|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Disclaimer: This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat

and Non-Heat Recovery Ventilation Performance in Energy-Efficient

HUD-Code Manufactured Housing |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Michael

Lubliner, Andrew Gordon, Adam Hadley, and Danny Parker Washington State University Energy Program, Olympia, WA 98502, USA Bonneville Power Administration, Portland, OR 97208, USA Florida Solar Energy Center, Cocoa, FL 32826, USA |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Abstract The Zero Energy Manufactured Home Project demonstrates and promotes innovative energy saving technologies to the manufactured housing industry and home buying public, while evaluating those technologies’ energy performance. The project, funded by the Bonneville Power Administration, and the U.S. Department of Energy’s (DOE) Building America Industrialized Housing Program (BAIHP), examines two 147 square meter (m 2) (1600 ft 2) two-section manufactured homes, built by the same manufacturer, using an identical floor plan. Heating ventilation and air-conditioning (HVAC) measurements, envelope and duct leakage tests were conducted and remote monitoring equipment installed to track the performance of each home over a three year period. Both homes were built in the summer of 2002 and sited in the cold, dry climate of Lewiston, ID. The Zero Energy Manufactured Home (ZEMH) has been built with highly efficient and cutting edge technologies including a photovoltaic system, sun-tempering, solar water heating, spray-in foam insulation, heat recovery ventilation, and Energy Star appliances, HVAC and lighting The comparison (ESTAR) home is built to Energy Star Program requirements as part of the Northwest Energy Efficient Manufactured Home program, which includes a quiet 20 watt whole house exhaust fan ventilation system. Energy Star is the most energy efficient home that meets the U.S. Department of Housing and Urban Development code available in the United States market today (NEEM). This paper presents the field testing and monitoring results of both homes’ heat recovery (HRV) and non-heat recovery (NHRV) ventilation system energy performance, based on in-situ monitoring data. Energy Gauge USA computer simulation software is used to compare the ventilation, envelope and duct leakage induced infiltration in the ZEMH and ESTAR homes. Anecdotal and occupant related observations are presented, along with some conclusions. Keywords Heat recovery ventilation, indoor air quality, energy efficiency Poster View the one-page poster of this paper. Poster (pdf - 417kb) Introduction More than 200,000 factory homes are built in the United States each year to the federal manufactured housing standards (HUD 1994). Issues related to energy efficiency, heating, ventilation and air-conditioning standards and performance in these homes has been presented in previous AIVC papers (Lubliner 2000, 2003 ), (Persily 2003). HUD code manufactured homes tend to be built tighter than site built homes, which is why codes require whole house mechanical ventilation systems. (HUD 1994), (TenWolde 1996), (Stevens 1997). HUD requires ventilation systems capable of ventilating the ZEMH and ESTAR homes be at least 26 liters per second (l/s) (56 ft 3/min). For these homes the sizing approach in the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 62 (ASHRAE 2003) would require a comparable 29 l/s (61 ft 3/min). The ZEMH was built with energy efficiency and renewable energy as a high priority, in an effort to evaluate proposed future energy efficiency targets. The BAIHP targets seek to demonstrate future whole house energy savings of 60-70 percent over current practice, while improving indoor air quality and durability. (Lubliner 1994) Energy modeling of the ZEMH suggests that it achieves the 60 percent target. The ESTAR home achieved the current BAIHP 30 percent target. Analysis that compares modeled and actual total and end-load technology energy use in ZEMH and ESTAR home is currently under way. HVAC System Descriptions: Heat Pump: Both the ZEMH and ESTAR homes are all-electric homes with HVAC systems located in the utility room. They both have 7 kilowatt (kW) (2 ton) ducted unitary air-to-air heat pumps with electric resistance backup. All heat pump components, including the outdoor coil, are located inside a small closet in the house. The heat pump draws air from the crawlspace, directs it across the outdoor coil, and exhausts it through the ceiling and roof cap. Investigations are currently under way to determine the heating and cooling performance of the heat pump compared with typical split system heat pumps and electric furnaces. Ductwork: The heat pump duct system has a single return air grill located in the utility room. Supply ducts distribute conditioned air to floor registers in the other rooms via riser and trunk ductwork located above the floor insulation. A crossover duct in the vented crawlspace connects the trunk ducts of the two home sections. The use of duct mastic and air-tight Icynene ™ foam floor insulation in the ZEMH ensures that the supply riser and trunk ducts are airtight and well within the indoor pressure and insulation boundary with minimal heat transfer between the house and the crawlspace. The ESTAR home has a leakier duct system as a result of the use of foil duct tape and because the ducts are located in a loose-fill insulation. Since 2003 all Energy Star homes in the Pacific Northwest are required to use mastic instead of tape to seal ductwork. The forced air distribution system introduces inefficiencies caused by conduction heat transfer between the ducts and the crawlspace, duct leakage to the crawlspace, and duct leakage induced infiltration. Duct leakage induced infiltration results when supply air duct leakage causes negative pressures within the home relative to the outdoors. Supply duct leakage has been shown to be a significant contributor to uncontrolled air infiltration that increases with the HVAC operational time. (Palmiter 1992) (Persily 2000, 2003). During the winter heating season, longer HVAC operation time combined with greater stack infiltration result in high air change rates. In homes with leaky ducts and envelopes this can result in significant over ventilation and reduces the need for the continuous mechanical ventilation system to operate. The ZEMH’s tighter ducts and building envelope reduce winter periods of over ventilation making the HRV an important component to the philosophy “build tight; ventilate right.” Table 1: Duct & Envelope leakage and Ventilation System Flow Rates

