Warning: The

following document contains patented intellectual property

of the University of Central Florida. Patents

pending: U.S. Application Serial No. 10/400,888, Provisional

applications 60/369,050 / 60/438,035 & UCF-449CIP; WhisperGuard (UCF-Docket

No. UCF-458)

Click here for PDF Version

Abstract

With

sponsorship from the U.S. Department of Energy, a research

project has designed, fabricated and tested improvements

to an air conditioner outdoor unit fan system. The primary

objective was to improve condenser fan performance while

reducing motor power. We also examined potential changes

to the condenser exhaust configuration to enhance air

moving efficiency performance. A secondary objective

was to provide sound reductions as lower noise AC equipment

is important to consumers.

Within

conducted tests, an improved high efficiency fan design

and advanced exhaust diffuser section reduced fan motor

power requirements by approximately 49 W (26%) while providing

superior air flow. When mated with a brushless DC motor,

the same configuration can reduce fan power use by nearly

100 Watts (55%). The overall increase to total system efficiency

(EER and COP) is approximately 2-4% depending on configuration.

The reduced fan unit power could be very desirable for

utilities concerned with peak demand, since the change

provides reliable load reductions on peak.

The

changes in exhaust configuration are also important in

that they allow for slower fan speeds to obtain equivalent

flow. When coupled with a developed vortex shedding control

strip and an asymmetrical fan design we showed reductions

to fan sound levels of 1-2 dB according to ARI Standard

270-1995.

Introduction

|

Figure 1. Typical 3-ton (10.6 kW)

air conditioner condenser

|

Air-cooled

condensers in residential air conditioning (AC) systems

commonly employ finned-tube construction to transfer heat

from the refrigerant to the outdoor air. As hot refrigerant

passes through the condenser coil, heat in the compressed

refrigerant is transferred through the tubes to the attached

fins. An electrically powered fan draws large quantities

of outside air across the finned heat transfer surfaces

to remove heat from the refrigerant so that it will be

condensed and partially sub-cooled prior to its reaching

the expansion valve. A conventional AC condenser and fan

is illustrated in Figure 1.

The

air conditioner condenser fan is one energy using component

of a residential air conditioning system. The largest energy

use of the air conditioner is the compressor. The other

components are the indoor and outdoor fans. Intensive research

effort has examined improvements to its performance. However,

much less effort has examined potential improvements to

the system fans. These include both the indoor unit fan

and that of the outdoor condenser unit.

Residential

air conditioners are a major energy using appliance in

U.S. households. Moreover, the saturation of households

using this equipment has dramatically changed over the

last two decades. In 1997, for instance, 73% of U.S. households

had air conditioning as opposed to 56% in 1978 (DOE/EIA,

1999). The efficiency of residential air conditioners have

large impacts on utility summer peak demand. Thus, improved

efficiency of air conditioning systems is both desirable

for consumers as well as utilities. One advantage of the

proposed research is that it will have small, but identifiable

impacts on system performance under peak demand conditions.

For

instance, if the condenser fan motor can be reduced in

size from 1/4 hp to 1/8 hp (0.79 to 0.09 kW), the approximate

drop in peak AC demand could amount to 100-150 Watts, depending

on motor efficiency. This translates directly to reduced

AC unit utility peak demand.

Background

The

outdoor condenser fan draws a large quantity of air (2,000

- 4,000 cfm) at low static pressure – typically 0.05

to 0.2 inches of water column (IWC) (12-50 Pa)through the

condenser coil surfaces. A typical 3-ton air conditioner

with a seasonal energy efficiency ratio (SEER) of 10 Btu/Wh

(SCOP = 1.93 W/Wh) moves about 2,400 cfm (1,133 L/s) of

air using about 260 Watts of motor power. The typical outdoor

fan and motor combination is an axial metal propeller type

fan inserted in a short diffuser with a fan efficiency

of about 20% - 25%; and a permanent split capacitor (PSC)

motor with a motor efficiency of about 55% - 60%. Typically,

a 1/4 hp (0.19 kW) motor would be used for a three ton

air conditioner (187 W of shaft power). The resulting air “pumping

efficiency” is roughly 11 - 15%. Lower condenser

fan electrical use is now available in higher efficiency

AC units through the use of brushless direct current (BDC)

permanent magnet motors and larger propellers. These changes

improve the overall air moving efficiency, but only about

20-25%.

A

literature survey revealed a number of studies evaluating

air conditioner condenser performance, but few examining

specific improvements to the outdoor fan.One investigation

did identify larger condenser fans as potentially improving

the air moving efficiency by a few percent (Proctor et

al., 1994). The same study also identified the need for

more efficient fan blade designs although it did not undertake

that work.

