|

Appendix

C: 2005 Annual Report

of Washington State University Energy Program (WSU) with

Oregon Office of Energy, and Idaho Department of Water

Resources, Energy Division

Annual Report

BUILDING AMERICA INDUSTRIALIZED HOUSING

PARTNERSHIP

WSU Extension Energy Program, IDWR,

ODOE

April 1, 2004 – March 30, 2005

The Washington State University Energy Program (WSU), together

with partners Oregon Office of Energy and Idaho Department

of Water Resources, Energy Division, continue to provide

technical and research support to the Northwest Energy Efficient

Manufactured Housing Program (NEEM program in the Pacific

Northwest. The NEEM program involves 20 plants in three states,

hundreds of retailers and thousands of homebuyers.

The NEEM program includes the brands Super Good Cents and

ENERGY STAR, and includes homes heated by electricity and

Natural Gas/propane. Prior to Year 5, the NEEM program also

included the Natural Choice brand, which was exclusive to

homes heated with Natural Gas or propane. In Year 5, the

Natural Choice brand was phased out; now, all gas heated

homes are branded ENERGY STAR. In Year 6, a new path for

ENERGY STAR was developed for Super Good Cents homes with

electric furnaces. Homes will be built to this path beginning

in year 7.

In Year 6, NEEM staff began to provide technical assistance

to Champion Homes on a 700 unit private military modular

housing development at Ft. Lewis. In-plant verification,

certification and on-site verification of these homes began

in year 6 and will continue in year 7 as a major BAIHP effort.

In Year 6, technical assistance by NEEM staff to the Energy

Trust of Oregon resulted in the development of a million

dollar utility incentive program that promotes the production

of a more NEEM homes built to higher benchmarking levels

consistent with BAIHP goals. A technical analysis of the

ETO program has been provided to FSEC.

Between years 1-6, WSU staff provided technical assistance

and guidance to the NAHB Research Center Energy Value Housing

Awards, judging submittals, providing de-briefing to builders,

and participating on workshops. NEEM builders Fleetwood,

Champion, Valley and Marlette have received EVHAs for factory

built housing.

Aligning with New Building America Goal

During Year 6, BAIHP staff performed a benchmarking evaluation,

(included in the Year 5 annual report) to assess the improvement

of NEEM homes over the entire BAIHP project period. The benchmarking

was based on a home defined by NREL (built to IECC requirements).

The savings over the benchmark home were estimated using

version 2.2 of Energy Gauge USA. Evaluations were performed

for a typical 1600 ft 2 double wide home with 12% glazing

to floor area (the NEEM fleet average) in three Pacific Northwest

climate zones: Portland, OR; Spokane, WA; and Missoula MT.

The homes were benchmarked assuming a continuously operating

whole house ventilation system, resulting in a significant

thermal energy penalty. Additional benchmarking was also

conducted using the 164 kWh/year ventilation assumption in

the NREL benchmark, in an effort not to penalize the homes

for improved IAQ associated with HUD whole house ventilation

system requirements and ASHRAE 62.2.

In Years 5 and 6, improvements were made to NEEM HVAC systems

and duct specifications as a result of BAIHP research (see

Refinement of NEEM Specifications, below.) Additional benchmarking

is presented that reflects these improvements.

The results of the benchmarking vary considerably by HVAC

type, water heat and climate, as noted in Table C1 below.

Some key observations:

- In all climate zones, electric homes result in negative

savings if the ventilation penalty is assumed. This is

largely the result of the assumption that the benchmark

home has a heat pump that performs without installation

problems; an assumption that will be evaluated by BAIHP

research.

- Gas heated NEEM homes came closest to meeting the overall

BAIHP goal of 40% over the NREL benchmark, but only met

the goal if gas heat is paired with electric water heat,

in cold climates with no ventilation system penalty.

- Eliminating the ventilation system penalty has a higher

impact on benchmarking results (9 to 23 percentage points)

than improved duct leakage tightness (3 to 11 percentage

points).

- It should be noted that Benchmarking these NEEM homes

against the HUD-FMCSS requirements (Uo=.079) for manufactured

homes rather than the IECC (Uo=0.06) would yield considerably

higher savings than current benchmark assumptions.