Table 1 provides a comparison of supply duct and envelope leakage in ZEMH and ESTAR homes using Duct Blasters™ and Blower Doors™ typically employed to test energy efficient homes. Both the ductwork and envelope are considerably tighter in the ZEMH. The difference in both total duct leakage and duct leakage to outside in the ZEMH show the ducts are tighter and that more air leaked through the ducts goes back into the house instead of the crawlspace. HRV

Operation: HRVs are typically used in cold climates to

efficiently supply a steady flow of fresh outdoor air. As stale

warm air is expelled, the heat recovery core warms the incoming

fresh, colder air before it is distributed throughout the home.

The result is a constant supply of fresh air, no unpleasant

drafts, and greater home comfort. In addition to heat recovery

and improved air quality, the HRV provides necessary ventilation

while controlling excess humidity. The HRV in the ZEMH is a

Venmar 3000™, which is designed to save energy while

ventilating and providing High Efficiency Particulate Air Filters

(HEPA) filtration of outside and re-circulated air. The Venmar

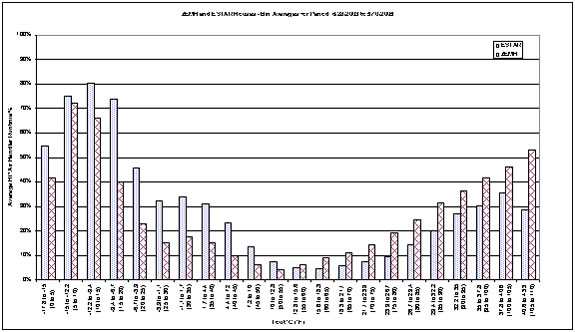

3000 has a replaceable HEPA filter and separate pre-filter. Defrost Mode: To ensure that the HRV does not freeze the HEPA 3000 employs a defrost mode with variable timing depending on the outside temperature. When the outside air temperature is between -5º C and -15ºC (23ºF and 5ºF), a mechanical damper shuts the outside air entering the HRV for six minutes every 30 minutes as the defrost mode. This allows the re-circulation air to warm the core. When the outside temperature is between -15ºC and -27ºC (5ºF and -17ºF), the HRV runs in defrost mode for nine minutes every 30 minutes, and 20 minutes every 30 minutes when the outside temperature is below -27º C (-17ºF). (Forest) During 2003-2004, the HEPA 3000 was in defrost mode for about 9 hours. HRV Distribution Effectiveness: The HRV duct design in the ZEMH is independent of the heat pump ducts and not directly ducted to bedrooms. Connecting the HRV to the heat pump ducts would require the 350 watt heat pump blower fan to operate continuously, causing electricity use of up to 3300 kilowatt-hours (kWh) per year. The ZEMH independent duct design reduces energy use. However, it also reduces spatial mechanical ventilation effectiveness in bedrooms when the heat pump is not operating. Research has shown that spatial ventilation effectiveness is improved as the central forced air heating/cooling system operates more frequently to mix the fresh air from the HRV with the indoor air. (Persily 2000) Figure

