|

II.

BAIHP Technical Assistance (N)

- Nez

Perce Fish Facility

Cle Elum, Washington

Three SGC homes were built at the Nez Perce tribal fish

facility in Cle Elum, WA. One of these homes is equipped

with Energy Star appliances and lighting; all three homes

are heated with Insider heat pumps. Monitoring equipment

was installed in Year 2. In Year 3, preliminary blower

door testing indicated a high leakage rate. During Year

4, tests found significant duct leakage due to failure

of butyl tape at risers on 2 year old home. (See also Section

III Research Zero Energy Manufactured Home.)

- New

Generation Homes

Ft.

Myers, FL

|

Figure 31 New Generation

Home |

Ken Kingon of New Generation Homes became

a BA partner at the end of the 5 th budget period.

Of particular interest is the performance of the high

efficiency 5 ton 15 SEER AC system and the use of outside

air ventilation (measured air flow = 32 cfm) to the

air handler. A house was tested and instrumented in

February 2005 by FSEC researchers, showing that duct

leakage and air tightness are consistent with new home

construction, there are opportunities for improvement.

The HERS score is 87.9.

- Northwest

Energy Efficient Manufactured Housing Program (NEEM)

Idaho

Oregon

Washington (State)

The Washington State University Energy Program (WSU),

together with partners Oregon Office of Energy and Idaho

Department of Water Resources, Energy Division, continue

to provide technical and research support to the Northwest

Energy Efficient Manufactured Housing Program (NEEM program

in the Pacific Northwest. The NEEM program involves 20

plants in three states, hundreds of retailers and thousands

of homebuyers.

The NEEM program includes the brands Super Good Cents

and ENERGY STAR, and includes homes heated by electricity

and Natural Gas/propane. Prior to 2003, the NEEM program

also included the Natural Choice brand, which was exclusive

to homes heated with Natural Gas or propane. In 2003,

the Natural Choice brand was phased out; now, all gas

heated homes are branded ENERGY STAR. In 2004, a new

path for ENERGY STAR was developed for Super Good Cents

homes with electric furnaces. Homes will be built to

this path beginning in 2005.

In the fall of 2004, NEEM staff began to provide technical

assistance to Champion Homes on a 700 unit private military

modular housing development at Ft. Lewis. In-plant verification,

certification and on-site verification of these homes

began in spring of 2005 and will continue as a major

BAIHP effort.

In the fall of 2004, technical assistance by NEEM staff

to the Energy Trust of Oregon resulted in the development

of a million dollar utility incentive program that promotes

the production of a more NEEM homes built to higher benchmarking

levels consistent with BAIHP goals. A technical analysis

of the ETO program has been provided to FSEC.

Throughout the BAIHP effort, WSU staff provided technical

assistance and guidance to the NAHB Research Center Energy

Value Housing Awards, judging submittals, providing de-briefing

to builders, and participating on workshops. NEEM builders

Fleetwood, Champion, Valley and Marlette have received

EVHAs for factory built housing.

Aligning with New Building America Goal

In

the summer of 2004, BAIHP staff performed a benchmarking

evaluation to assess the improvement of NEEM homes over

the entire BAIHP project period (note that this evaluation

was included in the Year 5 (April 2003 – March

2004) annual report). The benchmarking was based on

a home defined by NREL (built to IECC requirements).

The savings over the benchmark home were estimated

using version 2.2 of Energy Gauge USA. Evaluations

were performed for a typical 1600 ft 2 double wide

home with 12% glazing to floor area (the NEEM fleet

average) in three Pacific Northwest climate zones:

Portland, OR; Spokane, WA; and Missoula MT.

The homes were benchmarked assuming a continuously

operating whole house ventilation system, resulting in

a significant thermal energy penalty. Additional benchmarking

was also conducted using the 164 kWh/year ventilation

assumption in the NREL benchmark, in an effort not to

penalize the homes for improved IAQ associated with HUD

whole house ventilation system requirements and ASHRAE

62.2.

In 2004-2005, improvements were made to NEEM HVAC systems

and duct specifications as a result of BAIHP research

(see Refinement of NEEM Specifications, below.) Additional

benchmarking is presented that reflects these improvements.

The results of the benchmarking vary considerably by

HVAC type, water heat and climate, as noted in Table

19 below. Some key observations:

- In all climate zones, electric homes result in negative

savings if the ventilation penalty is assumed.