Currently,

major air conditioner manufacturers are working to maximize

the performance of conventional air conditioners to increase

cooling system efficiency in a cost effective manner. Within

this effort every watt of cost-effective power reduction

is potentially important. In this project we explored how

improvements to the outdoor unit propeller design as well

as reduction of the external static pressure resistance

of the fan coil unit could have large overall impacts on

potential efficiency.

|

Figure

2. Stamped metal condenser fan blades for a 3-ton

condenser |

Conventional

fan blades used in most AC condensers are stamped curved

metal blades that are inexpensive to manufacture, but may

not be not optimized in terms of providing maximum air

flow at minimum input motor power. See Figure 2.

For

instance, a typical 3-ton (10.6 kW) condenser fan from

one U.S. manufacturer draws about 260 Watts for a system

that draws 3,750 Watts overall at the ARI 95/80/67 test

condition. Thus, potentially cutting the outdoor fan energy

use by 30% - 50%

has the potential to improve air conditioner energy efficiency

by 2 to

3%.

Our

research attempted to design fan blade shapes with true

airfoils that would fit in conventional AC condensers (e.g.

19 inches wide for a three-ton condenser(10.6 kW) and 26" (66

cm) wide for a higher efficiency model). At the same time,

they were to provide good possible air flow at a design

rotational speed of 850 rpm with the lowest possible shaft

input wattage.

Fan

Performance

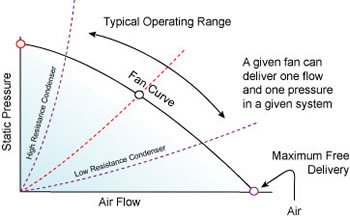

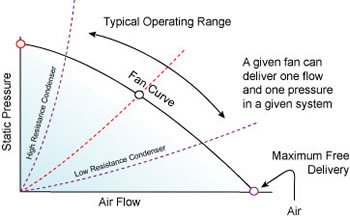

Condenser

fans, like all fans and propellers, are governed by fan

laws. Key implications of these laws are summarized in

the bullet items below and graphically illustrated in Figure

3.

|

Figure

3. Illustration of fan law impacts on air flow

in AC condenser

|

- The

system static pressure (negative pressure on the underside

of the fan and over-pressure above the fan) increases

at the square of the air flow increase.

- As

static pressure decreases, the air flow increases along

the fan curve for a given fan.

- Fan

curves can have peak efficiency and stall regions with

implications for air moving performance and sound.

- With

a given fan and system pressure, the air mass flow rate

increases linearly with fan RPM.

- PSC

motors offer limited RPM selection: 825-850 rpm for 8

pole motors, 1,075-1,100 rpm for 6 pole motors and 1,450-1,500

rpm for 4-pole motors. Slower motors are preferred due

to sound implications.

- Brush-less

direct current (BDC) permanent magnet motors offer variable

speed control to select the RPM range over the range

to which it is programmed. Thus, these motors allow flexible

choice of condenser fan air flow without sacrificing

efficiency.

One

challenge within the research was to adequately measure

the external static pressure of the fan as operating within

the condenser. As shown in Figure 3, establishing this

value was critical to the fan and the achievement of good

performance. Within our testing, this was measured under

the fan, taking a traverse of the condenser cavity using

a precision digital manometer. Measurement of the pressure

above the fan and under the grill proved more difficult,

but sufficient data was obtained to facilitate a fan design.

The total external static pressure of the original fan

producing ~2200 cfm (1,038 L/s) was about 30 Pa (0.12 IWC).

Impact

of Air Flow on Outdoor Unit Condenser

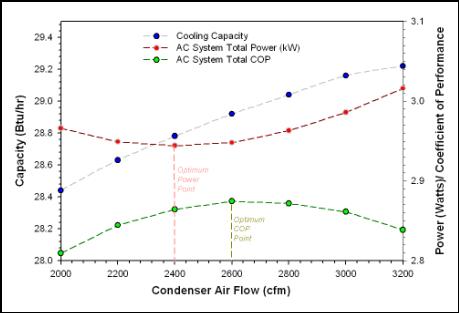

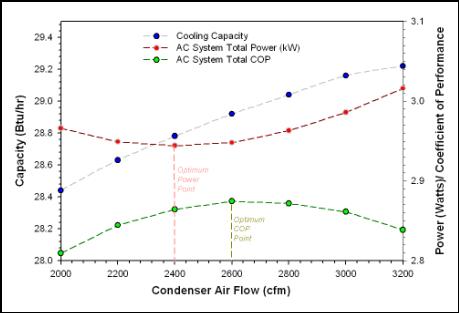

As

expected, greater air flows across the condenser coil heat

rejection surfaces lead to greater cooling capacity and

slightly lower compressor power. A simulation was run implementing

the DOE/Oak Ridge Heat Pump model to examine the relationship

between motor power and airflow for a conventional 3-ton

cooling system (Fischer and Rice, 1985). This simulation

model has been well validated (Levins et al., 1997 and

Rosenquist, 1997) and allows detailed examination of how

system cooling performance is enhanced by increased air

flow across the condensing surfaces and how this trades

off against increase to condenser fan motor power. Figure

4 shows the relationship evaluated for a conventional AC

system.