2. Run time of the ZEMH and ESTAR homes vs. Outside Temperature Figure 2 shows the percentage runtime as a function of outdoor temperature for both the ZEMH and ESTAR home. As expected the runtime increases as the outdoor temperature gets lower during the heating season and increases as the outdoor temperature get higher during the air-conditioning season. The lower runtime in the ZEMH during heating is because the home is more energy efficient and both homes use identical heat pumps. The higher runtime in the ZEMH during the cooling season is a result of the occupant using the heat pump in air-conditioning mode more often in part due to dust, simplicity, and daytime occupancy. The ESTAR occupant relies more on opening windows at night to provide diurnal cooling, instead of using the heat pump. Both occupants will typically open windows when the outside temperature falls within this temperature range. When the heat pump system runs at night, occupants benefit from greater air distribution to the bedrooms. A Venmar duct accessory product currently under development will integrate both duct systems and allow for HRV fresh air to be supplied to all ducted rooms without requiring the operation of the higher wattage heating/cooling fan. This product will improve spatial ventilation effectiveness, will have no negative impact on heating and cooling systems if it uses the same ductwork, and will reduce fan energy use by not relying on the operation of the air handler blower. Another innovative ventilation control used to improve ventilation effectiveness in many energy efficient site built homes is the Fan Recycler™, which ensures that ventilation and indoor air are mixed by the existing forced air system a minimum set time period every hour, by monitoring the HVAC fan runtime. (Rudd) HRV Maintenance and Operation: The HEPA filter is recommended to be replaced every year. The pre-filter of the HEPA cartridge, HRV core filters and inside of the HRV should be cleaned every six months. The difference in flow rates between the clean and dirty pre-filter was found to be less than 10%, with the HVR core 6-months old. The occupants were asked to run the HRV continuously and use the boost mode when they desired additional ventilation. The HRV in the ZEMH was operated primarily in normal mode. The boost mode was rarely used. The re-circulation mode eliminates outside air. This mode is intended for use during periods when outdoor pollutants are present. Instead of using the re-circulation mode, the occupants shut the HRV off because of problems with dust, insects and barbeque smoke, which they associated with the HRV. These issues resulted in the HRV being turned off for extended periods of time during the summer of 2003. Discussions with occupants and resolution of problems resulted in HRV continuous operation in 2004-05. HRV Efficiency: The tested HRV net efficiency is 56% provided by Venmar for the HEPA 3000. The net efficiency varies with outside air temperature and flow rate. While there is no industry approved method or test to evaluate the energy recovery efficiency of multifunction products such as the Venmar HEPA 3000, laboratory testing was conducted using CSA C439-00 C439-00 (Standard Laboratory Methods of Test for Rating the Performance of Heat/Energy-Recovery Ventilators) with some adaptations to take into account the impact of blending indoor air inside the unit. The net efficiency has been evaluated from the gross temperature recovery efficiency (defined as apparent effectiveness in CSA C439) to which several penalties were subtracted: unbalance factor, exhaust air transfer, casing air leakage, casing heat gain/losses, defrost energy (when applicable) and fan energy. (Forest) The measured power consumption of the HRV blower motor in the ZEMH was 164 watts and 228 watts on normal mode and boost mode, respectively. The manufacturer reports that 85 percent of the heat generated from the motor is transferred to the incoming air downstream of the heat exchanger core with the remaining 15 percent transferred to the exhaust air downstream of the core. The high wattage of the Venmar 3000 blower is a result of the HEPA filtration option. Other small wattage Venmar HRV models such as the Duo 1.2™ do not employ HEPA filters and uses only 68 watts to provide 32 l/s (68 ft 3/min) at an 87 percent apparent sensible effectiveness at 0º C, (32º F). NHRV: The ESTAR home utilized a Panasonic #FV-08Q2 Whisper Ceiling™ whole house exhaust fan. The fan is located in the utility room to provide non-heat recovery ventilation. The fan is designed and controlled to operate continuously. A circuit breaker must be turned off to disable operation. The exhaust flow rate was measured at 37 l/s (78 ft 3/min) using a flow grid that measures average velocity. Unlike the HRV, the NHRV fan causes a slight depressurization of the home relative to the outdoors. This depressurization causes outside air to enter the home via air leakage pathways in the thermal envelope and ductwork. The location of these leakage pathways dictates the spatial ventilation effectiveness associated with the NHRV system when the heat pump is not operating. Depressurization from the supply duct leakage and NHRV increases ventilation rates. The NHRV exhaust fan flow rate is added in quadrature to the stack effect because of changes in the vertical neutral pressure location. This results in higher flow rate capacity fan required to provide equal mechanical ventilation as the balanced HRV system. For the balanced HRV, the flow rate and stack effect are simply additive. Energy Gauge USA Simulation: Energy Gauge USA version 2.4 was used to estimate the space heating, cooling and ventilation fan energy for the ZEMH and ESTAR homes as shown in Table 2a. Table 2b compares energy use for a variety of real and theoretical cases. All ventilation cases assume 33 l/s (70 ft 3/min). The difference between runs No.1 to No.2 in ZEMH and No.5 to No.6 in ESTAR show the energy savings associated with not using the HEPA option when using an HRV. The difference between runs No.2 to No.3 in the ZEMH and No.6 to No.7 in ESTAR show the energy savings associated with the HRV over the NHRV. The difference between the Non-ventilation Case 8 over the other ventilation cases highlights the cost of ventilation to achieve improved IAQ. The ventilation system case comparisons in Table 2b indicate greater savings for the ESTAR home than the ZEMH. This is believed to be a result of ZEMH having both lower house and heat pump balance points. Table 2A: Energy Gauge Simulation Energy Use Results

