|

II.

BAIHP Technical Assistance (B-C)

- Bellview

Air

Gainesville, Florida

Florida H.E.R.O. discussed a range of issues with Bellview

Air, including the impact of input data on Manual J equipment

sizing and the air handler location in an effort to improve

indoor air quality, comfort, and energy performance.

The potential benefits of unvented cathedralized roof

systems were also addressed. Construction anticipated

in late 2005.

- Bobek

Building Systems

Oviedo, Florida

|

Figure

7 1800 sq.ft.

Steel

Frame

Residence near Oviedo, Florida. |

BAIHP

conducted a testing visit to new BAIHP partner. Bobek

Building Systems building exclusively with steel frame

and partial panelized construction (Figure 7)

to measure whole house and duct leakage and to evaluate

envelope insulation with IR camera. BAIHP compiled the

results of the testing and sent design recommendations

to the builder.

Table

8 Air Tightness Testing |

Blower Door Test Results |

Duct System Airtightness |

CFM50 = 1693 |

CFM25total = 285 |

ACH50 = 7.05 |

CFM25out = 42 |

C=157.8, n=0.607, r 2=0.999 |

Qn = 2.3% |

Duct testing shows low leakage to out (2.3%) but an excessive

level of total leakage. The ducts are located in the attic

which is largely sealed (essentially unvented) with an insulated

steel panel roof deck. During blower door testing, the attic

space was found to depressurize to 13 pascals while the home

was at -50 pascals, showing the space is better connected

to the conditioned space than to the outside. One known area

of attic leakage to outdoors occurs at the front porch overhang.

The high total duct leakage should be addressed to ensure

proper distribution and mixing. In many cases this is caused

by leakage where the supply register ties into the supply

boot. Supply registers with integral foam seals are recommended

to provide a tight fit at the boot connection and where the

register meets the ceiling surface.

Infrared Imaging

|

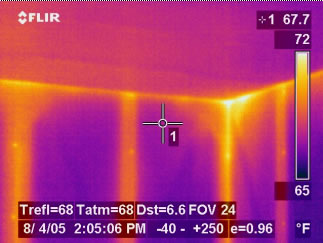

Figure

8 Thermal Image

of

Exterior, Steel-framed

Walls

|

The

IR picture in Figure 8 shows a corner, side and

front wall from inside the home. This picture is typical

of IR images from inside the house perimeter. Portions of

the wall shown violet in color reflect an indoor temperature

of approximately 67º. Lighter and brighter colors indicate

higher temperatures. Metal studs and points of joining between

the ceiling and side walls can be seen in orange and light

yellow.

As

can be seen from the IR picture, thermal shorts exist between

the outdoor and interior space. Though the overall differential

between room temperature and stud temperature is relatively

small (5ºF), the cumulative effect may

represent a significant conduction load on the space conditioning

system. Reducing thermal bridging between outside and inside

the home will reduce thermal loading taking place inside

the home. This, in turn, will reduce air conditioning run

times.

BAIHP Recommendations included:

- Sealed supply and return registers to reduce total duct

leakage and improve distribution efficiency

- More attention to sealing the attic space from outdoors

since this is essentially a buffer to the conditioned interior

space. This will also lessen any duct leakage to outdoors.

Additionally,

some method of breaking the thermal short between the stud

and the back of the drywall should be deployed in future

construction efforts. Consideration should be given to

applying foam board, ¾” minimum, between

the stud and the drywall. At a minimum, application of adhesive

backed foam strips applied to the stud prior to drywall installation

should be considered.

- Cambridge

Homes

Orlando, Florida

Category B, 1 Home

Note 100% Energy Star Builder

|

Figure

9 The Augusta,

Cambridge Homes BA Prototype |

This BAIHP partnership resulted in continuation of monitored

field research in the Augusta Building America model (Figure

9) and a control home. See BAIHP Research (Section

III), Site Built Housing Research, Cambridge Homes.

In November 2004, BAIHP participated in a meeting with

this partner to discuss water damage incurred in recently

built homes as a result of the 2004 active hurricane

season. Approximately 12 people took part in the meeting

including BAIHP researchers, and Cambridge Homes design,

construction, and architecture personnel.

Results

of field investigations were shared, and potential solutions

discussed.

During the 4 th budget period in cooperation with the

University of Central Florida Industrial Engineering

Department (UCFIE), FSEC researchers tested four Cardinal

modular homes with the Cardinal sales manager and plant

quality engineer. Initial results found that peak loads

for heating were almost double that for cooling. All

four of the homes had leaky ducts. These leaks accounted

for the largest peak load in the homes, averaging 28%

of the winter peak and 21% of the summer peak.

- Champion

Homes

Washington (state)

Champion

Homes built the first stress skin insulated panel (SIP) manufactured

home now sited in western Washington. The house air tightness

was measured at ACH50=3.55, well below the average numbers

for all homes previously tested in the WSU random home study

(see Northwest Energy Efficient Manufactured Homes). Energy

savings are estimated at 50% greater than a home constructed

to the HUD Code. These results were presented at the 2003

ASHRAE Summer Meeting, authored by Pacific Northwest National

Laboratory (PNNL), with contributions from BAIHP staff.