Table

C1 Benchmarking Savings Results |

Duct Leakage |

Pre-2004* |

2004** |

Pre-2004* |

2004** |

Ventilation System Penalty |

Yes |

Yes |

No |

No |

Portland |

Electric Furnace |

-31 |

-20 |

-8 |

0 |

Heat Pump |

11 |

14 |

20 |

22 |

Gas Heat/Elec DHW |

16 |

22 |

32 |

37 |

Gas Heat/Gas DHW |

15 |

20 |

30 |

34 |

Spokane |

Electric Furnace |

-18 |

-9 |

2 |

10 |

Heat Pump |

17 |

21 |

27 |

30 |

Gas Heat/Elec DHW |

22 |

27 |

36 |

41 |

Gas Heat/Gas DHW |

21 |

26 |

35 |

39 |

Missoula |

Electric Furnace |

-12 |

-3 |

8 |

15 |

Heat Pump |

17 |

22 |

28 |

32 |

Gas Heat/Elec DHW |

21 |

26 |

35 |

40 |

Gas Heat/Gas DHW |

20 |

25 |

34 |

38 |

*

Pre-2004 – Duct

leakage of -132 cfm@25PA

** 2004 – Duct

leakage of -60 cfm@25PA

|

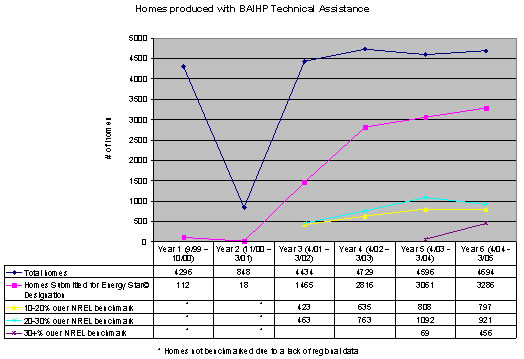

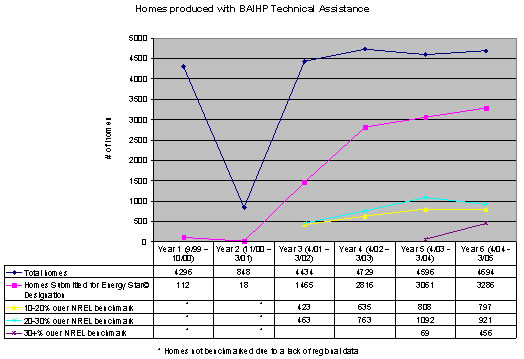

Technical Assistance/ Figure C1 shows,

by program year, the number of homes produced with technical

assistance from BAIHP, as well as the number of homes submitted

for ENERGY STAR designation by BAIHP staff and the breakdown

of homes by benchmarking score. Please note the following:

- The benchmarking includes the assumption, based on the

random study (see Random Study, below) that

24% of all homes included after-market heat pumps.

- No benchmarking was performed for Years 1 and 2, due

to a lack of accurate regional data.

- In Years 5 and 6, the appearance of homes that achieved

a 30+% benchmark is the result of the improvements made

to the NEEM HVAC specifications.

- Figure C1 averages benchmarks for Spokane and Missoula

for homes in cold climates and uses the Portland benchmark

for marine climates. Figure C1 also assumes an average

value between ventilation penalty and no ventilation penalty.

Figure C1

The continued success of the program is due to several

factors. BAIHP and NEEM staff worked to increase awareness

within the manufactured housing industry of the marketing

value of energy efficiency, increase participation by utilities

in incentive programs, and promote the co-branding of NEEM

with ENERGY STAR.

The

increase in ENERGY STAR designations is due to refinement

of the SGC duct sealing specifications, resolving a discrepancy

between the SGC specifications with ENERGY STAR’s

duct sealing protocols (while this question was being resolved

[Years 1-2], BAIHP staff did not submit homes to DOE for

ENERGY STAR designation). In year 5, remaining discrepancies

with manufacturers in Idaho were further resolved, allowing

BAIHP staff to accurately report all qualifying homes.

SGC/E-STAR program activities include:

Refinement of SGC specifications: BAIHP staff

continually work to refine the existing SGC specifications,

a result in large part to innovative building technologies

researched in BAIHP.

In Year 5, BAIHP staff worked with NEEM staff and manufacturers

to develop revisions to NEEM specifications, including allowing

only mastic for duct sealing, requiring metal flex duct for

whole house ventilation fans, and changing the air infiltration

specification from 7.0 ACH 50 to 5.0 ACH 50.

The revised specifications were voted on and accepted by

the manufacturers; they took effect on January 1, 2004.

In

year 6 5 in Oregon, 1 in Idaho plants began testing the

ducts in all the NEEM homes they produce, which is expected

to result in even tighter duct systems. Field testing of

a sub-sample of these homes duct testing began in year

6 and continues in year 7. This field testing is also evaluating

homes that employed a “thru-rim” crossover

duct system.

BAIHP staff continues to work with EPA and other regional

partners on clarifying the equivalency of SGC with ENERGY

STAR. In Year 4, BAIHP staff developed a new ENERGY STAR

compliance path for climate zone 2 that does not require

a heat pump. The non-heat pump path uses a heat recovery

ventilation system, a .93 EF hot water heater and tighter

ducts and envelope. This path was not utilized due to reluctance

by manufacturers to install HRV systems. In year 6, this

path was modified to eliminate the HRV, and include options

such as set-back T-stats, ENERGY STAR dishwasher, adjusted

glazing limits, improved window U-factors, and in-plant tested

duct systems.

Revised In-plant Manual: In Year 5, in light

of the revisions to the NEEM specifications, BAIHP staff

from the Oregon Department of Energy developed an updated

in-plant inspection manual, with new graphics, including

details on correct installation of heat recovery ventilation.