Figure 4. Evaluation of Optimum System Outdoor

Air Flow for a Hypothetical 3-ton air conditioner

Note

that the slope of the increased cooling system capacity

increases gradually with greater air flow, while the

required fan power increases rapidly with flow. As the

required shaft power will increase between the square

and the cube of the air flow, this exacts a real limit

on the air flow to be selected for a given condenser

design. Thus, the overall system electric power (including

compressor, and indoor and outdoor fans has an optimum

outdoor unit air flow where electric power is minimized

and another point where the system cooling coefficient

of performance (COP) is maximized. These two points are

close and between 2,400 and 2,600 cfm (1,133-1,227 L/s)

for the unit modeled. Not surprisingly, real AC units

of this size often have rated air flow of around 2,400

cfm (1,133 L/s).

It

should be noted, however, that the optimum condenser

coil face velocity and condenser air flow is affected

by the coil face area, coil depth and fin spacing (Green

and Roberts, 1996). Generally, the highest COPs are achieved

for coils with a large face area, operating at a high

evaporator temperature and a low air velocity (2 m/s).

However, as we had no control over the heat exchange

surfaces in the AC condenser in order to lower external

static pressure, the challenge for our research was to

design a fan and exhaust manifold for our test air conditioner

which would improve the overall air moving efficiency

and maintain or slightly increase flow.

Sound

Control

Although

improving condenser fan energy efficiency was the fundamental

goal of our research, a secondary objective was to reduce

sound levels due to the importance consumers place on

a quiet air conditioner. This is particularly important

with close lot lines where AC condensers can be near

to sleeping quarters in neighboring houses.

Sound

is measured in decibels (dB) above the background noise

level. As the scale is logarithmic, small changes can

mean large changes in sound level. For instance, 1 dB

is generally accepted as the minimum sound level difference

that people can discern. A change of 3 dB (20% change

in sound pressure) is noticeable and a 5 dB difference

is clearly noticeable. ARI Standard 270-1995 governs

the way in which sound levels are measured for outdoor

AC units.

The

importance of the sound issue is clearly illustrated

by a survey done of 550 individuals in Canada (Bradley,

1993) which found that complaints from air conditioner

noise dramatically increased when the sound level was

5 dB or more above background levels. Also, the same

survey found that homeowners expressed a willingness

to pay 12% more for a very quiet air conditioner.

Although

the topic of sound and vibration control within air

conditioning is quite complex, we describe here some

of the fundamental influences (Schaffer, 1991):

- Fan

rotation speed is a major factor in sound propagation

dB 1 = dB 2 + 50log 10 (rpm 1/rpm 2)

Thus, a fan moving at a 20% slower speed should exhibit

a 5 dB drop in sound level

- Other

factors:

- Vortex shedding: turbulent eddies in the wake of

the fan blade tips

- Turbulence due to the obstructions in the intake

or exhaust wake

- Fan motor vibration

- Harmonic resonance associated with the number of

blades

- Fan interaction with compressor noise

Within

our research, a key emphasis to reduce sound levels

was to operate fans more slowly with efforts made to

suppress fan tip vortex shedding and harmonic resonance

associated with fan blades.

Baseline Air Conditioning Unit

and Test Facility

For our testing, we used a

standard 3-ton (10.6 kW) air conditioning

system produced by a major U.S. manufacturer.

The system uses R-22 refrigerant, although

our evaluation was done with condenser

fan only operation. The system has

a rated SEER of 12 Btu/Wh (SCOP = 3.51

W/Wh) when mated with a compatible

evaporator and air handler. The 19" (48

cm) fan in the original outdoor unit

consists of four metal paddle blades,

powered by a six-pole 1/8th hp (0.09

kW) PSC motor with a rated flow of

2400 cfm (1,133 L/s) for the condenser.

As measured in the baseline condition,

the fan motor drew 190-197 Watts at

208 Volts and produced 2,180-2,200

cfm (1,029 - 1,038 L/s) turning a 1,010

rpm. At the 95/80/67 ARI test condition

the fan power for the entire AC system

represents about 6% of total system

power.

For the research, we

needed to accurately

measure power, condenser

air flow, fan motor

power and rpm as well

as environmental conditions.

Secondly, we desired

to measure sound levels.

For diagnostic purposes,

we also used flow visualization

tools (smoke pencils

and flow wands) to

aid our understanding

of the air flow dynamics.

An indoor test facility

was constructed. A

precision power transducer

provided motor power

measurements ( +1 Watt

resolution) and air

temperature and relative

humidity. As the facility

had 208 single-phase

power, this electrical

source was used for

the measurements involved.

