet McIlvaine, 2006. Energy

and Resource Efficient Communities through Systems Engineering: Building

America Case Studies in Gainesville, FL. Proceedings of the 2006 ACEEE

Summer Study, American Council for an Energy Efficient Economy, Washington,

DC, August 2006.

Atlantic Design (AD) and Construction’s Mentone Subdivision in Gainesville, FL: 340 homes built out fully in 2006. AD was the winner of the 2001 US Environmental Protection Agency’s (EPA) Energy Star Small Builder of the Year and has achieved their current level of performance through an incremental process of improvements over several years. AD is a small, privately held residential construction company located in Gainesville, FL. Founded in 1985, the firm now directly employs 15 full-time employees and sells about 50 - 60 homes a year. See Figure 7 for a typical home. Like any business, AD is interested in both short-term and long-term profitability.

Figure 7. Atlantic Design and Construction home in the Mentone neighborhood.

While having developed a reputation for building high “quality” homes, the only aspects of their homes which were greater than minimum code requirements was the use of double pane glass and R-30 attic insulation (see Table 10). New materials and systems have been adopted over time. Two factors lead the builder to implement quality control/energy cost changes. First, the builder genuinely had the desire to do the right thing and wanted to provide his clients with a quality home. If the quality of that product could be quantified – all the better. Second, AD had just shifted from a custom homebuilding company to a production company with this subdivision. Though they were already exceeding the minimum Florida Energy code required, they were still flexible enough in these early stages to consider practice changes if those changes could be streamlined/standardized to minimize disruption to the production schedule. Any changes to the production procedures or standard features, however, would need to be backed with proof of their efficacy.

Table 10. Atlantic Design and Construction Specifications

| Component | Original | Mentone |

| Conditioned Area | 1800-2400 sq. ft | 1800-2400 sq. ft |

| Hers Score | ~82 | ~89 |

| Selling Price | ~$90,000 | $190,000 - $325,000 |

| Cooling | SEER 10 with standard thermostat | System sized using Manual J (reduced 1 ton), SEER 13 with passive, filtered ventilation air and programmable thermostat |

| Ducts | Local conventional construction | System engineered using Manual D, mastic sealed, and performance tested to have cfm25out < 5% of AHU flow |

| Ceiling Insulation | R-30 fiberglass | R-30 cellulose |

| Wall Assembly | R-11 fiberglass | R-13 cellulose |

| Windows | Double pane clear metal frame | Double pane Low-E |

| Lighting | Standard | Air lock can lights |

At this point, AD was interested in determining what features would need to be added and procedural changes that would need to be made to market their product as Energy Star. To make that determination, Florida Home Energy and Resources Organization (FL H.E.RO.) performed a room-by-room Air Conditioning Contractors Association (ACCA) Manual J load calculation from building plans for a model/Parade home about to begin construction. Results found that right-sizing equipment and developing and implementing strict procedural insulation and mechanical system specifications allowed the mechanical system to be reduced by a full ton. Increasing the air conditioner seasonal energy efficiency ratio (SEER) from 10 to 12 resulted in the home meeting the minimum level required for Energy Star home certification (Home Energy Rating System score of 86 or greater). Savings derived from decreasing the cooling system capacity more than offset the additional $250 - $375 needed for improved duct sealing and insulation and air sealing protocol adjustments. This savings, while sufficient to offset the costs associated with improved sealing methods, was NOT enough to pay for all implemented measures. Increasing the price of the home by $1,250 - $2,500 was sufficient to cover all additional costs AND derive an excellent profit margin. In order to ensure consistent pricing and profit, part of the builder’s job was to bid the criteria for insulation and mechanical specifications among multiple subcontractors. FL H.E.R.O. followed up with the contractors during duct rough-in to educate workers on the specifications and ensure quality installation.