Many of the manual updates are the result of BAIHP research

and demonstration efforts, including use of hybrid floor

systems and proper duct sealing with mastic. The manual also

now includes a regionally consistent problem home inspection

protocol.

In-plant QC Training: In year 6, BAIHP staff from

the Oregon Department of Energy developed a PowerPoint presentation,

based on the revised In-plant manual. In year 6, BAIHP staff

began using this presentation to train QA staff at each plant;

this effort will continue in year 7, until all NEEM plants

have received this training.

SGC Random Home Testing: In 1994-1995 (prior

to implementation of BAIHP), SGC staff conducted field testing

of 178 SGC homes built in 1992-1993. In BAIHP Year 1, staff

in Idaho and Washington field-tested 49 SGC homes built in

1997-98. In Year 2, analysis of field test data confirmed

some improvements to home set-up procedures and air leakage

control, while highlighting a need to improve duct tightness

and ventilation system operation (through homeowner education.)

In Year 3, BAIHP staff produced an updated homeowner ventilation

brochure.

In Years 4 and 5, BAIHP staff worked with Ecotope to develop

a valid sample for the next round of field testing, and began

to develop the field testing protocol. In year 5, Ecotope

selected 105 homes from the total production for the years

2001-2002. The field testing took place in the summer of

Year 5. Findings from the testing include:

- Average house size is 1769 ft 2; double section homes

are also getting bigger, on average. The house size is

very comparable to the homes built in 1997-1998 but 20%

larger than the homes in 1994-1995 study

- Houses are getting tighter, according to the blower

door results. The average air leakage rate at 50 Pa is

4.2, which represents a tightening of almost 25% over the

original MAP home average. The median equivalent leakage

area (ELA) for double-section homes has decreased by about

12% despite a substantial increase in house size.

- Only about 20% of NEEM homes in this study contain intentional

outside air inlets. This is the result of BAIHP research

indicating that intentional outside air inlets are unnecessary

to provide adequate fresh air.

- 2/3 of homes in the study have dedicated whole house

fans and a substantial fraction of homeowners are using

their whole house fans. However, a significant minority

(30%) does not turn them on.

- About half of homes in the study use central cooling,

with more than half of these homes using a heat pump.

- Duct systems are about 20% leakier than in the Year

1 study and about 10% leakier than in the 1994-1995 study

(when the comparison is normalized by house size).

- The median supply leakage fraction is 11-13% for the

homes in this sample. The duct loss translates into a heating

system efficiency loss of between 10-20% overall, depending

on the location of the home (west side or east side of

the mountains) and type of heating equipment (heat pumps

perform worse).

In year 6, BAIHP staff conducted a billing analysis on

a limited number of random field study homes. The conclusions

(although not statistically significant) suggest that temperature

related energy use in NEEM homes remains similar to previous

larger studies on cost-effectiveness. The analysis attempted

to evaluate total and space conditioning energy use by HVAC

system types but was limited by small sample size.

In

year 6, a sub-sample of homes that are believed to represent

the best case for duct tightness were selected for additional

field testing. These homes include those with in-plant

tested ducts and thru-rim crossover duct systems. The goal

of this effort is to establish a “tightest” duct

case benchmark. Field testing will be completed in year

7; report will follow.

Problem Homes: In offering technical support

to owners of over 100,000 homes built since 1990, the staff

answers questions from homeowners, manufacturers, retailers

and others. In Year 6, staff from Washington, Oregon and

Idaho responded to over 25 phone calls and conducted 10(OR)

field visits.

The

number of problem home field visits has significantly decreased

over the history of the program, in large part because

of manufacturer’s and installer’s

increased awareness of the SGC/E-Star specifications, and

the requirement that manufactured home installers be certified

in Washington and Oregon. Efforts were made in year 6 to

improve regional coordination of problem home tracking

and reporting.

BAIHP staff began to utilize Energy Gauge USA as a tool

for evaluating high bill complaints in year 6. Specific problem

home reports conducted in Washington in year 6 are provided

to FSEC. Reports for the other states are available from

ID, MT and OR State Energy Offices.

BAIHP staff participated in quarterly meetings of the Washington

State Manufactured Housing Technical Working Group, which

coordinates the certification of manufactured housing set-up

crews.

While butyl duct tape is no longer allowed under current

NEEM specifications, a consistent issue in the field continues

to be excessive duct leakage, due in large part to failures

of duct tape. These findings were brought to the attention

of the NFPA-501 Mfg Housing Standards committee, resulting

in a successful proposal to revise the duct sealing specifications

in the NFPA-501 standard in year 5.

In year 6, further improvements to NFPA-501 were made that

focused a variety of energy related improvements, with the

potential of increasing consumer comfort and lowering energy

bills; high among these was improved procedures involving

in-plant testing of ducts.

In-Plant Inspections: On a quarterly basis, BAIHP

staff visits each of the manufactured housing plants to verify

compliance with SGC/E-Star specifications. Inspections include

a plant audit, ventilation system testing, and troubleshooting

construction-related problems with plant staff and independent

inspectors. Consistent issues in the plant include wall insulation

compression or voids due to improper cutting of batts, attention

to duct installation and air sealing. Specific in-plant inspection

reports conducted in Washington in year 6 are provided to

FSEC.