- City

of Gainesville, Cedar Grove II

Gainesville, Florida

Category B, 139 Homes

Award: HUD award for Innovation in Housing in 2004

|

Figure

10 City of Gainesville

house in Cedar Grove II |

Florida

H.E.R.O. began working with the City of Gainesville before

the ground-breaking in the Cedar Grove II subdivision of

HUD housing. Project manager Judy Raymond envisioned a

new urban style development (HUD’s first) with

single family homes featuring high quality construction

and individualized character with front porches and front

façade details (Figure 10). She worked

with Florida H.E.R.O. to develop engineered plans for

mechanical and air distribution systems and a whole house

package that was recognized with a HUD award in 2004. Table

9 summarizes the specifications.

Table

9 City of Gainesville, Cedar Grove II Subdivision,

HUD Home |

Component |

Specification |

Conditioned Area |

~1200-1400 (139 units) |

HERS Rating |

86-88 (goal = 86) |

Cooling And Heating |

SEER 12 with hydronic heating;

some 80% AFUE furnaces with programmable thermostat. |

Duct System |

Ducts in conditioned space.

Ducts moved to attic in later phase. Return duct and

air handler still conditioned space.

Duct system engineered

using Manual D, sealed with mastic, all homes performance

tested for duct air tightness. CFM25 out≈25

|

System Capacity |

Cooling and heating systems

sized using Manual J calculation procedure |

Walls |

R-13 cellulose |

Ceiling |

R-30 cellulose insulation

with radiant barrier |

Windows |

Double pane metal frame |

- City

of Orlando, The Orlando House

Orlando, Florida

Category A, 1 House

|

Figure

11 The Orlando

House |

The

City of Orlando, through the office of Housing and Community

Development in the Planning and Development Department,

constructed an environmentally friendly demonstration home

called The Orlando House: Florida’s

Future, on an infill site within the city (Figure

11). The City requested FSEC assistance to assure

the home met Building America goals and the Florida Green

Home Designation Standards. Ground broke on the demonstration

home in December 2001 and the home was open to the public

for community education purposes for approximately one

year. Specifications are listed in Table 10.

The City acquired more than $100,000 in donated materials

and services for the project, and completed much of the

construction using their own staff. Along with public

education, a primary purpose for this project was to

give the city staff first hand experience in the use

of green building materials and techniques - especially

those relating to energy efficiency, indoor air quality,

durability, disaster mitigation, and termite resistance.

That experience would allow the products and techniques

to be effectively used in future low-income housing constructed

by the city.

Table

10 City of Orlando – Orlando House |

Component |

Specifications |

Conditioned Area |

2148 sq. ft. |

HERS Score |

88.3 |

Envelope |

Above-grade Wall Structure |

Steel Frame 1 st and 2

nd floors |

Above-grade Wall Insulation |

R-19 Icynene |

Exterior Wall and Roof

Sheathing |

OSB - Borate treated |

Attic |

Unvented R-19 Icynene |

Roof |

Metal |

Windows |

Double pane Low-E |

Equipment |

Heating & Cooling |

13 SEER heat pump |

Thermostat |

Programmable |

Ventilation |

Passive outside air vent |

Water Heater |

50 gal, EF=0.88 (Electric) |

Lighting |

100% fluorescent |

Appliances |

Energy Star |

Additional Green

Features:

- Termi-mesh

- Safe Room

- VOC source control

- Resource efficient interior finishes

|

- Durable exterior finishes

- Ultra-low-flow water fixtures

- Low water using landscape

- Pervious driveway/walkway

|

One particular focus of this project was disaster resistance.

For protection from wind storms, a durable steel structure

was used along with a safe room located in the detached

garage. For termite resistance, all structural and exterior

finish materials were selected on the basis of providing

the least amount of available food source. Materials

such as borate treated lumber and sheathing, steel structural

components, and plastic/composite finishes were used

extensively in conjunction with a Termi-mesh barrier

system.

FSEC

certified the house for the Florida Green Home Designation

Standard in February 2003. FSEC staff also presented information

regarding Florida Green Home Designation as part of a builder

training event held at the Orlando House. Two CEUs were

available to attendees, and approx. 30 people attended

from the central Florida area. Training also included talks

on Zero Energy Homes, Florida Sun Built Program, and a “builder panel” that

included 3 BAIHP partner builders.

The demonstration home was sold in May 2003, and money

acquired from the sale will go directly towards the construction

of low income housing that utilizes several green building

techniques.

- City

of Lubbock Community Development

Lubbock, Texas

|

Figure 12 Low income

housing

built

by the City of Lubbock using

insulated

concrete forms.

|

Through the Portland Cement Association (PCA), contact

was established with the City of Lubbock who is building

low income houses with insulated concrete form (ICF)

systems (Figure 12). FSEC researchers visited

Lubbock twice to conduct diagnostic tests and provide

training and technical assistance. FSEC also conducted

initial HERS ratings on four Lubbock Habitat for

Humanity (see Habitat for Humanity, Texas) homes

plans and introduced the Habitat affiliate to the

City of Lubbock’s

other low-income housing activities.

- Clayton

Homes

Waycross, Georgia

FSEC personnel conducted a plant visit of the Clayton

Homes factory in Waycross, Georgia in June 2002. A singlewide

home was tested and observations recorded of home and

duct construction techniques. Findings and remedies for

leaky ducts found during the visit were reported to factory

representatives in a follow-up trip report (see Appendix

A).

|

You

are here: >

You

are here: >