This is largely the result of the assumption that

the benchmark home has a heat pump that performs without

installation problems; an assumption that will be

evaluated by BAIHP research.

- Gas heated NEEM homes came closest to meeting the

overall BAIHP goal of 40% over the NREL

benchmark, but only met the goal if gas heat is paired

with electric water heat, in cold climates with no

ventilation system penalty.

- Eliminating the ventilation system penalty has a

higher impact on benchmarking results (9

to 23 percentage points) than improved duct leakage tightness

(3 to 11 percentage points).

- It should be noted that

Benchmarking these NEEM homes against the HUD-FMCSS requirements

(Uo=.079) for manufactured homes rather than the

IECC (Uo=0.06) would yield considerably higher savings

than current benchmark assumptions.

Table

19 Benchmarking Savings Results |

Duct Leakage |

Pre-2004* |

2004** |

Pre-2004* |

2004** |

Ventilation System Penalty |

Yes |

Yes |

No |

No |

Portland |

Electric Furnace |

-31 |

-20 |

-8 |

0 |

Heat Pump |

11 |

14 |

20 |

22 |

Gas Heat/Elec DHW |

16 |

22 |

32 |

37 |

Gas Heat/Gas DHW |

15 |

20 |

30 |

34 |

Spokane |

Electric Furnace |

-18 |

-9 |

2 |

10 |

Heat Pump |

17 |

21 |

27 |

30 |

Gas Heat/Elec DHW |

22 |

27 |

36 |

41 |

Gas Heat/Gas DHW |

21 |

26 |

35 |

39 |

Missoula |

Electric Furnace |

-12 |

-3 |

8 |

15 |

Heat Pump |

17 |

22 |

28 |

32 |

Gas Heat/Elec DHW |

21 |

26 |

35 |

40 |

Gas Heat/Gas DHW |

20 |

25 |

34 |

38 |

*

Pre-2004 – Duct

leakage of -132 cfm@25PA

** 2004 – Duct leakage

of -60 cfm@25PA

|

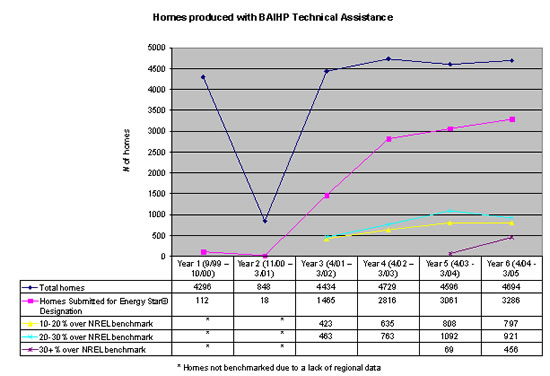

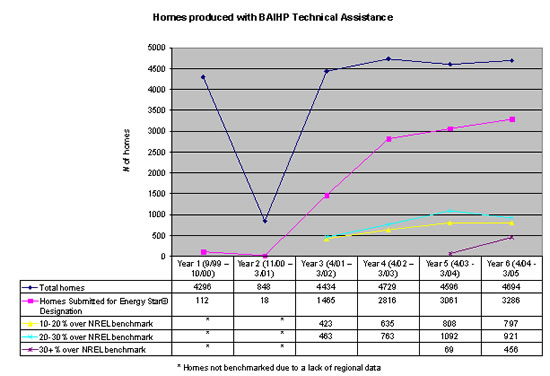

Figure 32 shows, by program year,

the number of homes produced with technical assistance from

BAIHP, as well as the number of homes submitted for ENERGY

STAR designation by BAIHP staff and the breakdown of homes

by benchmarking score. Please note the following:

- The benchmarking includes the assumption, based

on the NEEM 5 th Budget Period random that

showed 24% of all homes included after-market heat

pumps.

- No benchmarking was performed for Years 1 and 2,

due to a lack of accurate regional data.

- In 2003 and 2004, the appearance of homes that achieved

a 30+% benchmark is the result of the improvements

made to the NEEM HVAC specifications.

- Figure 32 averages benchmarks for Spokane and Missoula

for homes in cold climates and uses the

Portland benchmark for marine climates. Figure 32 also

assumes an average value between ventilation penalty

and no ventilation penalty.

The continued success of the program is due to several

factors. BAIHP and NEEM staff worked to increase awareness

within the manufactured housing industry of the marketing

value of energy efficiency, increase participation by

utilities in incentive programs, and promote the co-branding

of NEEM with ENERGY STAR.