Transition to mastic: As

mentioned above, the NEEM program eliminated the use of

butyl tape for duct sealing, and required the use of mastic.

As of the end of Year 5, ten manufacturers have successfully

transitioned to mastic. Testing in-plant has indicated

significant improvement in duct leakage rates of homes

in these factories– an

average 36.8 cfm @ 25 PA (versus 50.1 cfm @ 25 PA pre-mastic),

a 27% improvement. This trend continued in year 6.

WSU and ODOE began working with Fleetwood engineers to

evaluate a new lower cost duct leakage testing device that

Fleetwood is considering using in all of its plants throughout

the USA. The preliminary results suggested a need utilize

10 second averaging and set a higher pressure ratio from

86% to 90% to be consistent with NEEM duct leakage targets.

This work continues in year 7.

Duct Workshops: In Year 6, BAIHP staff continued

to provide workshops focused on improved duct installation

and inspection oversight, working in partnership with BAIHP

partners. One in-plant duct leakage workshop in year 6 resulted

in the identification of significant duct leakage (branch

disconnect) which re-enforced the need to consider duct testing

of all units at that plant.

Demonstration Homes: In Year 6, technical support

was provided for the following demonstration homes:

-Zero Energy Manufactured Home (ZEMH): BPA,

working with BAIHP staff in Idaho and Washington,

provided funding for the most energy efficient manufactured

home in the country. The RFP was sent to 18 Northwest manufacturers;

Kit Homes of Idaho was selected as the manufacturer

of the home. BAIHP staff solicited 24 industry partners

to provide energy efficient building components, including

Icynene wall, floor and roof insulation, a low-cost

HUD-approved solar system, sun-tempered solar design, and

ENERGY STAR© windows,

appliances and lighting. Partners include Building

America Team members such as Flexible Technologies, Icynene

and LaSalle.

Figure 2 Zero Energy Manufactured

Home,

on site at the Nez Perce Fish Hatchery

The ZEMH was built in Year 4 along with a control home.

The ZEMH was displayed at the 2002 Spokane County Interstate

Fair before siting at the Nez Perce tribal fish facility

near Lewiston Idaho. Blower door and duct leakage tests at

the plant and on-site indicate that this is the tightest

home ever tested by BAIHP staff.

Working with FSEC and BPA, BAIHP staff installed monitoring equipment for the

ZEMH. Monitoring of the home began in Year 5 and continued in year 6 and 7.

Preliminary findings include:

- Measured

net energy use of the ZEMH 6% is lower than the base

home, not normalized for occupant behavior. This also

does not take into account the fact that the ZEMH’s

PV system was only fully operational for one month.

- The ZEMH required 45% less space heating energy, possibly

due to improved building envelope measures, and the lack

of consistent HRV operation.

- The measured envelope leakage in the ZEMH was 2.0 ACH

50, much lower than the base home (indeed, lower than any

other NEEM home tested in the field) and substantially

tighter than typical HUD code homes.

- The ZEMH total duct leakage was 46% lower than the base

home; leakage to the outside was 405% lower than the base

home. BAIHP staff speculate that the unprecedented low

leakage to the outside value is the result of the ducts

in the ZEMH being located within the conditioned space,

and effectively within the pressure envelope of the home,

surrounded as they are by foam insulation.

- The solar water heating system in the ZEMH provides

most, if not all of the energy needed during the summer

months, and roughly 45% of the overall water heating energy

use.

- The PV system with net metering provides 38% of the

total ZEMH energy use.

The

project highlights the importance of occupant choices and

behavior on the performance of energy efficient housing.

Based on the preliminary monitoring data and occupant surveys,

the behavior patterns of the ZEMH occupants are not themselves “energy

efficient”. These patterns create the appearance of

a less efficient home. On the other hand, the behavior of

the ZEMH occupants may shorten the payback for the innovative

technologies of the ZEMH.

BAIHP staff also performed a benchmarking analysis on the

ZEMH, as part of the overall benchmarking effort. The ZEMH

reached a level of 60% above the NREL prototype, which indicates

the difficulty of obtaining a high benchmarking score . In

year 6 a research paper was presented at BTECC which provided

a preliminary evaluation of the ZEMH performance without

the full operation of the PV net metering system. By the

end of year 7 there will be a full year of ZEMH data, with

the PV system operational.

NOGI Gardens:,

Nogi Gardens is a 75-home community located in southeast

Seattle The project contains the first two-story, HUD code

attached “townhouse homes.” All

the homes have been built by Marlette Homes in Hermiston,

Oregon to SGC/E-Star specifications. A blower door test

of the building envelope showed 5.0 ACH at 50PA, average

for a manufactured home in the Pacific Northwest. Duct

leakage is very low, due to Marlette’s use of mastic

and duct risers. During Year 5, Nogi Gardens was the recipient

of the HUD Secretary’s Gold Award for Excellence.