A laser tachometer

was used to measure

fan rpm and a precision

portable dB meter was

used to measure nearby

sound levels. A digital

manometer was used

to measure static pressure

within the condenser

underneath the exhaust

fan. As condenser air

flow was a critical

measurement, we constructed

flow measurement chamber

in conformance with

ASHRAE Standard 51-1985.

The constructed outlet

duct chamber with flow

straighteners and settling

screens was then calibrated

at another facility

with NIST traceable

air flow equipment.

The final chamber was

estimated to yield

an absolute air flow

measurement accuracy

of approximately +

5% (125 cfm or 59 L/s).

The relative air flow

measurement accuracy

was much better. We

found the equipment

could reliably measure

changes in air flow

as small as 20 cfm

(9 L/s) out of a 2,500

cfm (1,180 L/s) air

flow.

Development

of New Fans

In designing

fans, our objective was

to create the most efficient

designs while operating

at low rotational speed

to reduce fan noise.

We also looked to create

robust characteristics

which would provide good

performance over a range

of static pressure. This

is important as pressure

rise can change as condensers

foul or due to heat pump

outdoor unit frosting

during winter operation.

Generally, the true airfoils

we used have flatter

fan curves than those

for curved metal bladed

fans.

Over

a period of two years, a total of five different fans

were designed and built (designated A-E) with a series

of sub-variations on each. The differing fan configurations

were targeted for differing rpm ranges, static pressure

rise and sound characteristics. The Original Equipment

Manufacturer (OEM) design was a stamped 3-bladed metal

fan. Fans A and D consisted of three equally spaced

blades, with tapered and twisted air foild. Fan D was

designed for a higher pressure rise. Fan A5 was an

asymmetrical 5-bladed design. Fan E had forward curved

blades, intended to assist with sound reduction. Each

of the designs were evaluated by computer simulation

and then produced as three dimensional coordinate files

that could be used to describe the complex shapes.

Rapid prototyping was used to physically produce the

fan blades. Each fan was then hand-mounted onto a produced

hub and speed balanced before evaluation on the test

stand.

|

Figure 5. 19" Fan A5 with

asymmetrical blade spacing. |

The

fan design with an asymmetrical alignment has unequally

spaced blades. This configuration was explored to potentially

lower noise levels. This technology has been previously

developed for helicopter rotors (Kernstock, 1999),

but not previously utilized for AC condenser fans.

The sound of air rushing through an evenly spaced fan

rotor creates a resonance frequency with the compressor’s

hum, leading to a loud drone. But if the blades are

not equally spaced, this resonance is reduced producing

lower ambient sound levels. With our invention, we

took advantage of the asymmetrical characteristics

using a five-bladed fan design where the

fan blades are centered unevenly around the rotating

motor hub (Figure 5).

We tested each fan design with 1/8 hp (0.09 kW) PSC motors

either with six poles rotating at approximately 1075

rpm or eight poles rotating at 850 rpm. Over one hundred

tests were conducted over an 18 month period.

Advanced

Diffuser Design

Diffusers

are an expanding duct which provides recovery of air

static pressure by reduction of the flow velocity as

the flowing air mass expands. Practically, the condenser

fan air velocity is lowered prior to exhaust, thereby

increasing the overall mass flow rate from the system.

The exhaust configuration of a standard unitary air

conditioner consists of a short 4" (10 cm), 10

degree divergent diffuser covered by a slotted grate

or wire grill with the fan is nestled in the bottom

of the diffuser section.

Examining interactions between high efficiency propeller

designs and external static pressure, we determined

that an optimized diffuser section would allow large

improvements in air moving efficiency. Diffuser theory

would suggest that large improvements in fan efficiency

are possible by lengthening the diffuser stage (Blevins,

1984). Theoretically, an 18"(46 cm) diffuser

should provide about 25% added pressure recovery

over that from a short 4" (10 cm) diffuser (Japiske

and Baines, 1993). While a longer length would provide

still greater pressure recovery, we judged an 18" (46

cm) height to be the maximum practical for consumer

acceptance.

Thus, we constructed a larger 18" (46 cm) tall

7o divergent diffuser with the motor and fan located

in the bottom of the assembly. Figure 6 shows the

overall assembly as produced with the elongated diffuser.

Essentially this modifies the overall fan design

from more of a shallow ducted propeller to a true

tube-axial design.

|

Figure

6. Diagram of the improved condenser fan

with enhanced diffuser. |

The

diffuser increases the exhaust diameter from 19.75" (50

cm) to 24" (61 cm) at the wire grill top. While

testing with an experimental stator stage did not

demonstrate any added flow, we did find other changes

in geometry to yield modest improvement. As the motor

occupies the center of the diffuser, the swirl set

up by the fan as it expands through the diffuser

tends to collapse on the low pressure zone immediately

behind the motor. Through trial and error, we found

that by using a smooth conical center body on the

other side of the motor, we could increase flow by

20 cfm (9 L/s) and reduce power by about 2-5 Watts.