Figure 32 Homes Produced

with BAIHP Technical Assistance

The

increase in ENERGY STAR designations is due to refinement

of the SGC duct sealing specifications, resolving a discrepancy

between the SGC specifications with ENERGY STAR’s duct

sealing protocols (while this question was being resolved

September of 1999 through early 2001, BAIHP staff did not

submit homes to DOE for ENERGY STAR designation). In 2003,

remaining discrepancies with manufacturers in Idaho were

further resolved, allowing BAIHP staff to accurately report

all qualifying homes.

Refinement of SGC specifications

BAIHP staff continually work to refine the existing SGC

specifications, a result in large part to innovative building

technologies researched in BAIHP.

In 2003, BAIHP staff worked with NEEM staff and manufacturers

to develop revisions to NEEM specifications, including allowing

only mastic for duct sealing, requiring metal flex duct for

whole house ventilation fans, and changing the air infiltration

specification from 7.0 ACH 50 to 5.0 ACH 50.

The revised specifications were voted on and accepted by

the manufacturers; they took effect on January 1, 2004.

In

year 2004 in Oregon, 1 in Idaho plant began testing the

ducts in all the NEEM homes they produce, which is expected

to result in even tighter duct systems. Field testing of

a sub-sample of these homes duct testing began in 2004

and continues. This field testing is also evaluating homes

that employed a “thru-rim” crossover duct system.

BAIHP staff continues to work with EPA and other regional

partners on clarifying the equivalency of SGC with ENERGY

STAR. In 2002, BAIHP staff developed a new ENERGY STAR compliance

path for climate zone 2 that does not require a heat pump.

The non-heat pump path uses a heat recovery ventilation system,

a .93 EF hot water heater and tighter ducts and envelope.

This path was not utilized due to reluctance by manufacturers

to install HRV systems. In 2004, this path was modified to

eliminate the HRV, and include options such as set-back T-stats,

ENERGY STAR dishwasher, adjusted glazing limits, improved

window U-factors, and in-plant tested duct systems.

Revised In-plant Manual

In 2003, in light of the revisions to the NEEM specifications,

BAIHP staff from the Oregon Department of Energy developed

an updated in-plant inspection manual, with new graphics,

including details on correct installation of heat recovery

ventilation. Many of the manual updates are the result of

BAIHP research and demonstration efforts, including use of

hybrid floor systems and proper duct sealing with mastic.

The manual also now includes a regionally consistent problem

home inspection protocol.

In-plant QC Training

In 2004, BAIHP staff from the Oregon Department of Energy

developed a PowerPoint presentation, based on the revised

In-plant manual. In 2004, BAIHP staff began using this presentation

to train QA staff at each plant; this effort will continue

until all NEEM plants have received this training.

In-Plant Inspections

On

a quarterly basis, BAIHP staff visits each of the manufactured

housing plants to verify compliance with SGC/E-Star specifications.

Inspections include a plant audit, ventilation system testing,

and troubleshooting construction-related problems with plant

staff and independent inspectors. Consistent issues in the

plant include wall insulation compression or voids due to

improper cutting of batts, attention to duct installation

and air sealing. Specific in-plant inspection reports conducted

in Washington in program Year 6 (March 2004 – April

2005) are provided to FSEC.

Transition to mastic

As

mentioned above, the NEEM program eliminated the use of

butyl tape for duct sealing, and required the use of mastic.

As of spring 2004, ten manufacturers have successfully

transitioned to mastic. Testing in-plant has indicated

significant improvement in duct leakage rates of homes

in these factories– an

average 36.8 cfm @ 25 PA (versus 50.1 cfm @ 25 PA pre-mastic),

a 27% improvement. This trend continued into 2005.

WSU and ODOE began working with Fleetwood engineers to

evaluate a new lower cost duct leakage testing device that

Fleetwood is considering using in all of its plants throughout

the USA. The preliminary results suggested a need utilize

10 second averaging and set a higher pressure ratio from

86% to 90% to be consistent with NEEM duct leakage targets.

This work will continue through program Year 7.

Duct Workshops

Through the spring of 2005, BAIHP staff continued to provide

workshops focused on improved duct installation and inspection

oversight, working in partnership with BAIHP partners. One

in-plant duct leakage workshop resulted in the identification

of significant duct leakage (branch disconnect) which re-enforced

the need to consider duct testing of all units at that plant. New Technology Evaluations

High

Efficiency Gas Furnaces

|

Figure

33 90% AFUE

Furnace, as installed at Kokanee Creek |

Initial

evaluations of 90% efficient gas furnaces indicates that

there is no incremental installation cost to the use

of these furnaces, as no field modifications are required.