Marlette was also the winner of the Energy Value Housing

Award in Year 5.

|

Figure

3 Kokanee Creek

HUD-code

Multi-Story HID-code housing |

Kokanee Creek: In year 6 Marlette was involved

with a new 32 home multi-story development called Kokanee

Creek. BAIHP staff conducted field evaluation on the first

set of homes and provided technical assistance to Marlette

and the developer HomeSight, related to the envelope and

duct leakage improvements.

WSU Energy House: This 2600 ft. 2 home has been

built to beyond SGC standards, and incorporates ENERGY STAR

lighting and appliances. The home has received significant

national exposure through tours, local and trade media, and

the BAIHP website, which includes house monitoring data.

BAIHP staff use the house to test additional innovative technologies

and testing methods. In Year 5, BAIHP staff developed a moisture

case study based on research at the WSU Energy House, published

under a separate Building America project. In year 6, moisture

problems associated with siding and trim details were eliminated

using and an improved window flashing system. The adoption

of this system is currently under discussion with some manufacturers,

and NFPA-501.

Habitat for Humanity : In year 6, WSU staff began

providing technical support to BAIHP partner Habitat for

Humanity. Support was provided , specifically for two site

built projects in Olympia, WA (marine climate) and Grant

Co. (cold climate). Technical support on was included; HVAC

design, Energy Gauge analysis and field testing assistance.

WSU continues to evaluate these homes year 7, when final

case studies will be completed.

The Olympia home highlighted the challenges of integrating “green” technologies;

such as Icynene insulation, and Rastra block walls. The home also used instant

flow gas combo hydronic HVAC and HRV systems, and energy star lighting, appliances

and was built “solar ready”.

The Grant country home utilized standard construction materials and framing,

ENERGY STAR HVAC, lighting and appliances. This home moved 100% of the duct

system into the conditioned space; from the attic, crawlspace and garage where

it was to be installed, at little or no additional cost.

In addition to the projects listed above, previous highlights

from BAIHP research include:

- Vincent Village: Vincent Village is a 49 home

rental community, located in Richland, WA. All of the homes

are small, single section, heated and cooled by Insider heat

pumps. Half the homes were built to SGC standards, the other

half were not. Metered utility data indicate average yearly

savings of $241 for the SGC homes.

- Fish Facility: Three SGC homes were built at

the Nez Perce tribal fish facility in Cle Elum, Washington.

One of these homes is equipped with ENERGY STAR appliances

and lighting; all three homes are heated with Insider heat

pumps. Testing revealed significant envelope and duct leakage,

likely due from failure of butyl duct tape at risers.

- SIP House: This home, located in Western Washington

and constructed by Champion Homes, is the first stress skin

insulated panel manufactured home. House tightness was measured

at 3.55 ACH at 50 Pa, well below the average numbers for

all previous random home studies. Energy savings are estimated

at 50% greater than HUD code minimum.

Field Monitoring: In Year 5, monitoring equipment

was installed in the ZEMH and base home. The monitoring

equipment collects the following energy use data from each

home:

- Total electric use from grid

- Resistance elements in heat pump

- Heat pump compressor and fan motors

- Water heating equipment, including gallons used

- PV energy production (ZEMH)

Sensor data are collected

every 15 minutes by data loggers and transmitted daily

to the host computer. Summary data reports are available

at: http://infomonitors.com/zmh/.

Plug-type energy loggers were installed in mid March

2003 to sub-meter the energy use of the refrigerator,

freezer and clothes washer in each home, as well

as the radiant heat panel and HRV in the ZEMH. Data

from these loggers was collected (by occupant readings)

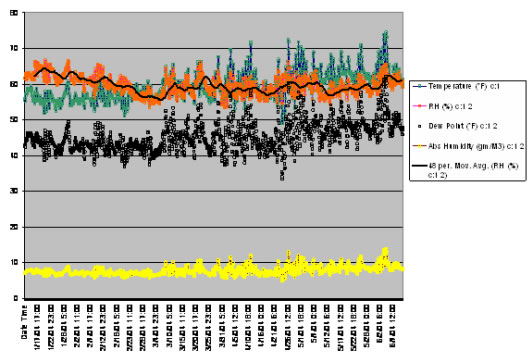

in mid-December 2003. The WSU Energy House data has been monitored since year

1. Monitoring data being collected includes weather, temperature,

humidity, CO 2, CO, and 8 differential pressures. Energy

use data from water heat, laundry, fireplace, and HVAC

are also being collected. Monitoring results from the WSU

Energy House have been presented to the building science,

IAQ and HVAC research communities at ASHRAE, AIVC, HUD/NIST,

NFPA and BETEC. Data is available at http://logger.fsec.ucf.edu/cgi‑bin/wg40.exe?user=lubresidence

New Product and Technology Evaluation

Blown Cellulose Floor Insulation: Industry partner

Greenstone has been working with BAIHP staff and SGC/E-STAR

manufacturers to evaluate a hybrid floor insulation system.