Reducing Tip Clearances and

Sound Control

The functionality of an

air conditioner condenser exhaust

is essentially analogous to a ducted

fan. Research done over the last

twenty years within aeronautical

engineering has shown that tip clearance

of ducted fan blades to diffuser

walls is critical to performance

(Rajagopalan and Zhang, 1989; Abrego

and Bulaga, 2002).

Unfortunately, low tip clearances are practically

difficult in manufacture due to required tolerances.

Should fan blades strike a solid diffuser wall,

the fan blades or motor may be damaged or unacceptable

noise created. Thus, in air conditioner fan manufacturing,

the fan blades typically have a gap of 0.3 to 0.4

inches (0.8 - 1.0 cm) to the steel sidewall diffuser.

This large tip clearance has a disadvantageous

impact on the ducted fan’s performance.

Considering the desirability of low sound levels

for AC condensers we examined interesting work

done at NASA Langley Research Center showing how

porous tipped fan blades in jet turbofan engines

can provide sound control by reducing vortex shedding – a

known factor in the propagation of excessive fan

noise (Khorrami et al. 2002).

Based on the research, we postulated that rather

than porous fan tip, a porous diffuser sidewall

could achieve the same result. This was done by

obtaining commercially available 3/16" (0.5

cm) open cell plastic foam 1 ½" (3.8

cm) wide, and applying it to the inner wall of

the diffuser assembly swept by the fan blades.

In actual application a UV stabilized open cell

neoprene foam would likely be used. As shown in

Figure 6, the foam is applied within the diffuser

assembly over the swept blade region to breakup

fan blade tip vortices and reduce sound. We also

used a solid tip clearance strip to test the differences.

Whereas the solid strip actually increased fan

noise, the open cell foam strip reduced noise markedly

(see Table 1).

One added advantage was that the foam can be used

to produce very close tip clearances in ducted

fans with no danger to the moving blades. Any contact

with the foam inner liner will be quickly worn

away to yield ideal fan tip clearances. This was

verified in overnight tests where tolerances were

exceeded. A final advantage is simplicity and cost

effectiveness. This is a simple change that can

potentially produce large improvements in acoustic

and air moving performance.

We estimated the flow and sound impacts of the

invention by carefully measuring performance of

two fans. Sound levels from fan only operation

were measured using hand-held dB meters at the

prescribed distance used for ARI 270-1995 for

the horizontal measurements. The results in the

Table 1 show a large improvement in airflow as

well as sound advantages.

Table

1

Impact on Performance of Reduced Tip Clearance

Using Foam Sound Control Strips |

|

|

Case |

Flow |

Power |

Normalized

CFM/W |

dBA |

OEM

Fan with slotted grill (1000 rpm) with

standard diffuser and top

|

Original

Configuration |

2200

cfm |

190

W |

11.6 |

63.0 |

A5

Fan with 8_pole motor (850 rpm) with extended

conical diffuser |

As

is (~1/4" clearance)

Tip clearance <1/32" foam |

2110

cfm

2300 cfm |

135

W

141 W |

15.6

16.3 |

62.0

60.0 |

A

Fan with 6 pole motor (1100 rpm) with conical

diffuser

|

As

is (~1/4" clearance)

Tip clearance <1/32" foam |

2400

cfm

2610 cfm |

139

W

145 W |

17.3

18.0 |

64.5

61.0 |

Note

the improvements in air moving efficiency. As the

shaft power requirement increases between the square

and the cube of the flow quantity, the advantage

of the foam strip for A5 (2,110 to 2,300 cfm) represents

a measured improvement in the air moving efficiency

of nearly 23%. Moreover, at three feet (1m) away

from the condenser, we measured sound reductions

of at least approximately two decibels (15% more

quiet to the human ear). In contrast, we had previously

attempted a number of other suggested improvements

(forward swept blades, dimpled air foils and winglets)

which did not produce any measurable sound reduction.

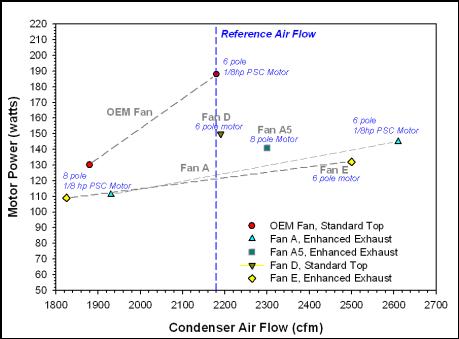

Tests Results

The fans were evaluated

with the standard slotted grill top

and later with the improved diffuser

configuration (elongated diffuser

with foam tip clearance strip and

conical center body). We also tested

with differing PSC motors (six vs.

eight pole operating at 1075 and

850 rpm, respectively). The process

involved measuring performance and

then evaluating the changes in a

comparative manner to isolate the

best options. The best performing

configurations with and without the

enhanced exhaust are summarized below.