Energy Star®. The builder decided to include “Energy Star” on the homebuyer’s option checklist. If this option was selected, the builder agreed to upgrade the cooling system efficiency to SEER 12, install an electronic programmable thermostat, install sealed and verified ductwork and increase wall insulation to R-13. As one of a list of options, sales of the Energy Star option were not brisk initially. After an analysis of the options program, FL H.E.R.O pointed out to AD that the Energy Star option was the most profitable option on their list, based on the percentage mark-up. As a result, marketing of Energy Star became more aggressive and included sales force training on selling the program. Buyers who didn’t select Energy Star during the closing process were contacted directly by the Project Superintendent. His goal was to explain the value of including energy efficiency, the loss of revenue from not selecting it, and to allow buyers a second chance to include the option. A study commissioned by the EPA and conducted by the University of Florida (UF) verified the energy savings from implemented improvements. By comparing the actual electricity and gas usage from utility billing information, and comparing this to similarly sized and aged code minimum homes, UF determined that the energy efficient homes built by AD resulted in an average annual energy savings of 12.7 Mbtu (savings ranged from 8.4 Mbtu minimum to 17.5 Mbtu maximum). Using this study’s data to proportion approximately 50% of the energy use as electric, and approximately 50% of the energy use as gas, and applying current Gainesville Regional Utilities rates results in an average monthly savings of $23 and a maximum monthly energy cost savings of approximately $30. Finally, AD’s President negotiated a deal with the preferred lender’s mortgage broker that resulted in a 1/8th point discount of the prevailing rates for every home that was designated Energy Star. This allowed the sales representatives an opportunity to demonstrate how much it would COST the buyer NOT to select the Energy Star option! After more than 120 buyers in a row selected this option, it became a standard feature for the builder.

The value of an Energy Star home in the Gainesville, FL market can now also be communicated to buyers in terms of increased resale value. An appraisal obtained on an AD Energy Star home showed a $4,000 increase in appraised value over a similar home in the same area that did not contain the energy efficient features (http://www.natresnet.org/ratings/). Also, the local area Multiple Listing Service (MLS) service has become the first in the nation to include information regarding a home’s status with regard to Energy Star on all listings.

Building America. With Energy Star so ingrained in the AD production process, FL H.E.R.O. worked to ratchet-up the builder’s home parameters by introducing him to Building America (BA) concepts. Having been exposed already to a systems engineering approach, the builder was primed to consider additional ways they could enhance their homes and their marketability. BA opened new avenues for them to increase energy efficiency, durability and enhance indoor air quality. Shifting their minimum standard upward to include a 13-SEER air-conditioning system, 0.90+ annual fuel utilization efficiency (AFUE) heating system and low emissivity (low-E) spectrally selective glass, the builder also embraced positive home pressurization principles through the introduction of filtered outside air to the return side of the plenum. The new upgrades resulted in this production builder’s homes achieving an average Home Energy Rating System (HERS ‘99) score of 89.

Location. Location. Location. Blueprints called for garage air handler (AH) installations in AD’s standard home. In a hot and humid climate, this architectural design element alone can cause all sorts of problems for the homeowner. In moisture laden climates, ambient conditions in a garage can accelerate rusting in the ferrous heat exchanger and increase evaporator coil sweating, both of which reduce the life expectancy of the heating and cooling system. Any air leakage especially at the blower fan, the point of greatest pressure differential, can introduce the home to moisture, outdoor irritants, automobile exhaust and toxic fumes from the substances most people store in their garage. Insufficient insulation of the AH and leaks on the supply side also lead to moisture condensation on the equipment and its associated ductwork. On the return side of the system, ductwork holes bypass all filters and create a pathway for hot moist air and/or pollen laden outside air to enter the home.

An on-site demonstration with a simple smoke stick, made invisible airflows visible and clinched this builder’s interest. Armed with a clearer understanding of the ramifications of locating the AH in the garage, the builder was convinced of the value of an indoor installation. Initial design modifications forced the mechanical contractor to work in a closeted space that was simply not large enough to allow a good installation. The addition of a duct board plenum adjacent to the furnace from an extended return, made sealing the system almost impossible. Code also required the provision of high and low combustion air to a furnace located within the thermal envelope of a home. Supply of this combustion air put the closet into communication with the attic and resulted in the movement of attic air to the living space via leaks in the duct system.