These systems, composed of one R-11 belly blanket and

R-22 blown cellulose insulation eliminates over-compression

and reduces the chance of leakage during transport and

set-up, while minimizing material and labor costs. Fleetwood

Homes of Washington adopted this system for all of their

homes in Year 3. Other manufacturers have adopted the

hybrid floor insulations system, which provides less

insulation voids and reduces first cost of R33 floor

system over 3-R11 fiberglass batts. One potential consequence

of using the hybrid system is increased moisture in the

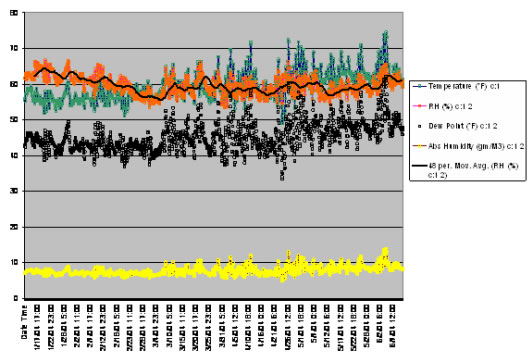

belly; in Year 5, BAIHP staff installed data loggers

in two homes to determine whether this is a problem;

after the data loggers were retrieved in Year 6, BAIHP

staff submitted a report to Fleetwood suggesting no dew

point problems within the floor system, as shown in Figure

C4.

Figure C4 Temperature and

Dew Point Under Hybrid Floor Decking

High Efficiency Gas Furnaces: Initial

evaluations of 90% efficient gas furnaces indicates that

there is no incremental installation cost to the use

of these furnaces, as no field modifications are required.

In Year 5, Nordyne and Evcon came out with furnaces with

an appropriate footprint for manufactured housing; Intertherm

also continues to offer a 90% efficient model. Discussion

with BAIHP home manufacturer partners Fuqua, Marlette,

Champion, and Fleetwood, and furnace manufacturer partners

Evcon and Nordyne, indicate the that this market is growing

quickly, especially in homes with high pitch “tilt-up” roof

systems, and multi-story homes such as at Nogi Gardens

and Kokanee Creek. The ability to use wall venting instead

of roof venting with condensing furnaces makes them more

attractive where tilt-up roofs are employed.

Figure C5 90% AFUE Furnace,

as installed at Kokanee Creek

- Through the rim crossover duct system: Three

Oregon manufacturers, Marlette, Skyline and Homebuilders

Northwest, adopted a crossover duct system that runs

through a cut out section of the rim joist, effectively placing

the entire crossover system in the heated space. A gasket

on the marriage line provides a seal between sections.

Challenges with the use of this system include the need

for very accurate measurements to insure matching of

the duct connection, and careful treatment of the gasket

material during set up, so that it doesn’t detach from

the rim.

Year 6 evaluations suggest that that further improvement

to gasket systems may be needed to ensure set-up that achieves

effective duct sealing.

- La Salle Duct Riser: BAIHP

staff worked with BAIHP partner La Salle Air to design

and produce a duct riser for manufactured homes that

uses mastic instead of tape. BAIHP staff demonstrated

prototype designs of the riser to Northwest manufacturers

in Year 3. Most NEEM manufacturers adopted the new risers

or equivalent systems in year 6. . BAIHP staff worked

with Fleetwood’s national office

to promote the use of the riser in all Fleetwood plants.

During Years 5 and 6, BAIHP staff promoted the use of this

technology at the annual MHI conferences and energy road-mapping

meetings.

- Flexible Technologies: BAIHP

partner Flexible Technologies has developed innovative

systems that improves the heat and tear resistance of

the duct inner liner, reduces the crimping of ductwork

without the use of sheet metal elbows, and an improved

system to air seal where the crossover duct penetrates

the bottom board. BAIHP staff evaluating the use of this

system in the WSU Energy House and ZEMH, and worked with

Flexible Technologies staff to promote the use of the

new system to the region’s manufacturers.

Efforts to gain market adoption of the technology remain

challenging due to first cost increases and lack of demonstrated

benefits.

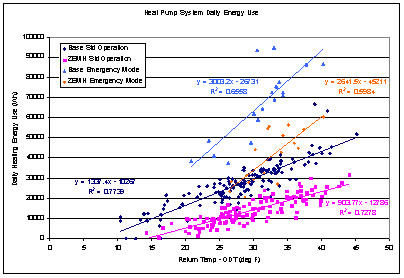

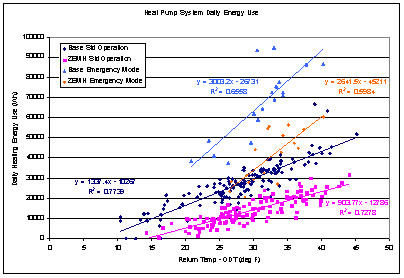

- Insider Heat Pump: Monitoring of the Insider

heat pump at the WSU Energy House was begun in Year 1.