Table 2 provides numeric data and

Figure 7 shows the graphical results.

Table

2

Comparative Performance of Fans & Diffuser

Elements |

| |

| |

Top |

Fan |

Motor |

Flow

(cfm) |

Power

(W) |

CFM/W |

Sound

(dBA) |

| * |

Slotted

Slotted

Slotted |

OEM

D

A5 |

6-pole

6-pole

8-pole |

2200

2190

1660 |

190

150

130 |

11.2

14.6

12.8 |

63.0

65.0

62.0 |

| ** |

Diffuser

Diffuser

Diffuser

Diffuser

Diffuser

Diffuser

Diffuser |

OEM

A5

A

A

E

E

D |

6-pole

8-pole

8-pole

6-pole

6-pole

8-pole

6-pole |

2250

2300

1930

2610

2500

1825

2590 |

173

141

111

145

132

109

150 |

13.0

16.3

17.4

18.0

18.9

16.7

17.3 |

63.0

59.0

58.0

66.0

65.0

61.0

66.0 |

| *** |

Wire-foam

Wire-foam |

OEM

A5 |

6-pole

8-pole |

2250

2110 |

188

146 |

12.0

14.5 |

62.0

60.0 |

*

Standard configuration, metal bladed fan |

**

Preferred configuration, with advanced fan

and diffuser with foam tip clearance strip |

***

Preferred configuration with standard top,

wire grill and foam control strip |

|

Figure

7. Performance of different fans with and without

the enhanced diffuser against the original

configuration |

Results

are shown for each fan, both with the slower 8-pole

motor (850 rpm) and the faster 6-pole motor (~1075

rpm). The best performing fan with the standard slotted

grill top and short diffuser was the three-bladed

Fan D which was designed for a higher pressure rise.

It produces the same flow as the standard OEM fan

(~2200 cfm or 1,038 L/s) with a power consumption

of 150 W vs. the 190 Watts for the standard fan at

208 Volts. Sound levels are similar to the standard

configuration.

We

also did a test of the original configuration

with a wire grill rather than slotted

top above the short diffuser. The

wire grill showed superior performance– likely

due to a lower pressure rise above

the fan. The power of the original

metal-bladed fan dropped by 2 Watts

with equivalent flow. When the foam

tip clearance strip was added to

the original short diffuser, flow

increased by 50 cfm (24 L/s) along

with a small drop in sound level.

Also shown are tests using the

enhanced diffuser with Fan A, Fan

A5 (a 5-bladed asymmetrical version

of Fan A) and Fan E. Two fans (B

and C) are not shown as results

were not promising.

Note

that the A5 fan with the diffuser improves air moving

efficiency (CFM/W or L/s/W) by greater than 46%. With

the enhanced diffuser, this was our preferred configuration.

It produced 100 cfm (47 L/s) more flow than the standard

configuration while still reducing power by 49 Watts.

Unlike Fan D, it also reduces sound since the enhanced

diffuser allows the use of a slower turning fan with

an 8-pole motor to achieve better flow. Fans A and

E allow superior flow over the original configuration

at even lower power, although sound levels are increased.

These results suggest that a fan such as A5 could be

run at even lower RPM using a variable speed motor

to provide greater power and sound reductions or conversely

run at higher RPM to provide greater flows.

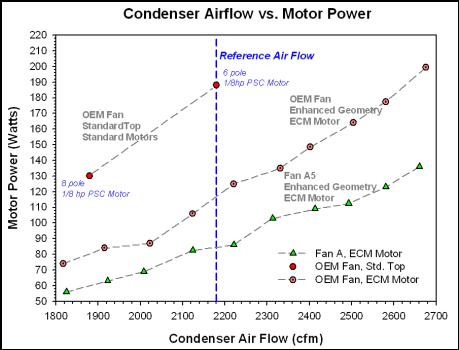

Tests

with a Variable Speed Motor

To

examine how the new fan and diffuser designs would

compare with the standard design at a given flow, we

obtained a brushless direct current (BDC) 1/3 hp (0.25

kW) motor from a leading U.S. manufacturer. It was

programmed to be variable in speed from 0 - 1200 rpm

in response to a pulse width modulated DC signal. These

motors tend to be more efficient than PSC motors– by

approximately 15% at full speed, but with large differences

at lower speeds. Our tests verified these expectations

and also showed the full advantages of the air foil

fan designs as well as the enhanced diffuser when flow

was equivalent to the OEM design.