In 2003, Nordyne and Evcon came out with furnaces with

an appropriate footprint for manufactured housing; Intertherm

also continues to offer a 90% efficient model. Discussion

with BAIHP home manufacturer partners Fuqua, Marlette,

Champion, and Fleetwood, and furnace manufacturer partners

Evcon and Nordyne, indicate the that this market is growing

quickly, especially in homes with high pitch “tilt-up” roof

systems, and multi-story homes such as at Nogi Gardens

and Kokanee Creek. The ability to use wall venting instead

of roof venting with condensing furnaces makes them more

attractive where tilt-up roofs are employed.

Through the rim crossover duct system

Three

Oregon manufacturers, Marlette, Skyline and Homebuilders

Northwest, adopted a crossover duct system that runs through

a cut out section of the rim joist, effectively placing

the entire crossover system in the heated space. A gasket

on the marriage line provides a seal between sections.

Challenges with the use of this system include the need

for very accurate measurements to insure matching of the

duct connection, and careful treatment of the gasket material

during set up, so that it doesn’t detach from the

rim.

Evaluations suggest that that further improvement to

gasket systems may be needed to ensure set-up that achieves

effective duct sealing.

La Salle Duct Riser

BAIHP

staff worked with BAIHP partner La Salle Air to design

and produce a duct riser for manufactured homes that

uses mastic instead of tape. BAIHP staff demonstrated

prototype designs of the riser to Northwest manufacturers

in Year 3. Most NEEM manufacturers adopted the new risers

or equivalent systems in year 6. . BAIHP staff worked with

Fleetwood’s national office to promote the use of

the riser in all Fleetwood plants. During 2003-2004, BAIHP

staff promoted the use of this technology at the annual

MHI conferences and energy road-mapping meetings.

Flexible Technologies:

BAIHP

partner Flexible Technologies has developed innovative

systems that improves the heat and tear resistance of the

duct inner liner, reduces the crimping of ductwork without

the use of sheet metal elbows, and an improved system to

air seal where the crossover duct penetrates the bottom

board. BAIHP staff evaluating the use of this system in

the WSU Energy House and ZEMH, and worked with Flexible

Technologies staff to promote the use of the new system

to the region’s manufacturers. Efforts to gain market

adoption of the technology remain challenging due to first

cost increases and lack of demonstrated benefits.

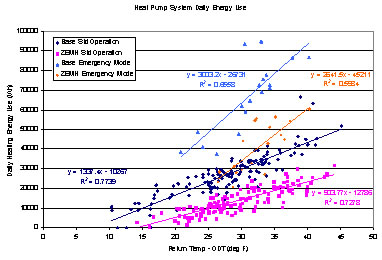

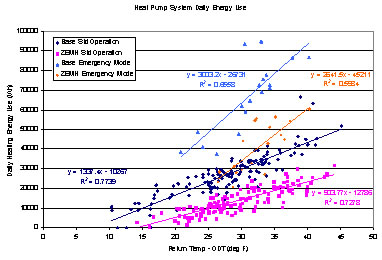

Figure 34 Insider Heat Pump

in ZEMH and Base Home –

Operation in HP and Strip

Heat Mode

Insider Heat Pump

Monitoring of the Insider heat pump at the WSU Energy

House was begun in 1999. Measured flow rate of the indoor

unit was good (850 CFM total, 425 CFM per ton), but BAIHP

staff identified two performance issues: a too-frequent

operation of the defrost cycle and a lower than expected

airflow at the outdoor coil. Continued testing of the Insider

in 2002 indicated a 10% increase in COP due to increased

airflow at the outdoor coil. At Vincent Village, the property

manager indicated a high degree of satisfaction with the

Insider heat pumps, with no comfort complaints. Flip flop

testing that varies the compressor and electric resistance

heat were conducted in the WSU and ZEMH. The results of

those tests being analyzed for a ASHRAE paper to be submitted

in 2005. The Insider Flip flop test results are presented

in Figure 34.

Energy Conservatory

BAIHP staff work with the Energy Conservancy (EC) to

evaluate their new products for measuring air handler and

exhaust fan flows. In 2004, BAIHP staff worked with EC

staff to develop an automated test that will provide duct

leakage to outside. Discussion with EC indicated significantly

increased sales of duct blasters to HUD-code manufacturers

as a result of BAIHP efforts. WSU continues to work with

EC to develop new building science tools for HUD-code housing.