Measured flow rate of the indoor unit was good (850 CFM

total, 425 CFM per ton), but BAIHP staff identified two

performance issues: a too-frequent operation of the defrost

cycle and a lower than expected airflow at the outdoor

coil. Continued testing of the Insider in Year 3 indicated

a 10% increase in COP due to increased airflow at the outdoor

coil. At Vincent Village, the property manager indicated

a high degree of satisfaction with the Insider heat pumps,

with no comfort complaints. Flip flop testing that varies

the compressor and electric resistance heat were conducted

in the WSU and ZEMH. The results of those tests being analyzed

for a ASHRAE paper to be submitted in year 7. The Insider

Flip flop test results are presented in Figure C6.

Figure C6 Insider Heat

Pump in ZEMH and Base Home

- Operation in HP and Strip

Heat Modes

- Energy Conservatory: BAIHP staff work with

the Energy Conservancy (EC) to evaluate their new products

for measuring air handler and exhaust fan flows. In Year

6, BAIHP staff worked with EC staff to develop an automated

test that will provide duct leakage to outside. Discussion

with EC indicated significantly increased sales of duct

blasters to HUD-code manufacturers as a result of BAIHP

efforts. WSU continues to work with EC to develop new building

science tools for HUD-code housing.

Other New Technologies: In year 6, BAIHP staff

submitted a status report summarizing program efforts to

introduce BAIHP manufacturers to new technologies. The

report highlights the barriers and successes made regarding:

- 24” OC

Wall Framing

- Air-Tight Can Lighting Fixtures

- Solar Ready design

- Improved flashing/drainage systems

- High Efficiency Water Heaters

- Blown Cellulose Hybrid Floor Insulation

- Condensing Gas Furnaces

- Heat

Pump Water Heaters – Site

built

- Hi-R

wall Systems (Foam Sheathing + Icynene) – Site

Built

Research Support

ASHRAE :

During Year 5, in the capacity of chairing ASHRAE’s 6.2 Technical committee, BAIHP staff directed

a major effort to revise Chapter 9 of the ASHRAE Systems

Handbook, “Design of Small Forced-air Heating and

Cooling Systems.” The revisions to the chapter, which

incorporated BAIHP research, were accepted by the committee,

and forwarded to ASHRAE for publication. In year 6 BAIHP

staff provided assistance to other BA teams to improve

chapter 43 of the ASHRAE Applications Handbook – Envelopes.

BAIHP staff have also participated in ASHRAE research projects, conferences,

symposiums, seminars and forums, including:

- Authoring a paper on duct leakage, which was submitted

and approved for presentation at ASHRAE summer meeting

in Year 5.

- Making

a presentation at the ASHRAE summer meeting in Year

4, “Uncontrolled Air Flow

in Small Commercial Buildings.”

- Moderating

a forum on HVAC experiences in HUD code housing at

ASHRAE’s summer meeting

in Year 3. 20 industry and building science professionals

participated in the forum.

- Co-chairing

ASHRAE’s Technical Committee 6.3 – Residential

Forced Air Heating and Cooling Equipment, which is responsible

for ASHRAE standard 152 – Thermal Distribution

Systems.

- Building America research on ductwork and HVAC systems

will be included in the next version of the ASHRAE

standards. Building America research will also be a part

of future efforts in TC 6.3.

NFPA-501: BAIHP continues to support the NFPA standards

process. The NFPA standard is typically incorporated into

the HUD code, which governs the construction of over 250,000

HUD code homes each year.

- In Year 5, BAIHP staff integrated BAIHP duct leakage

and cost data into proposals to the NFPA-501 committee.

Based on this data, NFPA approved a new standard on duct

tightness, as well as a refined duct testing protocol.

- In Year 4, BAIHP staff cited Building America research

and demonstration efforts in support of additional successful

proposals for standards revision, including duct testing,

and use of mastic in duct sealing.

ACEEE :

- BAIHP

staff have co-authored two papers presented at ACEEE

Conferences, “Pushing the Envelope: A

Case Study of Building the First Manufactured Home Using

Structural Insulated Panels,” and “Washington

State Residential Ventilation and Indoor Air Quality

Code (VIAQ) - Whole House Ventilation Systems Field Research

Report.”

- In year 6, BAIHP staff coordinated 24 peer reviewed

papers for the Residential technologies track at the

Summer Study and coordinated informal sessions on HUD-code

housing.

National Institute of Standards and Technologies

(NIST): BAIHP staff continues to work with NIST

staff and industry representatives to evaluate ventilation

and IAQ issues in HUD code homes.

- BAIHP staff also worked with NIST and the Energy

Conservancy to perform tests on a typical HUD code model

house on the NIST campus in Gaithersburg, Maryland. Testing

indicates low flow rates of the whole house ventilation

system and significant duct leakage.

- In Year 6, discussions with NIST, LBL, Ecotope and

Energy Conservatory continued on a retrofit research

effort with Dupont Tyvek, and development of new ventilation

system controls with Panasonic. These discussions will

continue in year 7.