After multiple approaches were tried, an acceptable method was developed using a .90+ AFUE sealed combustion gas furnace. The sealed system eliminated the need for combustion air from the attic and allowed the equipment room to be completely sealed from the garage and the attic. Supply and return plenums were stubbed-out in the mechanical closet during rough in, and duct, plenum and refrigerant lines were sealed to the sheetrock with an expandable foam at all seams and penetrations. During equipment set, the supply side plenum was first affixed, and then completely sealed with mastic and pressure sensitive tape. A metal tap installed in the return air plenum at ceiling height, was attached to an insulated flex duct, which was connected to a second tap on the furnace side. All duct connects are made with mastic and fiberglass mesh. An insulated exterior door for the mechanical closet with appropriate weather-stripping and threshold sealing completed the installation. Realizing that this approach would increase profits by increasing the home’s conditioned square footage and provide clients with a safer and more energy efficient home, AH location changes were made to all model blueprints.

Indoor air quality. Though indoor air quality was a subject not yet broached, demonstrating the principles of air movement into a tightly constructed home was an educational experience for the superintendent. It quickly became clear to him that controlling how and where outside air was introduced into the home could make a big difference in the indoor air quality (IAQ). In many new homes it is common to have some amount of supply duct leakage resulting in the home being negatively pressurized because the ductwork is commonly located outside the home’s air and thermal boundaries. In a negatively pressurized home, outside air is introduced in an uncontrolled fashion through inadvertent gaps around windows, doors or top and bottom wall plates. Installing a simple, low cost, non-mechanical fresh air system helps restrict the uncontrolled entry of hot, humid, pollen-laden air into a home and its interstitial areas. Filtering the outside air and directing it through the home’s air conditioning system prior to entry ensures mitigation of the outside air’s hot, humid, and pollen-laden characteristics. Including this fresh air system not only made AD’s home more efficient, but more importantly it improved IAQ. This fresh air system now is a standard feature in all of the homes they build.

Avis

American Homes

Avis, Pennsylvania

Papers: Mullens,

M., & Burdick, J. (2003). “Energy Test Results and Recommendations

for Avis America Homes.” University

of Central Florida Housing Constructability Lab BAIHP Report, Cocoa,

FL.

Broadway, R. and M. Mullens (2004). “Shop Floor Information Systems for Industrialized Housing Production,” Industrial Engineering Research ’04 Conference Proceedings, Houston, May, 2004.

|

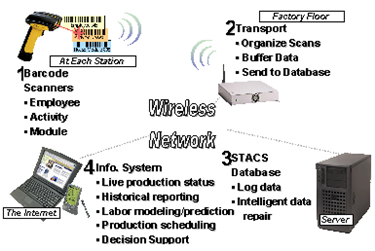

Figure 8. STACS system components

and relationships. |

In the summer of 2003, Avis American Homes tested an alpha prototype Status and Control System (STACS) developed by the UCF Constructability Lab researchers (BAIHP Partner). The system is a real-time shop floor labor data collection and reporting system. Production workers use wireless laser scanners to report their current work assignment. STACS reporting is web based and provides both real time manufacturing status and summaries of historical production performance (Figure 8). While labor represents a relatively modest fraction of production cost, typically 10-15%, it has a profound impact on operations, including product quality, cycle time, material waste, and labor productivity.

Avis American employees tested STACS in drywall finishing operations. Test results demonstrated that production workers could operate the system effectively and that the system accurately captured scanned activity.

See also Penn Lyon Homes (Technical Assistance section) and Status and Control System (STACS) (Research Section III).

BAIHP Home | Overview | Case Studies | Current Data

Partners | Presentations | Publications | Researchers | Contact Us

Copyright © 2002 Florida Solar Energy Center. All Rights Reserved.

Please address questions and comments regarding this web page to BAIHP Master