For instance, the OEM fan with the standard top and

1/8 hp (0.09 kW) PSC motor required 190 Watts to

provide 2,200 cfm (1,038 L/s) of flow at 208 Volts.

The original fan with the enhanced diffuser and the

BDC fan required 125 Watts to provide the same flow

(2200 cfm). Thus, the diffuser and the BDC motor

produced a power savings of 65 Watts or 34%. However,

Fan A5 with the enhanced diffuser, and BDC motor,

only required 86 Watts to provide the same flow – a

reduction in power of 102 Watts or 55%. The same

tests also showed that by increasing rpm with the

A5 fan up to 1,060 rpm, flow was increased to 2,410

cfm (1,137 L/s) with 106 W power draw.

Within our research, we established that modulating

outdoor unit fans speeds may have attractive performance

and sound tradeoffs. We speculate that much of the

nuisance of air conditioner noise comes during nighttime

when ambient sound levels are low and occupants are

asleep. This suggests that the BDC condenser fan

speed might be modulated to high speed during very

hot daytime periods. For instance, fan speed could

be set to high above 94oF (34oC) while a low speed

would be used when the outdoor temperature wa less

than 84oF (29oC). This would substantially reduce

fan noise during evening hours while preserving best

peak performance during hot afternoons. Figure 8

below shows the comparative performance of the OEM

configuration, the OEM fan used with the enhanced

diffuser, and BDC motor with the improved fan design.

|

Figure

8. Impact of BDC motor and improved fan blades

on condenser performance. |

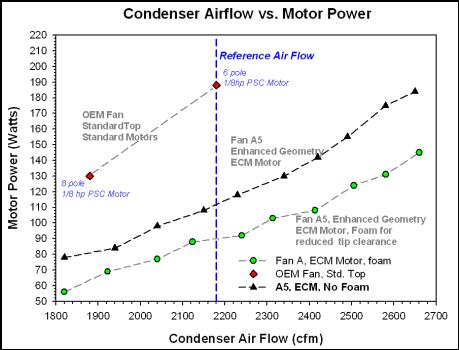

In

Figure 8, the impact of the diffuser and BDC motor

can be seen as well as the influence of the improved

fan blades. Finally, Figure 9 below isolates the airflow

improvement created by the tip clearance and sound

control foam strip when evaluated at differing flow

points with the BDC motor and the high performance

fan.

|

Figure

9. Impact on performance of Fan A5 used with

elongated diffuser with and without tip clearance

foam strip. |

Additional

Laboratory Measurements

In May 2004, we took

the prototype condenser top to a major U.S. air conditioning

manufacturer who possessed a sound room and air flow

measuring facilities to allow verification of measurements.

Within their laboratories, we found that measured

sound reductions of the new diffuser top were only

1-2 dB as measured according to the ARI 270-1995 standard.

This is likely due to the tendency of the longer

diffuser to broadcast sound upward to the overhead

microphones. We also were able to verify the flow

and power reductions previously measured. Power consumption

of the PSC motors, when tested at 230 volts was about

10 watts more than test done at 208 volts. However,

the savings with PSC motors at 230 volts could be

made similar to what we measured by slightly reducing

the shaft wattage of the motors for the improved

blades. This would reduce power waste as the motors

approach synchronous speed at higher voltage.

Conclusions

A research project designed,

fabricated and tested high efficiency

air conditioner condenser fans to

improve flow characteristics while

dropping motor power. We also examined

potential changes to the condenser

exhaust configuration to enhance

performance. The primary objective

was to reduce motor power while providing

similar or superior flow to the standard

configuration. A secondary objective

was to provide sound reductions which

is important to consumers.

Within the effort, we developed new twisted and

tapered propeller air foils that demonstrated greater

air moving efficiency. Fan only savings were 40

watts (21%) for the same motor and condenser top.

We

also showed how a lengthened diffuser with a conical

insert after the motor can improve air moving efficiency

by over 16% for standard fans and over 27% for high

performance fans. Fan tip losses and associated vortex

shedding was reduced though the use of a porous foam

strip to improve air flow performance while helping

to reduce sound. This also allows slower fans to

provide superior air moving performance along with

sound control. On the negative side, however such

design would lengthen condenser height by approximately

18" (46 cm) and somewhatincrease costs by increasing

sheet metal requirements.

The

fundamental project achievements are summarized below:

- Provides

49 Watt reduction in fan power (141 W vs. 190 Watts)

with PSC motors at 208 volts.

- Increases

condenser air flow by 100 cfm or 47 L/s (5% increase

in fan flow).

- Provides

102 W power reduction with BDC motor.

- Reduces

fan-only ambient sound level by 1-2 dBA. Ground level

sound reduction is greater.

- BDC

motor allows lower fan speeds for ultra-quiet night

operation, higher flows for maximum capacity during

very hot periods (temperature based control)

Key Technologies

- High

efficiency 5-bladed asymmetrical fan moves air

quietly at lower fan speeds.