National Manufactured Housing Research Alliance (MHRA): BAIHP

staff continues to participate on MHRA’s ENERGY STAR

committee, which is developing Quality Assurance procedures

with USEPA on ENERGY STAR manufactured homes. An article

on the ZEMH appeared in the MHRA newsletter. WSU worked

with MHRA to provide an article on the ZEMH project. WSU

continues to provide technical support to MHRA on ENERGY

STAR and other building science/energy related efforts

such as the MHI roadmap.

Portable Classrooms

During Years 1 through 4, BAIHP staff conducted a major

effort to promote the adoption of energy efficient portable

classrooms in the Pacific Northwest. BAIHP staff from Washington,

Oregon and Idaho studied both new, energy efficient portable

classrooms and a retrofitted classroom (originally built

in the 1970s).

As a result of these studies and additional computer

modeling, project staff developed a series of energy-efficient

guidelines for portable classrooms in the Pacific Northwest.

These guidelines cover the procurement, set-up and commissioning

of new portable classrooms, as well as the retrofitting

of existing portable classrooms.

The project final report and guidelines are available

on the project website:

http://www.energy.wsu.edu/projects/building/portable_prj.cfm

As part of a separate Building America project, former

BAIHP staff are continuing to provide outreach on efficient

portable classrooms, based on the BAIHP efforts.

Appendix A LIST OF PEER REVIEWED PAPERS PRODUCED

UNDER BAIHP ACEEE Conner, Lubliner, et. al. Invited paper, presented at

2004 ACEEE Summer Study Update of Energy Efficiency Requirements

for Manufactured Homes Baechler,

M.; Lubliner, M; Gordon, A. “Pushing the

Envelope: A Case Study of Building the First Manufactured

Home Using Structural Insulated Panels” – Invited

paper, presented at ACEEE Summer Study, Year 3. Lubliner,

M; Kunkle, R; Devine, J; Gordon, A. “Washington

State Residential Ventilation and Indoor Air Quality Code

(VIAQ) - Whole House Ventilation Systems Field Research

Report” – Invited paper, presented at ACEEE

Summer Study, Year 3. AIVC Lubliner,

Douglass, Parker, Chaser, Performance and Application

of Gossamer Wind ™ Solar Powered Ceiling Fans,

presented at the 25 th AIVC conference Year 6 Lubliner,

M.; Gordon, A.; Persily, A.; Moyer, N.; Richins, W.;

Blakeley, J. “Building Envelope, Duct Leakage

and HVAC System Performance in HUD-Code Manufactured Homes” – Invited

paper, presented at the 23 rd annual AIVC conference,

Year 4. Lubliner,

M; Gordon, A.“Ventilation in US Manufactured

Housing” – Invited paper, presented at the

21 st annual AIVC conference, Year 1. American Solar Energy Society (ASES) Lubliner,

M.; Hadley, A.; Gordon, A. “Introducing

Solar ready Manufactured Housing” – invited

paper, published and presented at ASES conference, Year

6. Lubliner,

M; Nelson, M; Parker, D. “Gossamer Wind

Solar Power Ceiling Fan” – invited paper,

presented at ASES conference, Year 5. ASHRAE Lubliner,

M.; Gordon, A.; Hadley, A. “Manufactured

Home Performance; Comparing Zero Energy and ENERGY STAR”.

Invited paper, submitted to Whole Buildings IX International

Conference, published and presented in Year 6. ASHRAE

Std 152 Sub-committee. ASHRAE 2004 Standard 152 - MOT

to Determine the Steady State and Seasonal Efficiency

of Residential Thermal Distribution Systems. – Year

6 Lubliner,

M.; et. al. ASHRAE 2004 Systems and Equipment Handbook

chapter 9 – Residential and Small Commercial

HVAC Systems. Year 6. Hales,

D; Lubliner, M; Gordon, A. “Duct Leakage

in New Washington State Residences: Findings and Conclusions” – Invited

paper, presented at ASHRAE Summer Meeting, Year 5. Automated Builder Magazine Baechler,

M; Gordon, A. “Northwest Portable Classroom

Study”, Year 5. Gordon,

A.; Lubliner M. “Zero Energy Manufactured

Home”, Year 5. Manufactured Housing Research Alliance Lubliner. “Zero Energy Manufactured Home”,

Year 5. National Fire Protection Association NFPA-501

2004 MEC. Standard on Manufactured Housing – Mechanical

Chapter NFPA-501

2002 MEC. Standard on Manufactured Housing – Mechanical

Chapter NFPA-501

1999 MEC. Standard on Manufactured Housing – Mechanical

Chapter

Appendix B

BAIHP Workproducts

Included on separate CD, which includes:

- Papers – AIVC,

BTECC, ASES

- Example of Problem Home report

- Example

of ¼ inspection report

- Billing Analysis report

- Benchmarking Report

- Power Point Presentations

- Trip Reports

- New Technology Summary Report

- Fleetwood

duct leakage “pressure box” test

report

- Fleetwood Belly Moisture Tests data analysis results

|

You

are here: >

You

are here: >