Table 2B: Case Comparisons

Costs: The HEPA 3000 costs $1,100 U.S., Duo 2 costs $700 U.S. and the NHRV costs $150 U.S. These are costs of the equipment and do not reflect installation, and markups. The HEPA 3000 has a $100 U.S. annual maintenance cost to replace the HEPA filter. The other units have no annual maintenance costs; cleaning maintenance is assumed to be provided by the occupants at no cost. The useful life of these systems is unknown. It should also be noted that the HEPA filtration non-energy benefits to indoor air quality need to be considered when looking at first and operating costs. These benefits may include the avoidance of health care expenses—such as the cost of a respiratory inhaler and doctor visits—which can far outweigh the cost of energy recovery. Conclusions

Acknowledgments This work is sponsored in large part by the U.S. Department of Energy Office of Building Technology’s Building America Industrialized Housing program under Cooperative Agreement DE-FC36-99GO10478. Special thanks to Daniel Forest, Venmar Ventilation Inc. Additional support has been provided by: The Bonneville Power Administration, the Florida Solar Energy Center, the Washington State University Extension Energy Program, the Nez Perce Tribe, Kit Manufacturing, Clearwater Homes and the Northwest Energy Efficient Manufactured Home Program. References American Society of Heating, Refrigerating and Air-Conditioning Engineers (1988) ASHRAE Standard 119-1988, Air Leakage Performance for Detached Single-Family Residential Buildings. American Society of Heating, Refrigerating and Air-Conditioning Engineers (2003) ANSI/ASHRAE Standard 62.2, Ventilation for acceptable indoor air quality. Canadian Standards Association (2000) CSA C439-00. Standard Laboratory Method Test for Rating the Performance of Heat/Energy Recovery Ventilators. ECOTOPE 2003 Summary of SGC Manufactured Home Field Data 1997-98: Sitings in Idaho and Washington. Ectope, Inc., Seattle, WA. Forest, D. Conversations with Danial Forest, Venmar AVS, 2005. U.S. Department of Housing and Urban Development (1994) Manufactured Home Construction and Safety Standards, Part 3280. Washington, D.C. Lubliner, M.; Stevens, D.T.; and Davis, B. (1997) Mechanical ventilation in HUD-code manufactured housing in the Pacific Northwest. ASHRAE Transactions, 103 (1), pp. 693-705. Lubliner, M. et al (2003) Building Envelope, Duct Leakage and HVAC System Performance in HUD-code Manufactured Homes. 24 th AIVC Conference Proceedings. Brussels, Belgium. Lubliner, M. et al (1997) Mechanical ventilation in HUD-code manufactured housing in the Pacific Northwest. ASHRAE Transactions, 103 (1), pp. 693-705. Lubliner, M.; Gordon, A. (2000) Ventilation in U.S. Manufactured Homes: Requirements, Issues and Recommendations. 21 st AIVC Conference Proceedings. Lubliner, M, et al (2004) Manufactured Home Performance Case Study: A Preliminary Comparison of ZeroEnergy and Energy Star. Performance of Exterior Envelopes of the Whole Building IX International Conference, American Society of Heating, Refrigerating and Air-Conditioning Engineers. NEEM (2004) Northwest Energy Efficient Manufactured Home Program In-Plant Inspection Manual, Oregon Office of Energy. Palmiter, et al (1992) Measured Infiltration and Ventilation in Manufactured Homes. Ecotope, Inc. Persily, A.K. (2000) A Modeling Study of Ventilation in Manufactured Homes. National Institute of Standards and Technology, Gaithersburg. Persily, A.K., et al (2003) Ventilation Characterization of a New Manufactured Home. 24 th AIVC Conference Proceedings. Air Infiltration and Ventilation Centre, Brussels, Belgium. Rudd, Armin F.; Lstiburek , Joseph W. (2000) Measurement of Ventilation and Interzonal Distribution in Single-Family Homes. ASHRAE Transactions 2000, MN-00-10-3, V. 106, Pt.2., American Society of Heating Refrigeration and Air-Conditioning Engineers, Atlanta, GA. Stevens, D.T; Lubliner, M; Davis, B. (1997) Mechanical ventilation in HUD-code manufactured housing in the Pacific Northwest. ASHRAE Transactions, 103 (1), pp. 693-705. TenWolde, A.; Burch, D.M. (1996) Ventilation, Moisture Control, and Indoor Air Quality in Manufactured Houses. Forest Products Laboratory, National Institute of Standards and Technology. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BAIHP Home | Overview | Case Studies | Current Data

Partners | Presentations | Publications | Researchers | Contact Us

Copyright © 2002 Florida Solar Energy Center. All Rights Reserved.

Please address questions and comments regarding this web page to BAIHP Master