- Diffuser

top for effective pressure recovery allowing increased

air flow at low speeds.

- Conical

center body reduces losses in exhaust swirl.

- Foam

sound control strip to reduce tip losses and fan

tip vortex shedding.

- Patents

pending: U.S. Application Serial No. 10/400,888,

Provisional applications 60/369,050 / 60/438,035 & UCF-449CIP; WhisperGuard (UCF-Doc

Acknowledgments

This work was funded by the U.S. Department

of Energy within its Building Technologies Division.

Thanks to Terry Logee for his support. Gary Nelson

and Ron Rothmann with The Energy Conservatory assisted

with development and calibration of the air flow

measurement equipment. At AeroVironment, Inc. John

Gongola and Guan Su assisted with creation of the

computer generated designs. In particular, we appreciate

the great skill of Shep Shepperd of Merritt Island,

FL in provided the precision machining to assemble

the prototypes and exhaust manifold configurations.

References

A. I. Abrego and R. W.

Bulaga, “Performance Study

of a Ducted Fan System,” NASA

Ames Research Center, American Helicopter

Society Aerodynamics, Acoustics and

Test Evaluation Technical Specialists

Meeting,” San Francisco, CA,

January 23_25, 2002.

ANSI/ASHRAE 51-1985 (Revision: ANSI/ASHRAE 51/AMCA

210_1999): Laboratory Methods of Testing Fans for

Rating, American Society of Heating, Refrigerating

and Air Conditioning Engineers, Atlanta, GA.

ARI, 1995. ARI 270-1995: Sound Rating of Outdoor

Unitary Air Conditioning Equipment, Air Conditioning

and Refrigeration Institute, Arlington, VA.

ASHRAE, 2004, “Chapter 18: Fans,” HVAC

Systems and Equipment, American Society of Heating,

Refrigerating and Air Conditioning Engineers, Atlanta,

GA.

R. D. Blevins, Applied Fluid Dynamics Handbook, “Nozzles,

Venturis and Diffusers,” Van Nostrand Reinhold,

NY, 1984.

J. S. Bradley, 1993, “Noise from Air Conditioners,” Institute

for Research in Construction, National Research

Council of Canada, Ottawa, ONT.

DOE/EIA, 1999. A Look at Residential Energy Consumption

in 1997, Energy InformationAdministration, DOE/EIA-0632

(97), Washington, DC.

S. K. Fischer and C. K. Rice, 1983. The Oak Ridge

Heat Pump Models: I. A Steady_State Computer Design

Model for Air_to_Air Heat Pumps, ORNL/CON_80/R1,

Oak Ridge National Laboratories, August, 1983

R. H. Green and L. Roberts, 1996. “The Effect

of Air-Coil Design on the Performance of Heat Pumps

and Air Conditioners,” ASHRAE Transactions,

Vol. 102, Part 1, pp.257_265.

D. Japikse and N.C. Blaines, 1993. Diffuser Design

Technology, Concepts ETI, Inc., White River, VT.

M. R. Khorrami, F. Li and M. Choudhari, 2001. “A

Novel Approach for Reducing Rotor Tip Clearance

Induced Noise in Turbofan Engines” NASA Langley

Research Center, American Institute of Aeronautics

and Astronautics, 7th AIAA/CEAS Aeroacoustics Conference,

Maastrictht, Netherlands, 28_30 May, 2001.

Nicholas C. Kernstock, “Slashing through

the Noise Barrier,” Aviation Today, August

1999.

W. P. Levins, C.K. Rice, and V. D. Baxter, 1997. "Modeled

and Measured Effects of Compressor Downsizing in

an Existing Air Conditioner/Heat Pump in the Cooling

Mode," ASHRAE Transactions, Vol. 192, Part

2, pp.22_33.

J. Proctor, Z. Katsnelson, G. Peterson and A. Edminster,

Investigation of Peak Electric Load Impacts of

High SEER Residential HVAC Units, Pacific Gas and

Electric Company, San Francisco, CA., September,

1994.

R. G. Rajagopalan and Z. Zhang, "Performance

and Flow Field of a Ducted Propeller," American

Institute of Aeronautics and Astronautics, 25th

Joint Propulsion Conference, AIAA_89_2673, July

1989.

G. J. Rosenquist, 1997. "Comparison of Simulated

and Measured Test Data on Air_Source Heat Pumps",

3rd International Conference on Heat Pumps in Cold

Climates, Wolfville, Nova Scotia, Canada, Aug.

11_12, 1997; Caneta Research, Inc., Mississauga,

Ontario, Canada, November, pp.391_405.

M.

Schaffer, 1991. A Practical Guide to Noise and Vibration

Control for HVAC Systems, ASHRAE, Atlanta, GA.

Click

here for PDF Version

|