Other Technologies

In 2004, BAIHP staff submitted a status report summarizing

program efforts to introduce BAIHP manufacturers to new

technologies. The report highlights the barriers and successes

made regarding:

- 24” OC

Wall Framing

- Air-Tight Can Lighting

Fixtures

- Solar Ready design

- Improved flashing/drainage systems

- High Efficiency

Water Heaters

- Blown Cellulose Hybrid Floor Insulation

- Condensing

Gas Furnaces

- Heat

Pump Water Heaters – Site built

- Hi-R

wall Systems (Foam Sheathing + Icynene) – Site

Built

Research Support

ASHRAE

During

2003, in the capacity of chairing ASHRAE’s

6.2 Technical committee, BAIHP staff directed a major effort

to revise Chapter 9 of the ASHRAE Systems Handbook, “Design

of Small Forced-air Heating and Cooling Systems.” The

revisions to the chapter, which incorporated BAIHP research,

were accepted by the committee, and forwarded to ASHRAE

for publication. In 2004 BAIHP staff provided assistance

to other BA teams to improve chapter 43 of the ASHRAE Applications

Handbook – Envelopes.

BAIHP staff have also participated in ASHRAE research

projects, conferences, symposiums, seminars and forums,

including:

- Authoring a paper on duct leakage, which was submitted

and approved for presentation at ASHRAE summer meeting

in 2004.

- Making

a presentation at the ASHRAE summer meeting in 2003, “Uncontrolled

Air Flow in Small Commercial Buildings.”

- Moderating

a forum on HVAC experiences in HUD code housing at

ASHRAE’s summer meeting in 2002. 20

industry and building science professionals participated

in the forum.

- Co-chairing

ASHRAE’s Technical Committee 6.3 – Residential

Forced Air Heating and Cooling Equipment, which is responsible

for ASHRAE standard 152 – Thermal Distribution

Systems.

- Building America research on ductwork and HVAC systems

will be included in the next version of the ASHRAE standards.

Building America research will also be a part of future

efforts in TC 6.3.

NFPA-501

BAIHP continues to support the NFPA standards process.

The NFPA standard is typically incorporated into the HUD

code, which governs the construction of over 250,000 HUD

code homes each year.

- In 2003, BAIHP staff integrated BAIHP duct leakage

and cost data into proposals to the NFPA-501 committee.

Based on this data, NFPA approved a new standard on duct

tightness, as well as a refined duct testing protocol.

- In 2002, BAIHP staff cited Building America research

and demonstration efforts in support of additional successful

proposals for standards revision, including duct testing,

and use of mastic in duct sealing.

ACEEE

- BAIHP

staff have co-authored two papers presented at ACEEE

Conferences, “Pushing the Envelope: A

Case Study of Building the First Manufactured Home Using

Structural Insulated Panels,” and “Washington

State Residential Ventilation and Indoor Air Quality

Code (VIAQ) - Whole House Ventilation Systems Field Research

Report.”

- In 2004, BAIHP staff coordinated 24 peer reviewed

papers for the Residential technologies track at the

Summer Study and coordinated informal sessions on HUD-code

housing.

National Institute of Standards and Technologies

(NIST)

BAIHP staff continues to work with NIST staff and industry

representatives to evaluate ventilation and IAQ issues

in HUD code homes.

- BAIHP staff also worked with NIST and the Energy Conservancy

to perform tests on a typical HUD code model house on

the NIST campus in Gaithersburg, Maryland. Testing indicates

low flow rates of the whole house ventilation system

and significant duct leakage.

- In 2004, discussions with NIST, LBL, Ecotope and Energy

Conservatory continued on a retrofit research effort

with Dupont Tyvek, and development of new ventilation

system controls with Panasonic. These discussions will

continue.

National Manufactured Housing Research Alliance (MHRA)

BAIHP

staff continues to participate on MHRA’s

ENERGY STAR committee, which is developing Quality Assurance

procedures with USEPA on ENERGY STAR manufactured homes.

An article on the ZEMH appeared in the MHRA newsletter.

WSU worked with MHRA to provide an article on the ZEMH

project. WSU continues to provide technical support to

MHRA on ENERGY STAR and other building science/energy related

efforts such as the MHI roadmap.

|

You

are here: >

You

are here: >